Anti-backfire nozzle for rocket engine

A rocket engine, anti-backfire technology, applied in rocket engine devices, machines/engines, mechanical equipment, etc., can solve problems such as no explanation or report found, and data not yet collected, so as to suppress the spread of flames upstream, enhance Anti-tempering function, the effect of enhancing the anti-tempering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several changes and improvements without departing from the concept of the present invention. These all belong to the protection scope of the present invention.

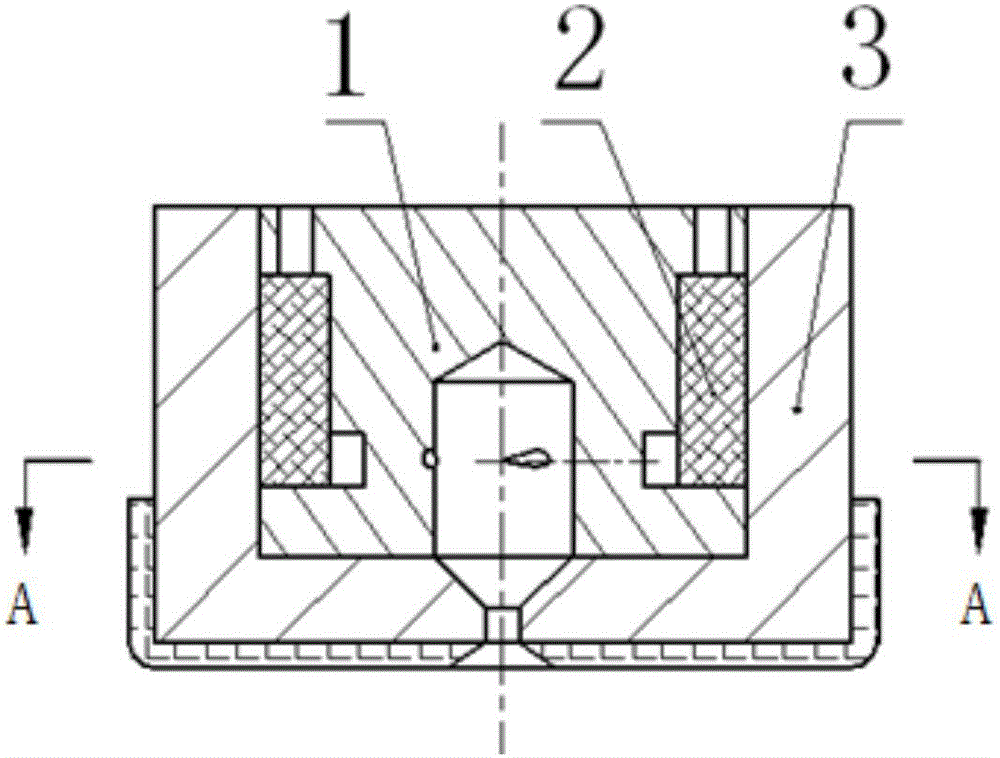

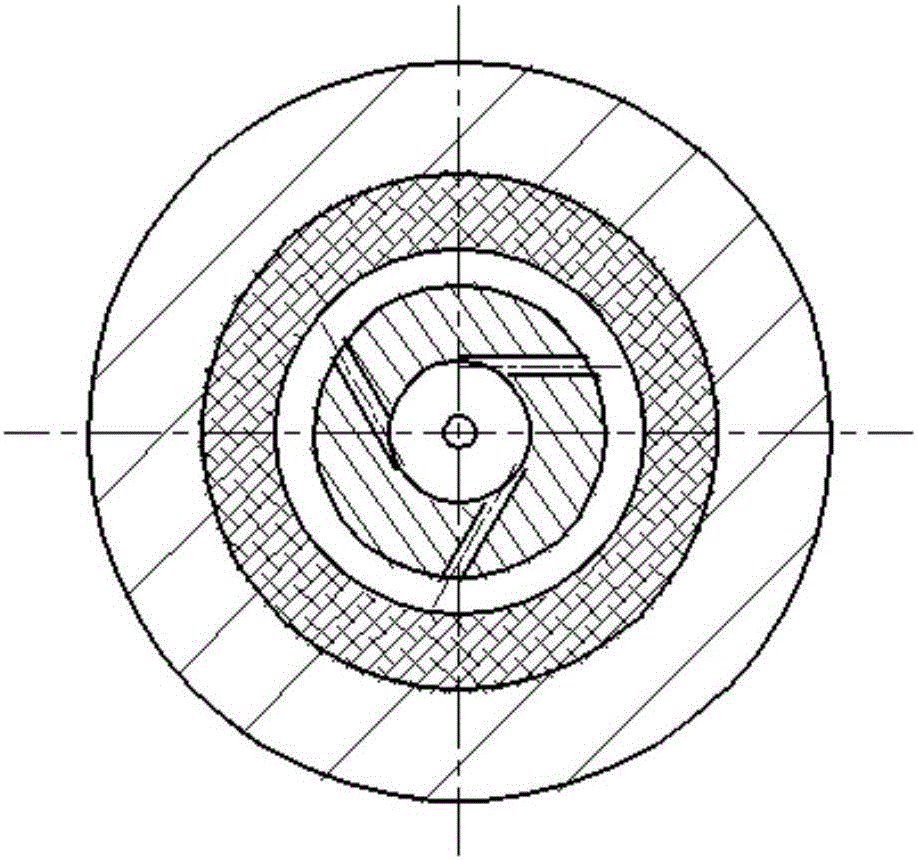

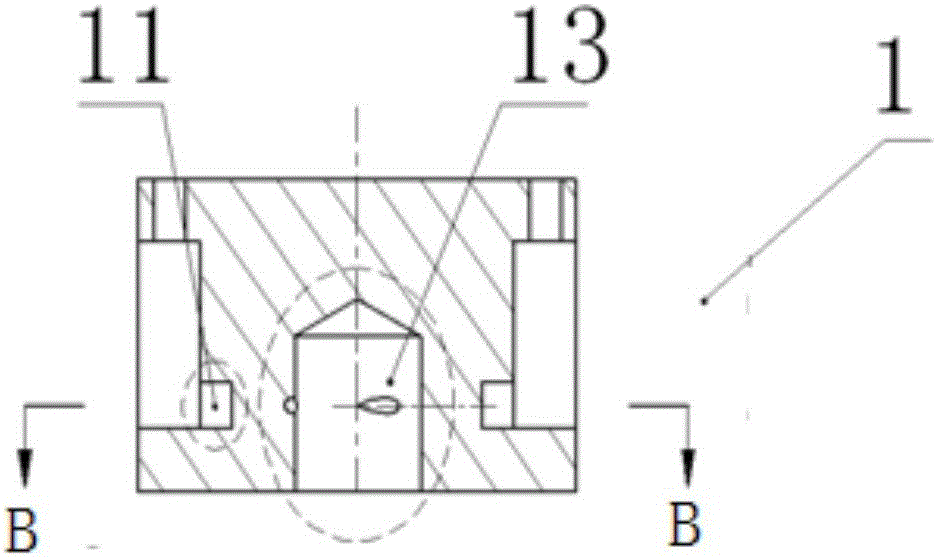

[0028] Such as Figure 1 to Figure 5 As shown, the anti-backfire nozzle for a rocket engine provided by the present invention is composed of a rotating core 1, an anti-backfire ring 2, a casing 3, and the like. The rotating core 1 is provided with a liquid accumulation cavity 11, a tangential hole 12 and a swirl chamber 13, such as image 3 , Figure 4 shown. The anti-tempering ring 2 is made of loose and porous material, installed between the rotating core 1 and the shell 3, and its inner and outer wal

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap