Fire-resistant cable

A fire-resistant cable and wire core technology, applied in the field of fire-resistant cables, can solve the problems of increasing transportation and production costs, increasing weight, etc., and achieve the effects of avoiding the possibility of burning, avoiding short circuits, and preventing burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0016] The present invention will be further described below in conjunction with the drawings. The following embodiments are only used to more clearly illustrate the structure of the present invention.

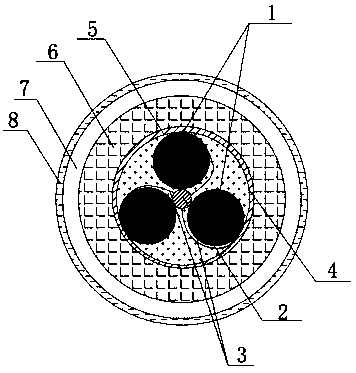

[0017] A fire-resistant cable includes a wire core 1, the wire core 1 includes a plurality of wires, the plurality of wire cores 1 are wound together around a heat conducting rod 2, and the heat conducting rod 2 is provided with a heat conducting fin 3, the heat conducting fin 3 The number of the conductor cores 1 is consistent with the number of the conductor cores 1. The thermally conductive fins 3 are arranged between two adjacent conductor cores 1, and the outside of the conductor cores 1 is covered with a mica tape 4, and the thermally conductive fins 3 The other end of the mica tape 4 is attached tightly to the mica tape 4. The mica tape 4 is covered with a glass fiber tape 5, an insulating layer 6 is provided on the outside of the glass fiber tape 5, and an oxygen barrier lay

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap