Apparatus and Integrated Process for Separating a Mixture of Carbon Dioxide and at Least One Other Gas and for Separating Air by Cryogenic Distillation

a technology of carbon dioxide and air separation, which is applied in the direction of separation processes, lighting and heating apparatus, liquefaction, etc., can solve the problems of real risk of introducing cosub>2 /sub>into the apparatus for separating air and clogging, and achieve the effect of lowering the temperature of unvaporized water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056]The invention shall be described in more detail by referring to the figures.

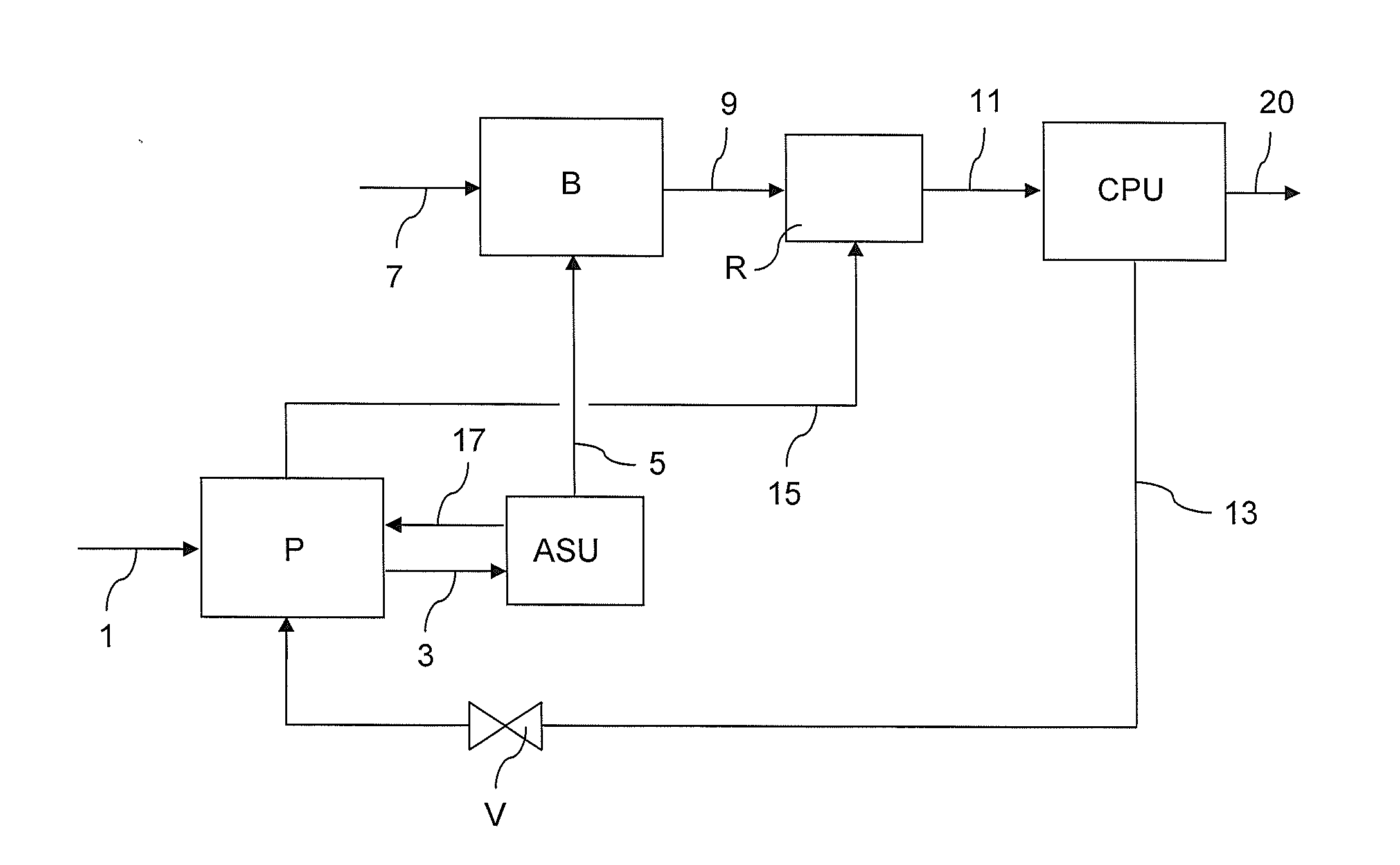

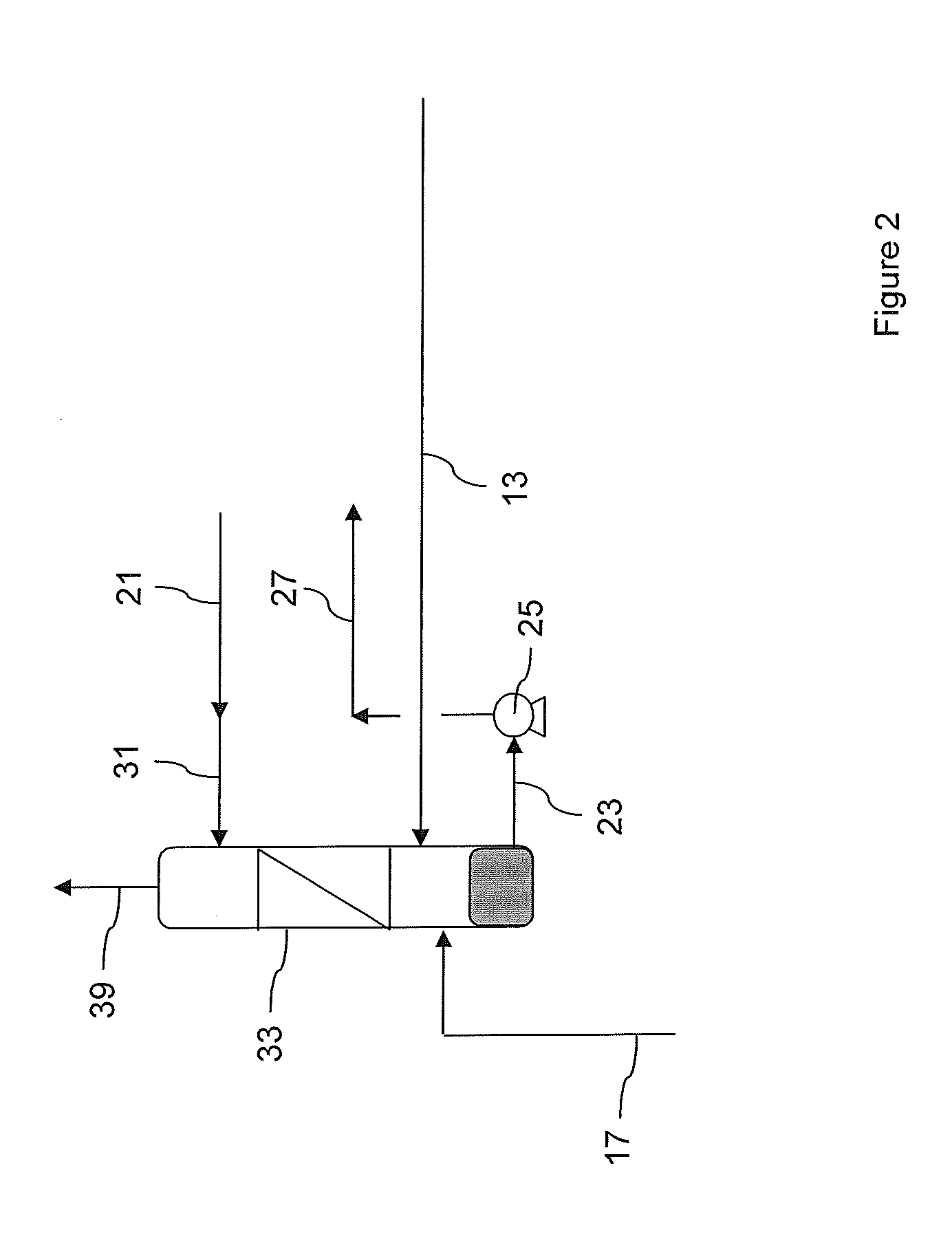

[0057]FIG. 1 shows an apparatus and an integrated process for separating a mixture of carbon dioxide and at least one other gas and for separating air by cryogenic distillation according to the invention. FIGS. 2 to 4 show the details of various water cooling towers used to cool the air upstream of the air separation by distillation in FIG. 1, according to the invention. In FIG. 1, a stream of air 1 is cooled in a pre-cooling unit P comprising an air scrubbing tower with water and a water cooling tower with nitrogen 17. This type of cooling is well known in the “Industrial Gas Handbook” by F. G. Kerry, page 112. The air 3 cooled in the pre-cooling unit P is sent to an apparatus for separating air ASU wherein it is purified in order to remove the carbon dioxide and the moisture, cooled and separated in a system of columns in order to produce oxygen 5 and nitrogen 17. The oxygen 5 is sent to an oxy-fuel com

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap