Preparation method of polyolefin nanometer composite material

A nano-composite material and polyolefin technology, applied in the field of preparation of polyolefin nano-composite materials, can solve the problems of low preparation efficiency, large amount of ash, restricting the performance of materials, etc., and achieve the effect of uniform dispersion of nano-fillers and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] Example 1:

[0026] The preparation method of polyolefin nanocomposite includes the following steps:

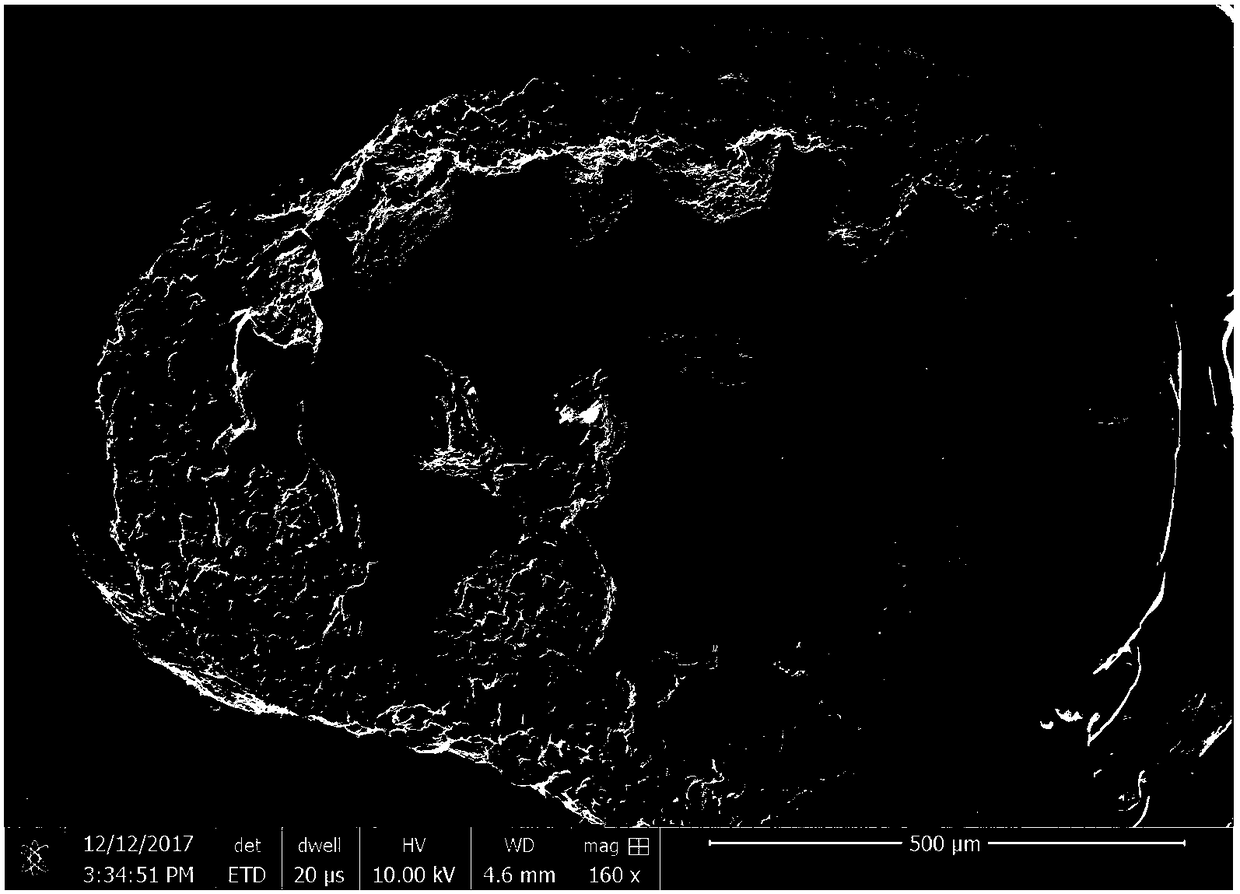

[0027] (1) Provide 10g of polyethylene particles with a pore volume of 1.5mL / g. The porous structure inside the primary particles is as figure 1 As shown; (2) 7.125g TiCl 4 After mixing with 10 mL of toluene, add the polyethylene particles in step (1) and immerse for 108 hours to obtain TiCl 4 / Polyethylene particles / toluene mixed solution; (3) TiCl 4 / Polyethylene particles / toluene mixed solution, after freezing with liquid nitrogen, vacuum drying, until the mixed solution is thawed, re-freeze with liquid nitrogen and slowly dry, cycle 20 times to obtain dry particles; (4) 100mL concentration The 2mol / L hydrochloric acid / ethanol solution is steamed into the dried particles obtained in step (3) in the form of steam, and the steam entering rate is 0.1mL / min to obtain steam-fumigated particles; (5) steam-fumigated particles Wash 5 times with water and fully dry t

Example Embodiment

[0028] Example 2:

[0029] The preparation method of polyolefin nanocomposite includes the following steps:

[0030] (1) Provide 10g of polyethylene particles with a pore volume of 1.5mL / g. The porous structure inside the primary particles is as figure 1 As shown; (2) 2.375g TiCl 4 After mixing with 5mL of toluene, add the polyethylene particles in step (1) and immerse for 24h to obtain TiCl 4 / Polyethylene particles / toluene mixed solution; (3) TiCl 4 / Polyethylene granules / toluene mixed solution, after freezing with liquid nitrogen, vacuum drying, until the mixed solution is thawed, re-freezing with liquid nitrogen and slowly drying, cycle 5 times to obtain dry particles; (4) 100mL concentration The 0.1mol / L hydrochloric acid / ethanol solution was steamed into the dried particles obtained in step (3) in the form of steam, and the steam entering rate was 0.1mL / min to obtain the steam-fumigated particles; (5) the steam-fumigated particles The particles were washed once w

Example Embodiment

[0031] Example 3:

[0032] The preparation method of polyolefin nanocomposite includes the following steps:

[0033] (1) Provide 10g polypropylene particles with a pore volume of 0.01mL / g; (2) Add 4.0g TiCl 3 After mixing with 0.1mL of tetrahydrofuran, add the polypropylene particles in step (1) and immerse for 76h to obtain TiCl 3 / Polypropylene particles / tetrahydrofuran mixed solution; (3) TiCl 3 The mixed solution of polypropylene particles / tetrahydrofuran is frozen with liquid nitrogen and then dried in vacuum. After the mixed solution is thawed, it is frozen again with liquid nitrogen and slowly dried. Cycle 7 times to obtain dry particles; (4) Reduce the concentration of 10 mL The 20mol / L hydrochloric acid / ethanol solution is steamed into the dried particles obtained in step (3) in the form of steam, and the steam entering speed is 10mL / min to obtain the steam-fumigated particles; (5) Use water for the steam-fumigated particles Washed three times and fully dried to

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap