Machining equipment capable of carrying out secondary stamping forming on metal raw materials

A technology for secondary stamping and processing equipment, applied in the field of metal stamping, can solve the problems of low stamping processing efficiency, high labor intensity, safety accidents, etc., and achieve the effect of reducing labor intensity, reducing manual operations, and reducing accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

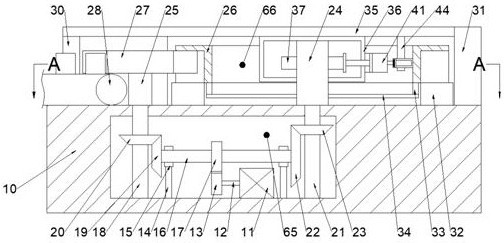

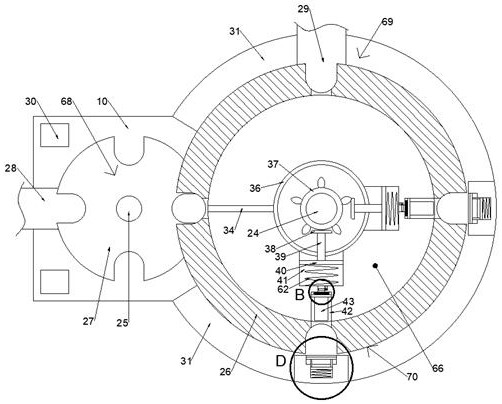

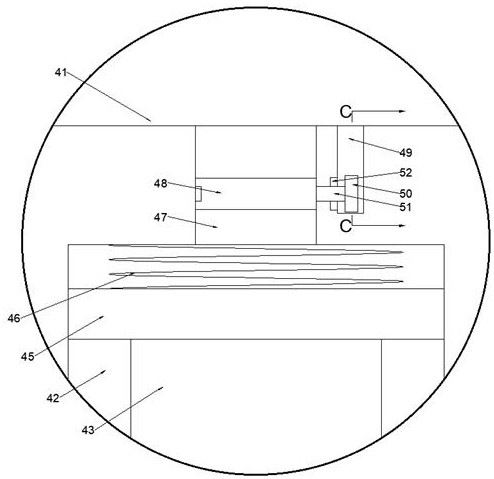

[0019]Bonded belowFigure 1-5The present invention will be described in detail, in which it is convenient for the description, the orientation of the following statement is as follows: The above-mentioned left and right directionsfigure 1 The projection relationship of the projection is consistent with the front and back and so on.

[0020]A processing apparatus capable of secondary pressing of metal raw materials, including a body 10, the body 10, with two support columns 30 and a fixed wall on the upper side surface of the body 10. 31. The support column 30 and the upper surface of the fixing wall 31 are tapered, and the upper side surface of the body 10 is fixed with an external transport belt 28, which can be The stamping workpiece is delivered to the device, and the upper side surface of the body 10 is fixed, and the upper side slides on the upper side surface of the fixed ring 32, and the large rotating disk 26 is provided with a stamping chamber 66, the top plate. 35 The lower side

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap