3D printing tissue engineering scaffold and preparation method thereof

A tissue engineering scaffold and 3D printing technology, applied in 3D printing, metal processing equipment, additive manufacturing, etc., can solve the problems of difficult loading of growth factors, difficulty in one-time molding of hydrogel materials and medical polymer materials, etc., and achieve mechanical good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023] The present invention also provides a preparation method of the claimed 3D printing tissue engineering scaffold, which includes the following steps:

[0024] S1: Preparation of artificial medical polymer-hydrogel composite microspheres series with gradient content of calcium and phosphorus active biomaterials: Synthesize hydrogel microspheres containing KGN, and wrap different contents of calcium and phosphorus on the outside of the hydrogel microspheres Active biological materials and artificial medical polymer materials to obtain artificial medical polymer-hydrogel composite microspheres;

[0025] S2: Design a three-dimensional model of the porous multi-level structure through software modeling;

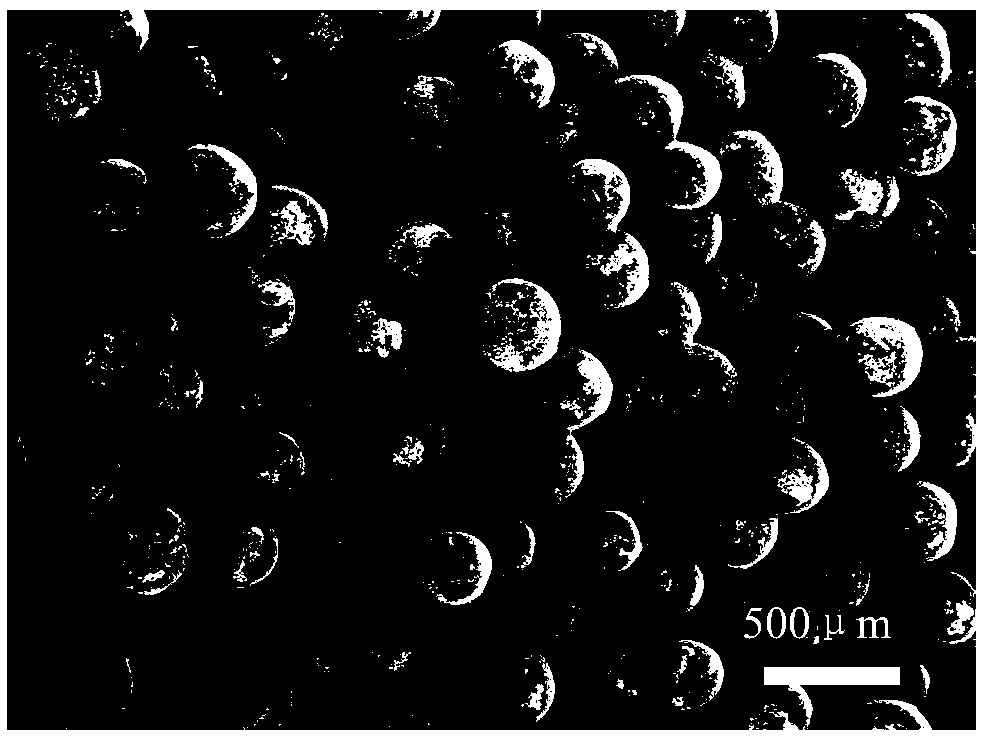

[0026] S3: Using the selective laser sintering rapid prototyping technology, the series of artificial medical polymer-hydrogel composite microspheres are sintered layer by layer according to the model to obtain a porous laminate with a layer-by-layer gradient change in the cont

Example Embodiment

[0036] Example

[0037] S1: Preparation of a series of artificial medical polymer-hydrogel composite microspheres with gradient changes in the content of calcium and phosphorus active biomaterials. The series of artificial medical polymer-hydrogel composite microspheres refers to the artificial medical polymer-hydrogel composite microspheres corresponding to different layers in the porous laminated structure. In this embodiment, the porous laminated structure is preferably configured to include three layers, namely a shallow layer, a transition layer and a bottom layer. The artificial medical polymer-hydrogel composite microsphere series includes a shallow layer of artificial medical polymer-hydrogel composite microspheres, a transition layer of artificial medical polymer-hydrogel composite microspheres and a bottom layer of artificial medical polymer-hydrogel composite microspheres. Gel composite microspheres.

[0038] First prepare the shallow artificial medical polymer-hydro

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap