Combustion supporting air heating and energy storing energy-saving roller kiln

A technology of combustion-supporting air and roller kiln, which is applied in the field of roller kiln, can solve the problems of reducing the thermal efficiency of products, waste heat, and large temperature drop, and achieve the effect of reducing the energy consumption of the kiln and reducing the heat loss to the outside.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

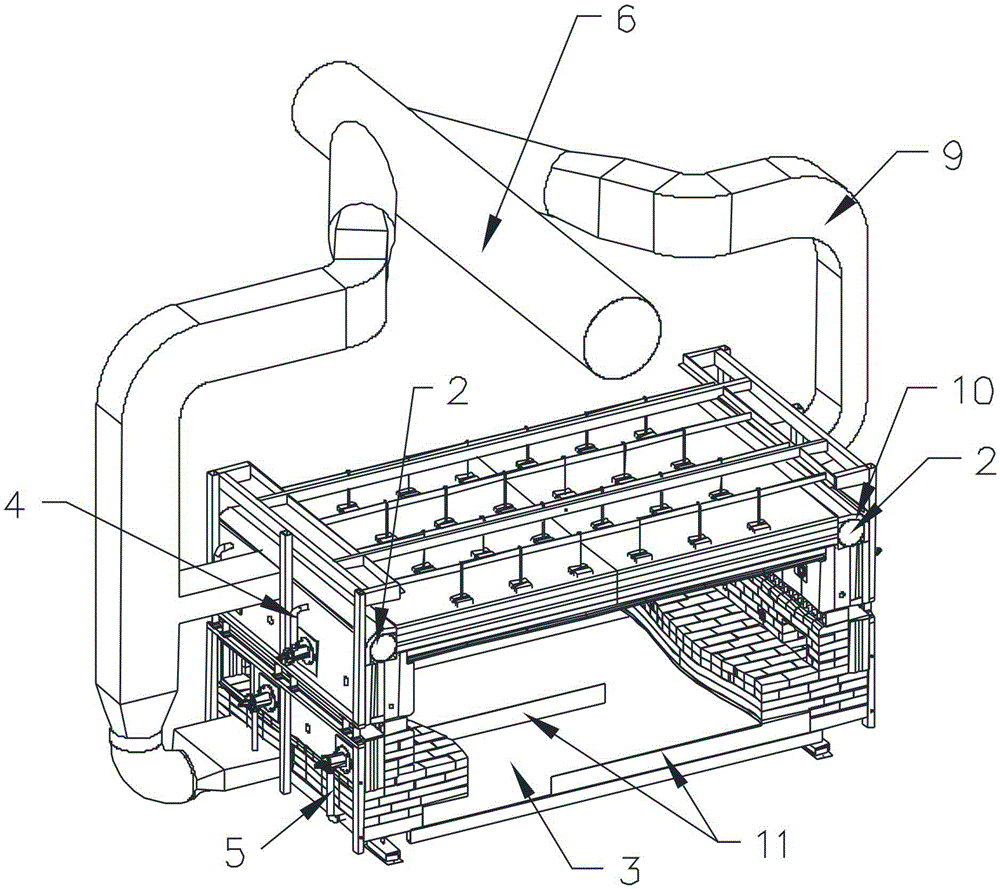

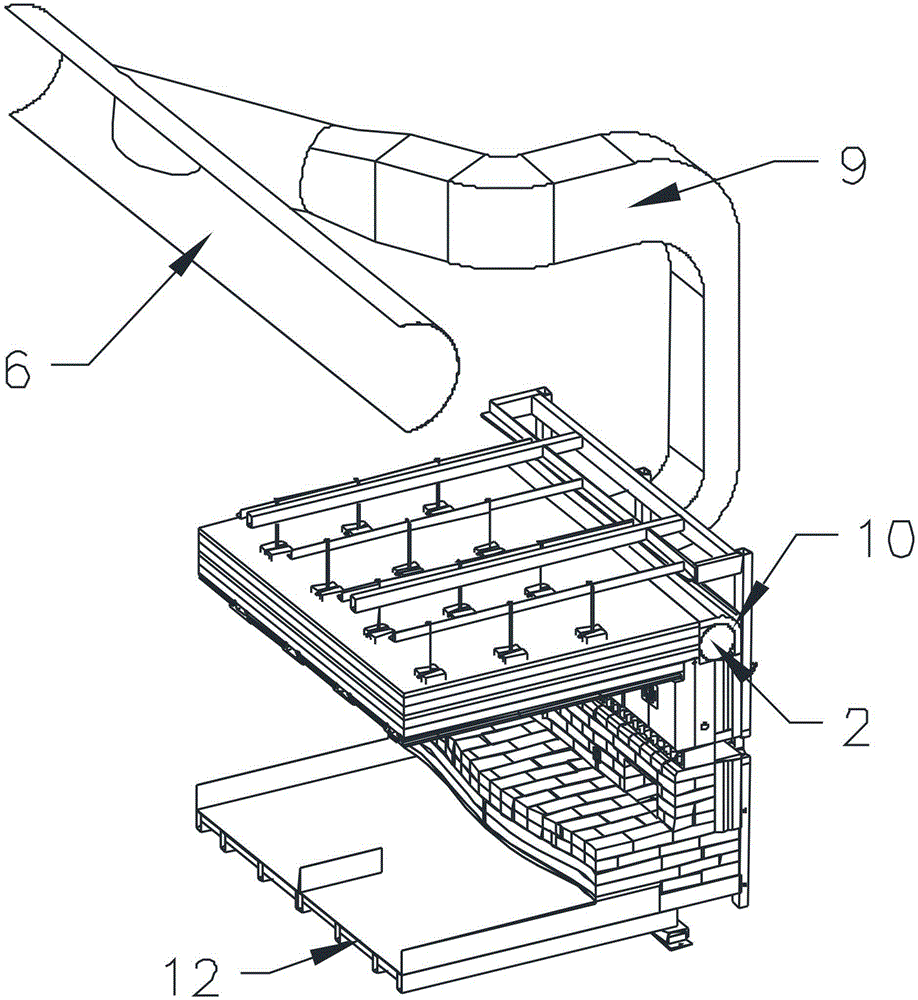

[0015] Since the present invention mainly solves the structural improvement of the preheating and firing zone, the drawings and descriptions mainly revolve around the preheating and firing zone, and the remaining parts are omitted.

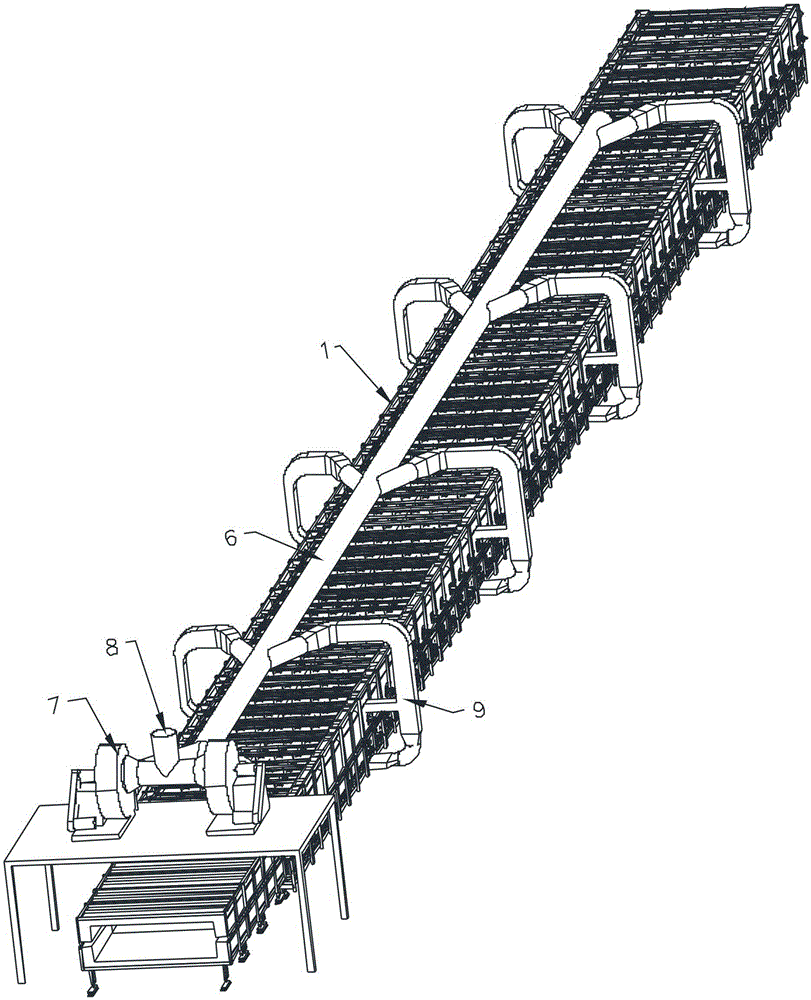

[0016] Such as Figure 1-3 As shown, the energy-saving roller kiln preheating and firing zone of the combustion-supporting air heating energy storage of the embodiment of the present invention includes a preheating and firing belt kiln body 1, and a refractory kiln body 1 is provided around the inner wall of the preheating and firing belt kiln body 1. Insulation material, the above two sides of the preheating and firing zone kiln body 1 are located in the refractory insulation material, and the upper combustion-supporting air duct 2 extending along the preheating and firing zone kiln body 1 is arranged, and the preheating and firing zone Kiln body 1 The refractory insulation material at the bottom of the kiln is provided with a lower combustion-suppo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap