Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8 results about "Iodine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iodine is a chemical element with the symbol I and atomic number 53. The heaviest of the stable halogens, it exists as a lustrous, purple-black non-metallic solid at standard conditions that melts to form a deep violet liquid at 114 degrees Celsius, and boils to a violet gas at 184 degrees Celsius. The element was discovered by the French chemist Bernard Courtois in 1811. It was named two years later by Joseph Louis Gay-Lussac from this property, after the Greek ἰώδης "violet-coloured".

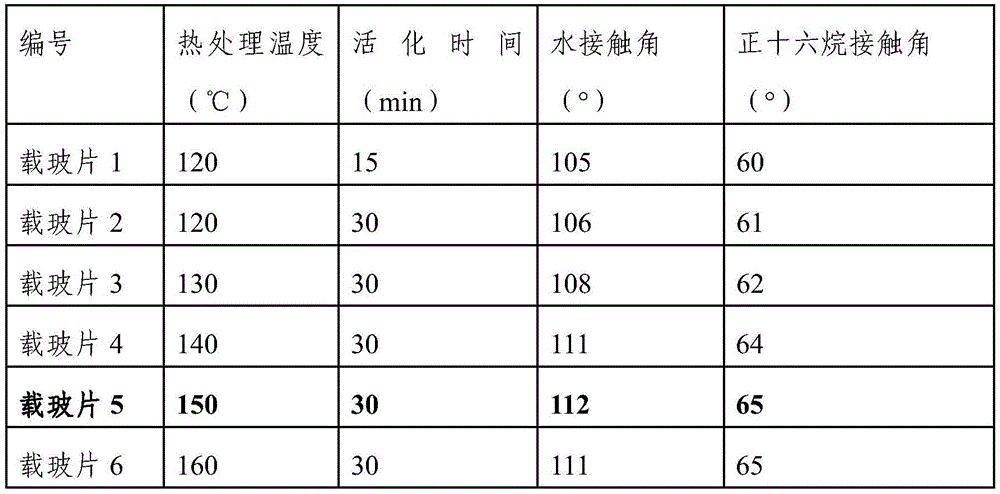

Fluorosilicon waterproof oil repellent, and synthesis method and application thereof

InactiveCN106810684AAchieve the perfect combinationOvercoming AdhesionAntifouling/underwater paintsPaints with biocidesTectorial membraneSilanes

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

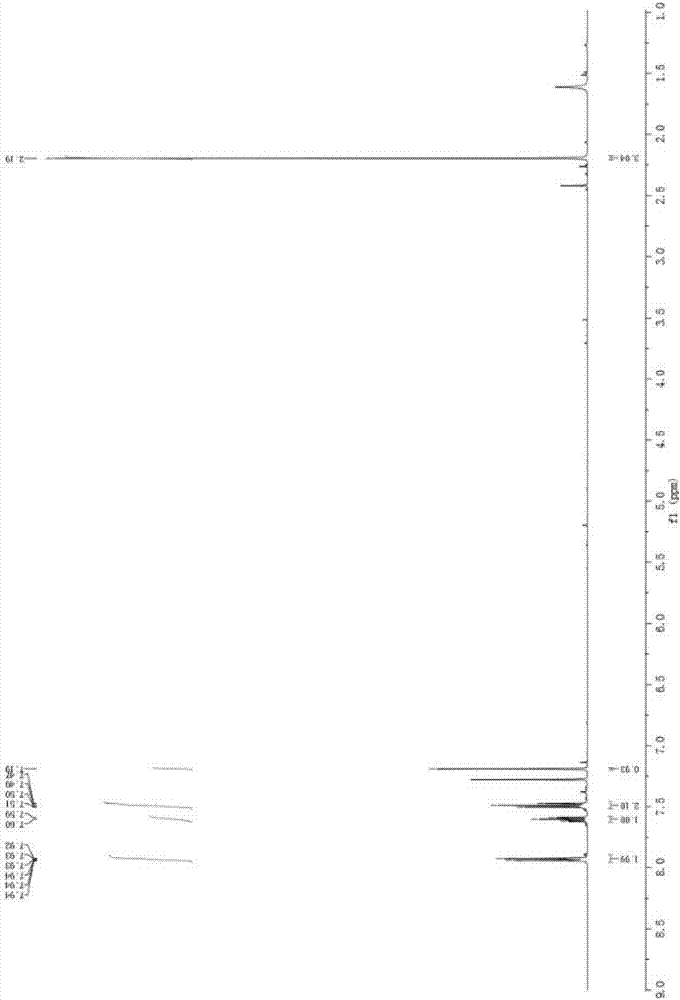

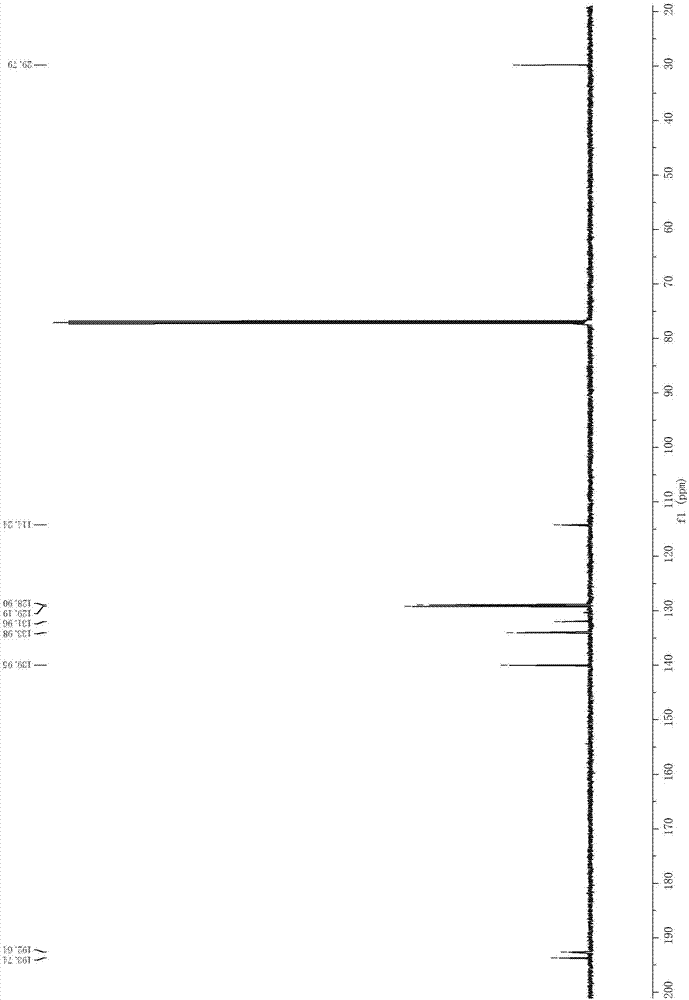

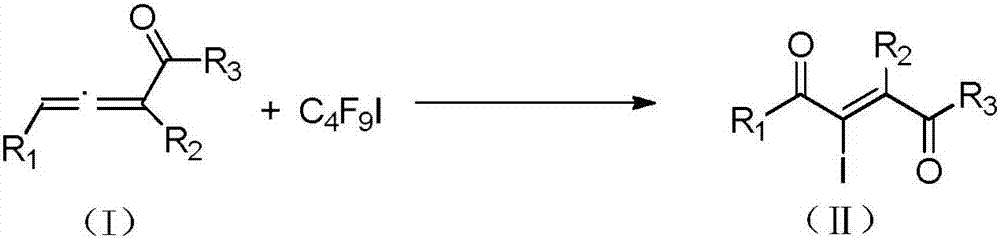

Method for preparing 2-iodine amyl -2-ene-1,4-diketone derivative by adopting visible light catalysis

ActiveCN107011145AMild reaction conditionsEasy to operateOrganic compound preparationCarboxylic acid esters preparationIodidePollution

Owner:ZHEJIANG UNIV OF TECH

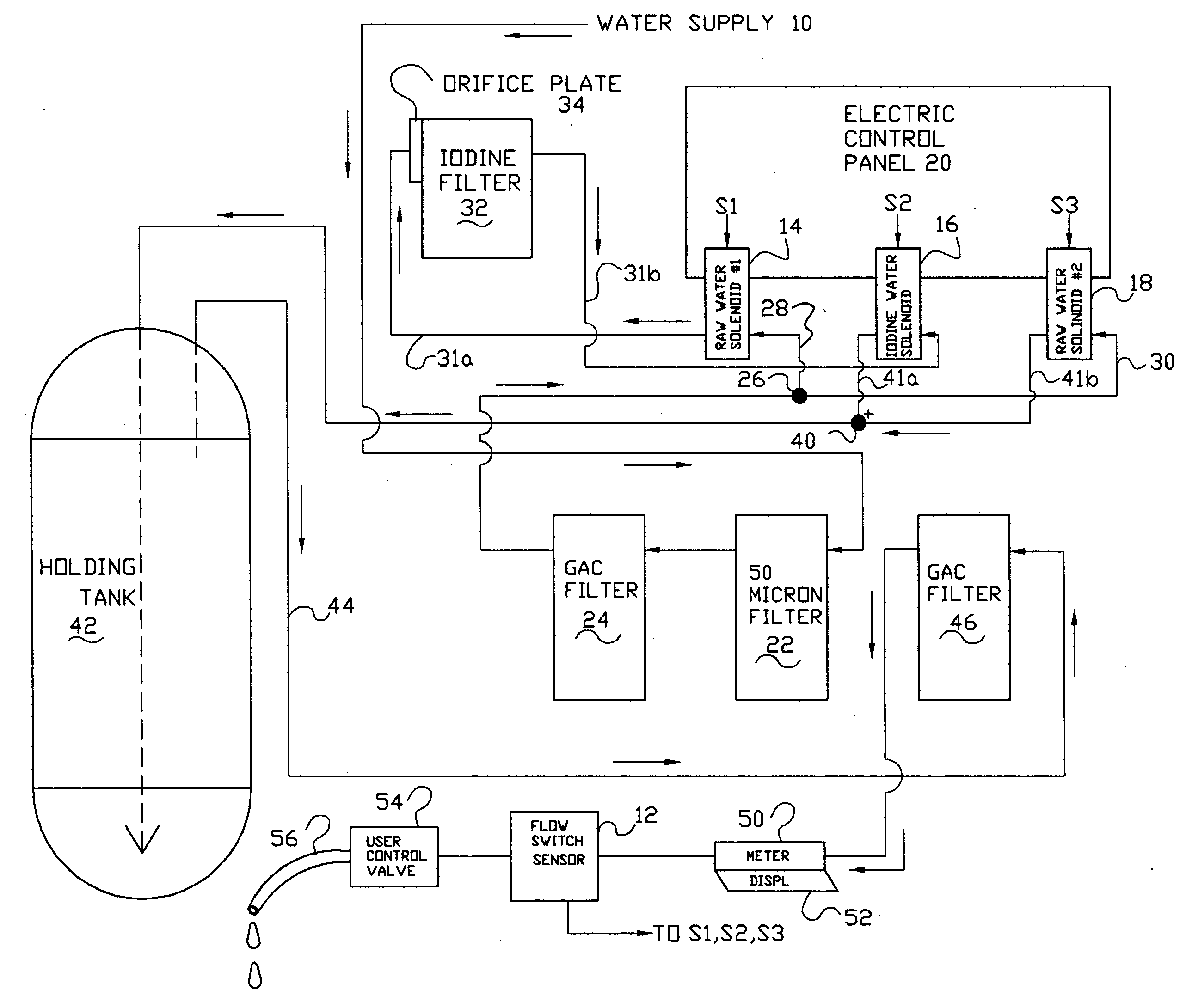

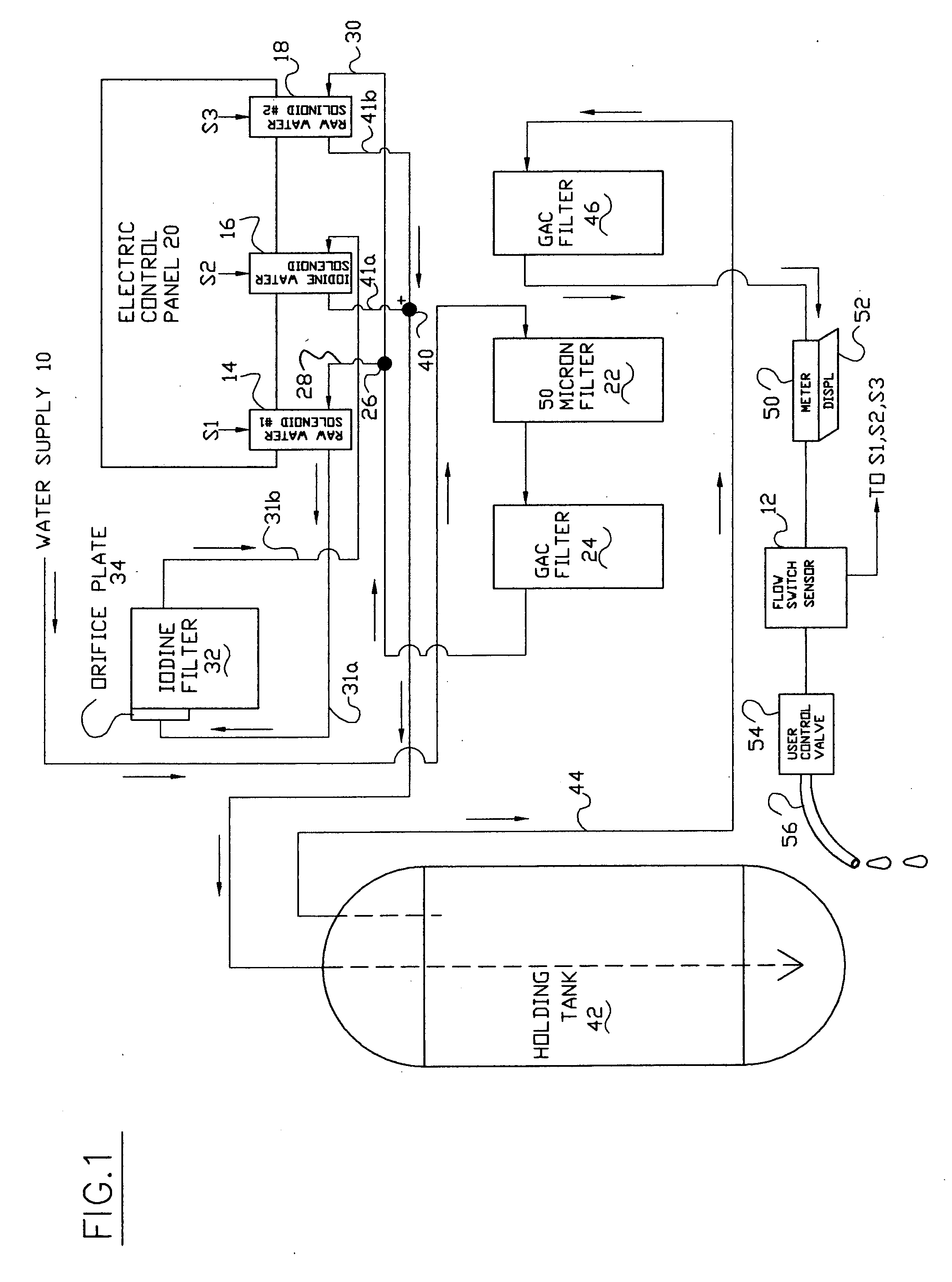

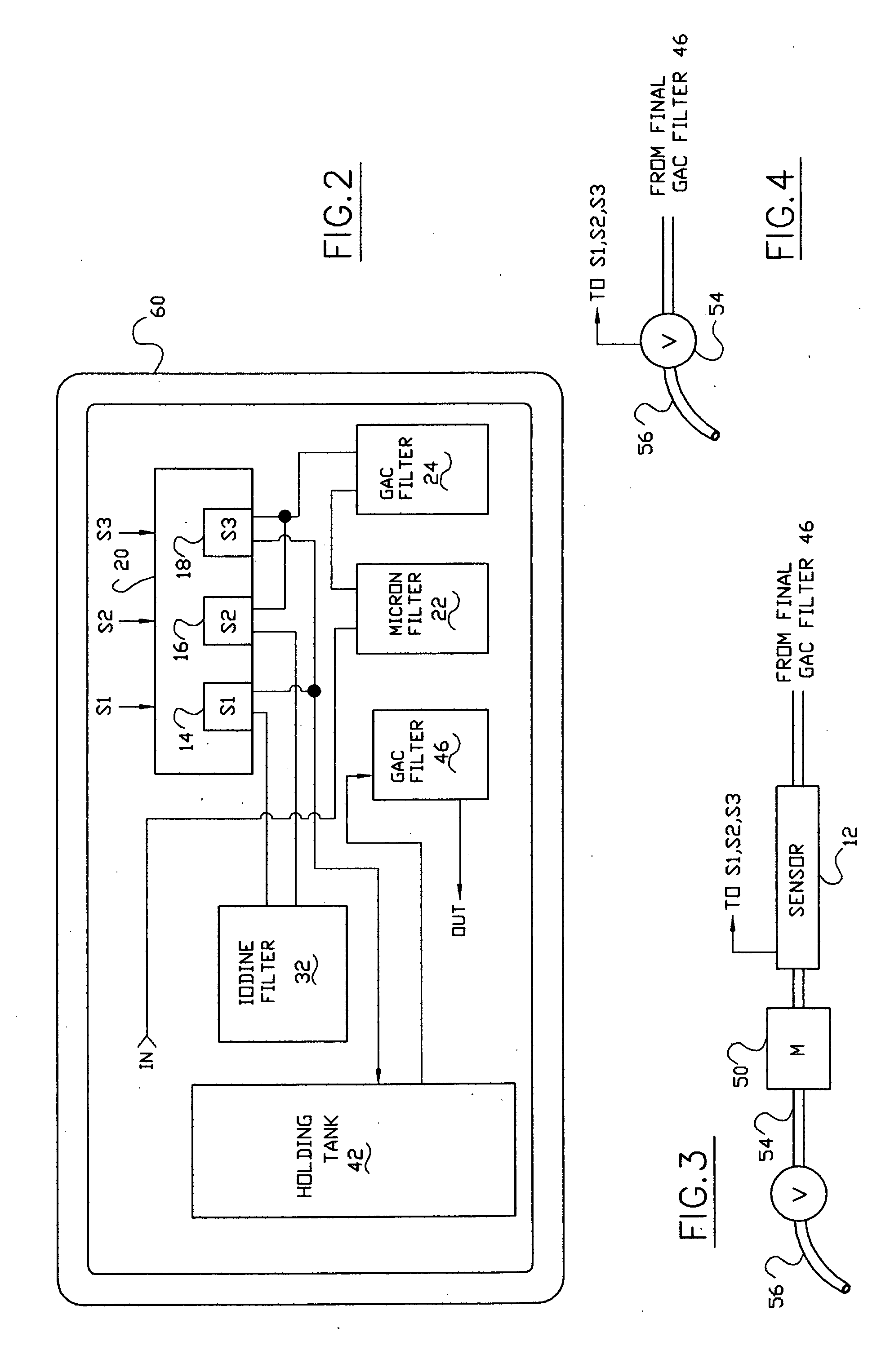

Potable water delivery system with disinfection and residual discharge unit and method

InactiveUS20050109704A1Treatment involving filtrationSolid sorbent liquid separationPotable waterIodine

Owner:PURE H2O BIO TECH

Method for recovering gold from printed circuit board of waste mobile phone

ActiveCN108642289AImprove adsorption efficiencyAchieve reuseOther chemical processesProcess efficiency improvementElectrolysisResource utilization

Owner:NANKAI UNIV

Preparation method of biodegradable fallout radioactive material for treating cancer

InactiveCN101417135AConcentration control of radioactive substancesLow priceRadioactive preparation carriersAntineoplastic agentsBiocompatibility TestingAminolysis

Owner:TONGJI UNIV

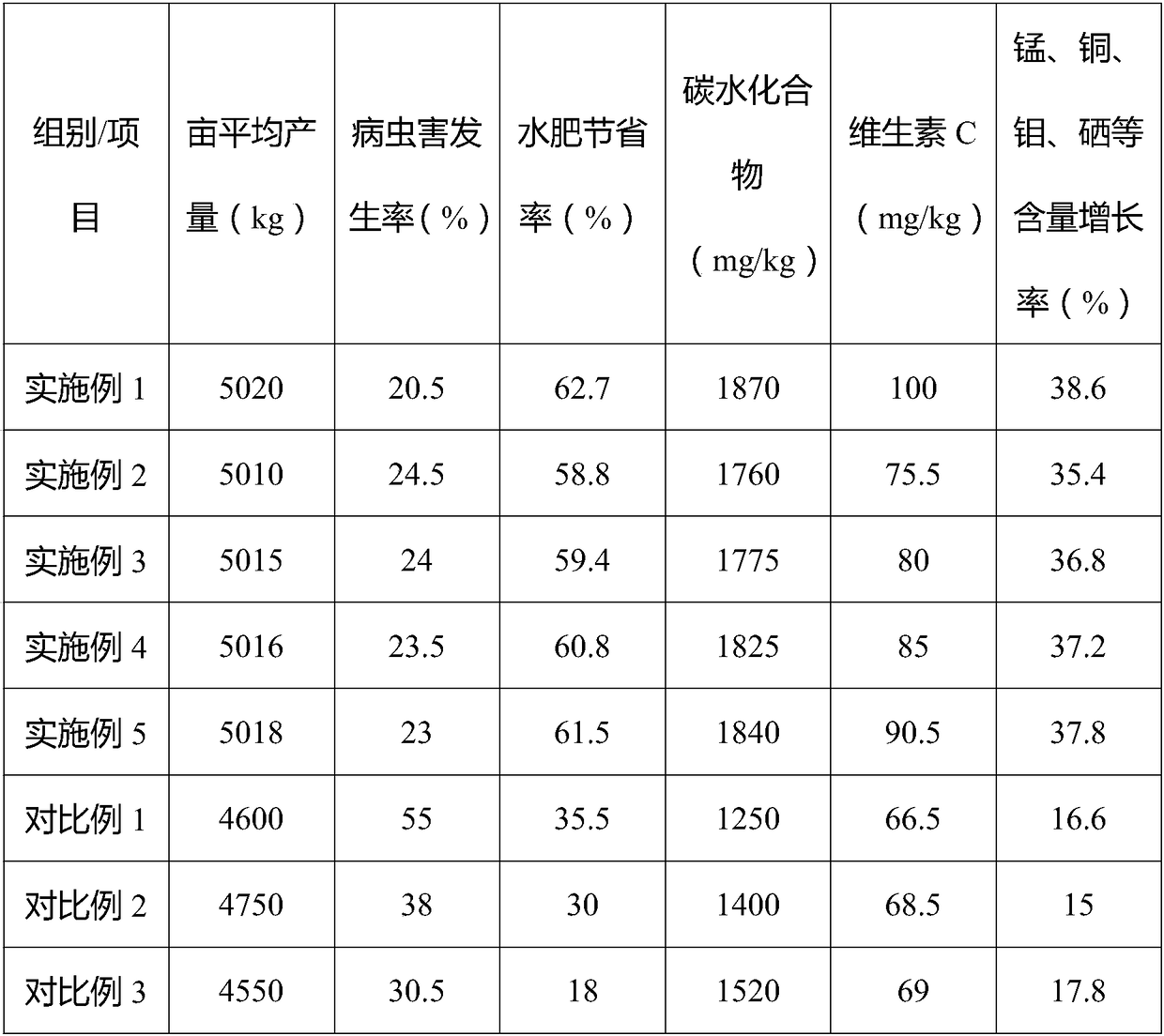

Planting method for beet rich in various trace elements

InactiveCN108739144AReduce volatilityReduce churnBio-organic fraction processingExcrement fertilisersPlant cellManganese

Owner:FOSHAN RIKEWEI FOOD TECH RES INST GENERAL PARTNER

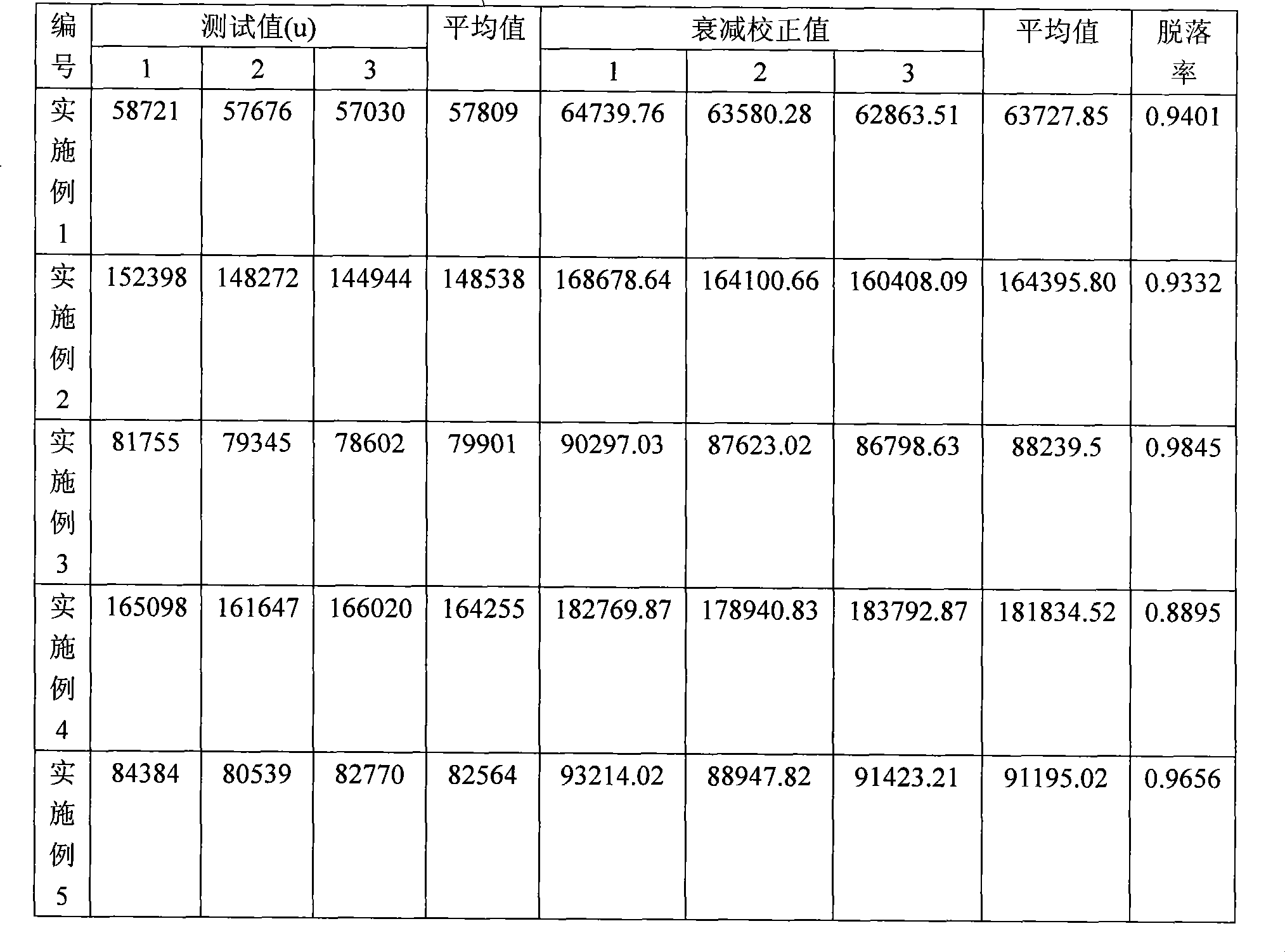

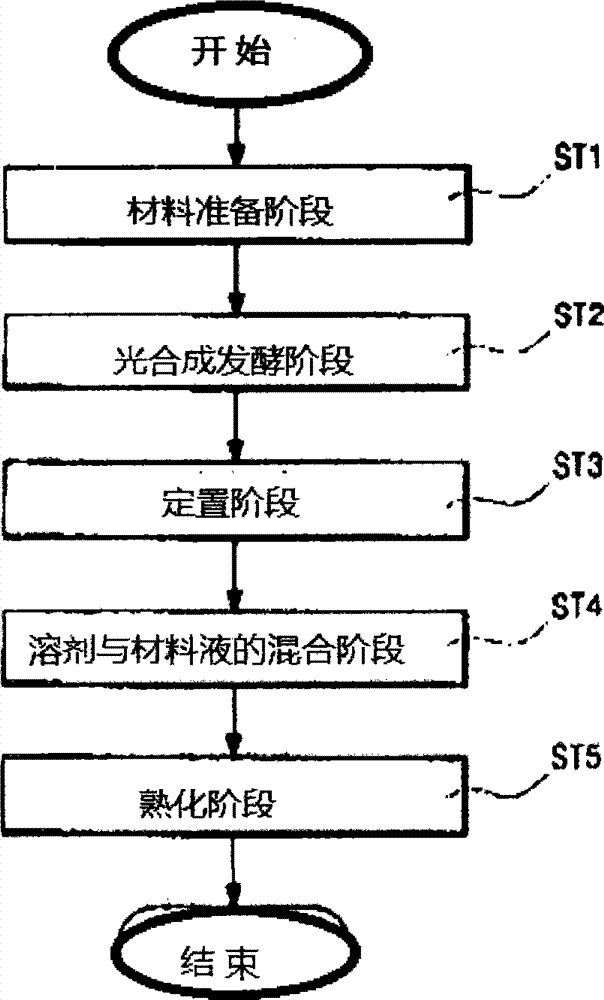

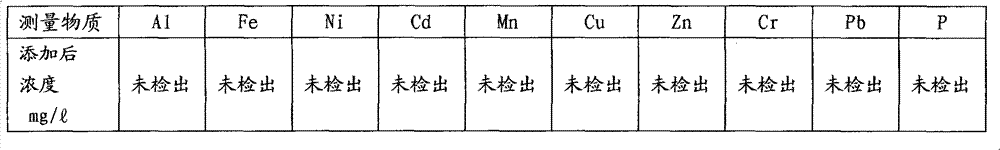

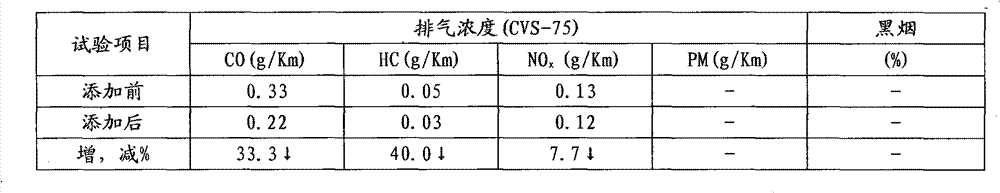

Fuel additive for promoting combustion of liquid fuels and manufacturing method thereof

InactiveCN102952591ASave fuelLower discharge temperatureLiquid carbonaceous fuelsFermentationIodineAtmospheric temperature

Owner:程刚

Vein-iodine rapid detection and diagnosis method for citrus yellow shoot

InactiveCN109765227AIn line with the principle of turning blueEasy to obtainMaterial analysis by observing effect on chemical indicatorMedicineCataphyll

Owner:广西钦州农业学校

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap