Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6 results about "Sand casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sand casting, also known as sand molded casting, is a metal casting process characterized by using sand as the mold material. The term "sand casting" can also refer to an object produced via the sand casting process. Sand castings are produced in specialized factories called foundries. Over 60% of all metal castings are produced via sand casting process.

Large casting lost-foam resin sand casting process

The invention provides a large casting lost-foam resin sand casting process which comprises steps of mould manufacturing, mould assembling, paint spraying and drying, resin sand vibration-filling, bottom-injection type semi-closed casting system applying, a casting clearing process and the like. A large casting lost-foam model is processed in a programmed and digital manner; the mould material replace rare korean pine wood with reproducible low-cost EPS foam, so that a great deal of non-renewable resources are saved; meanwhile, the processing performance and efficiency are greatly improved. A pouring system is designed with a gas exhaust channel, so that complex operations such as operation of eliminating a mould cavity lost mould by adopting methods such as combustion, and the like are avoided, limit in aspect of a metal material of a lost-foam casting process is further broken through, and therefore, the application field is wider.

Owner:YANTAI RUISHENG AUTOMOBILE MOULD CO LTD

Sandblasted slab for up-down sand-shooting full-automatic sand casting molding machine

ActiveCN106424597AMeet the use requirementsGood orientationMoulding machinesMolding machineSand blasting

The invention discloses a sandblasted slab for an up-down sand-shooting full-automatic sand casting molding machine capable of adjusting positions of nozzles. The sandblasted slab comprises a sandblasted slab main body. A plurality of sandblasted slab fixing holes are uniformly formed in two sides of the sandblasted slab main body; the sandblasted slab main body is fixed at a sand outlet of a sand storage box through bolts and the sandblasted slab fixing holes; a plurality of sand outlet holes are uniformly formed in the sandblasted slab main body; screw holes are formed in sandblasting front surfaces of the sandblasted slab main body on two sides of the sand outlet hole; a plurality of nozzles and sand outlet cover plates are arranged on the sandblasting front surfaces of the sandblasted slab main body through screws and screw holes; a sand blasting port is formed in the middle of each of the nozzles; nozzle fixing screw holes matched with the screw holes are formed in two sides of each of the nozzles; cover plate fixing screw holes matched with the screw holes are formed in two sides of the sand outlet cover plate; and a plurality of triangular guiding ribs are uniformly arranged on the back surface of the sandblasted slab main body.

Owner:ZHUOJIE (JIANGSU) IND INTELLIGENT EQUIP CO LTD

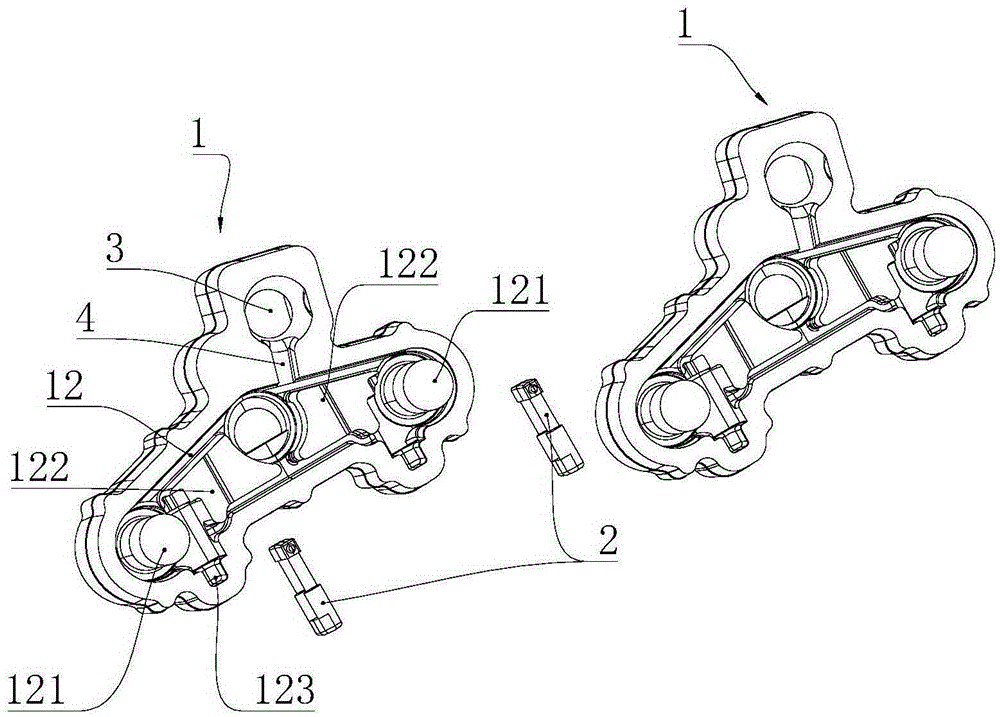

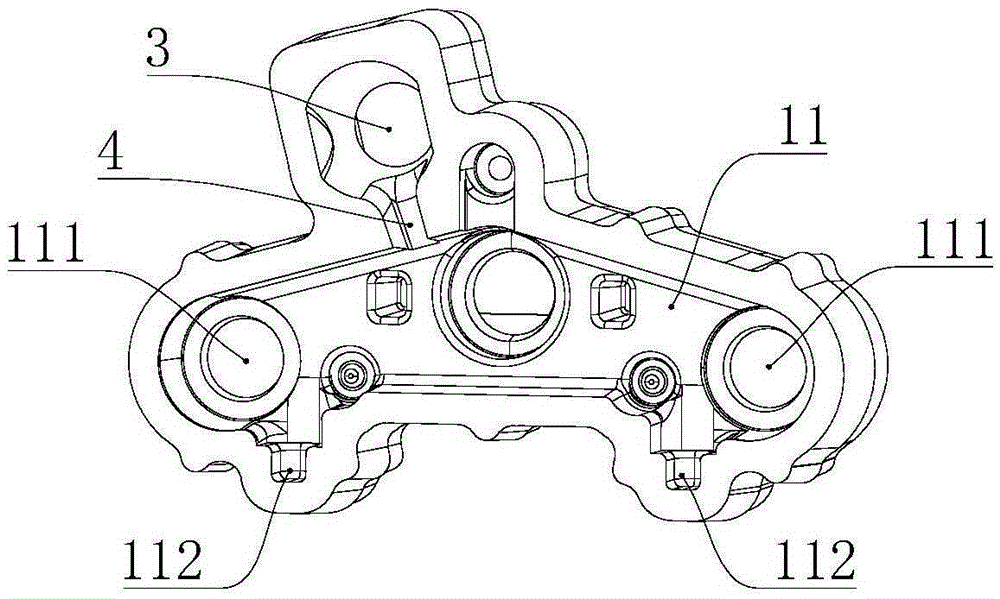

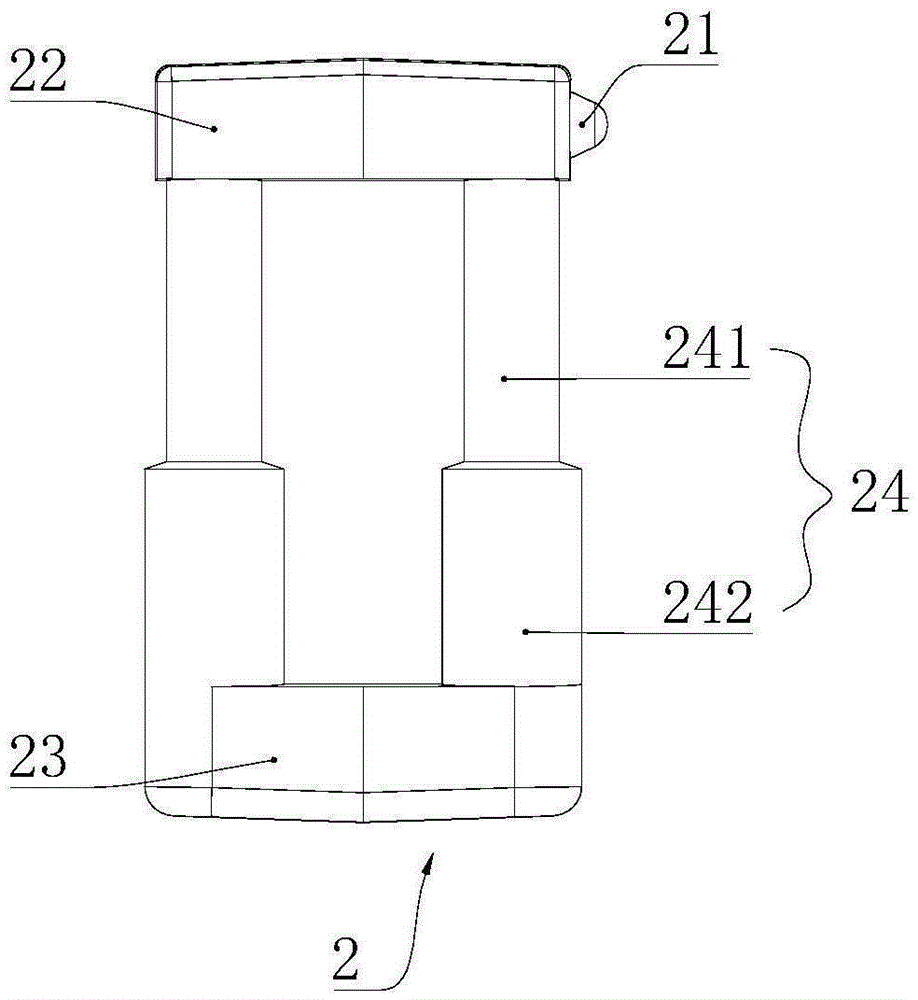

Sand casting die for casting of lower connecting plate

PendingCN105364000AShort cycleIncrease the number of permutationsFoundry mouldsFoundry coresSand castingMaterials science

Owner:张越

Sand casting mold and method for preparing bucket tooth tip by using sand casting mold

InactiveCN109047645AImprove breathabilityHigh strengthFoundry mouldsFoundry coresSand castingCasting mold

The invention relates to a sand casting mold and a method for preparing a bucket tooth tip by using the sand casting mold, belonging to the technical field of machinery. The sand casting mold is prepared from the following raw materials in parts by weight: 100 parts of modified quartz sand, 12-30 parts of wollastonite, 4-6 parts of calcium bentonite, 1-4 parts of pulverized coal, and 6-9 parts ofwater. The sand casting mold has the advantages of good air permeability and good performance, and can provide molten metal with good flowability and reduce surface defects of castings, and the buckettooth tip by using the casting mold can effectively improve the mechanical properties thereof.

Owner:NINGBO JIADA PRECISION CASTING

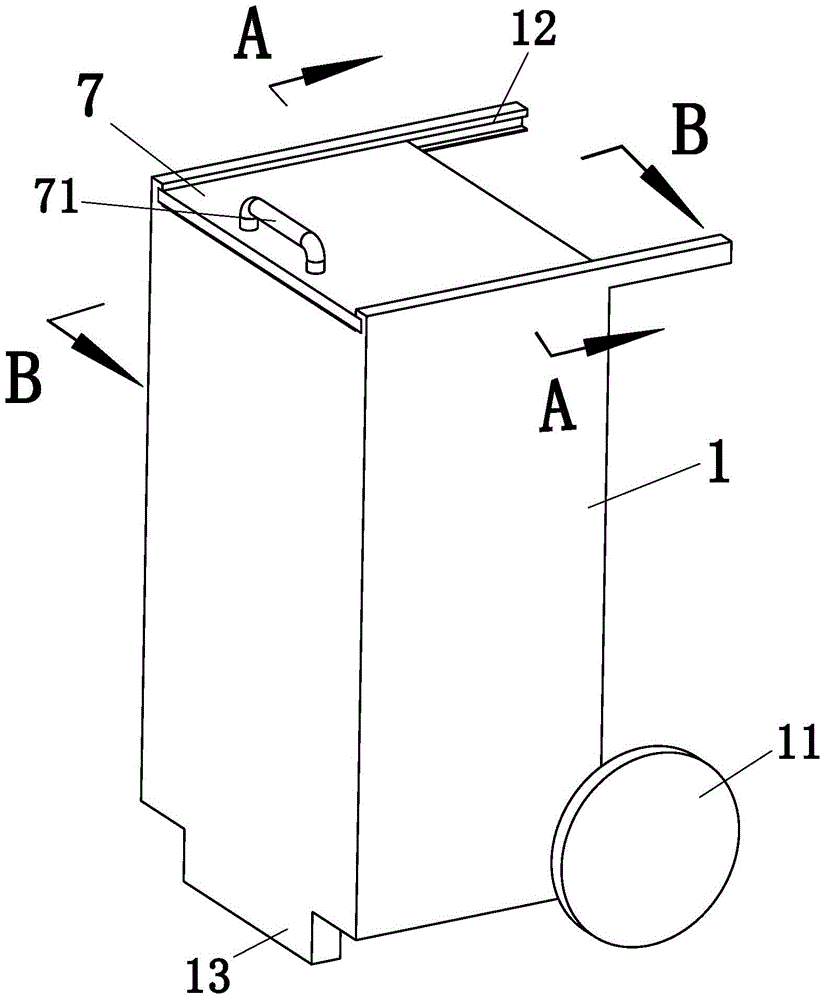

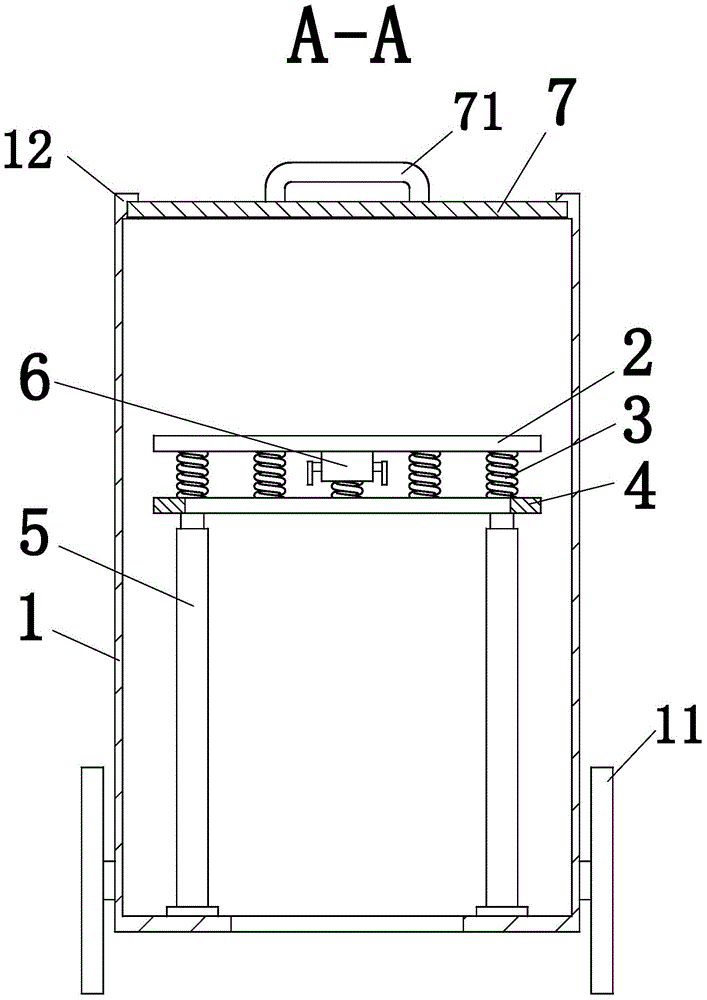

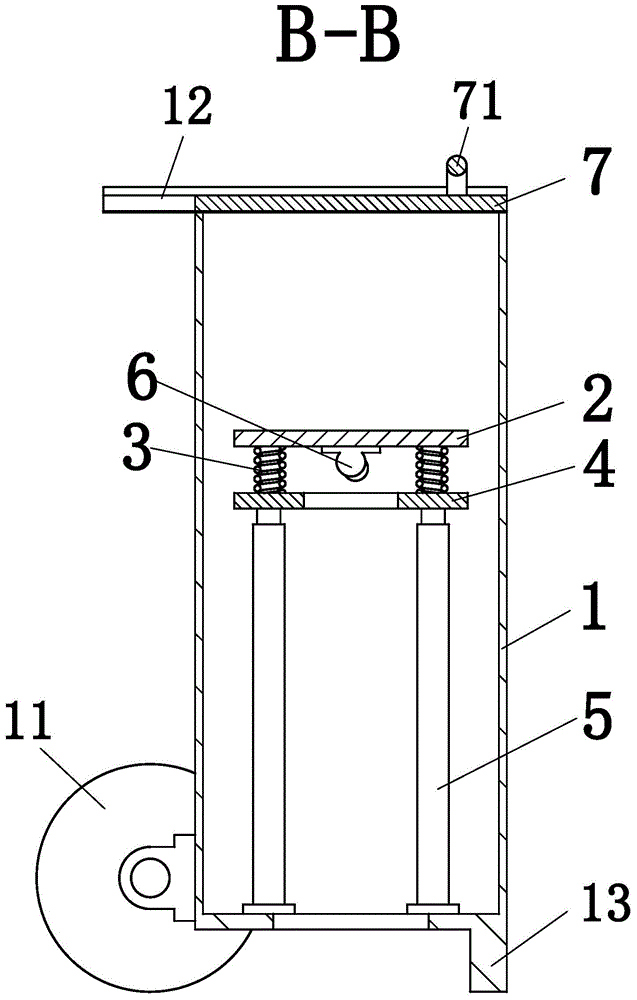

Movable micro-vibration squeeze compaction molding machine

Owner:安庆旭东工贸有限责任公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap