SCR denitration system with low SO2/SO3 conversion rate

A technology of SO3 and conversion rate, which is applied in the field of SCR denitrification system, can solve the problems of low conversion rate, achieve the effects of reducing conversion rate, improving service life, and convenient installation and implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

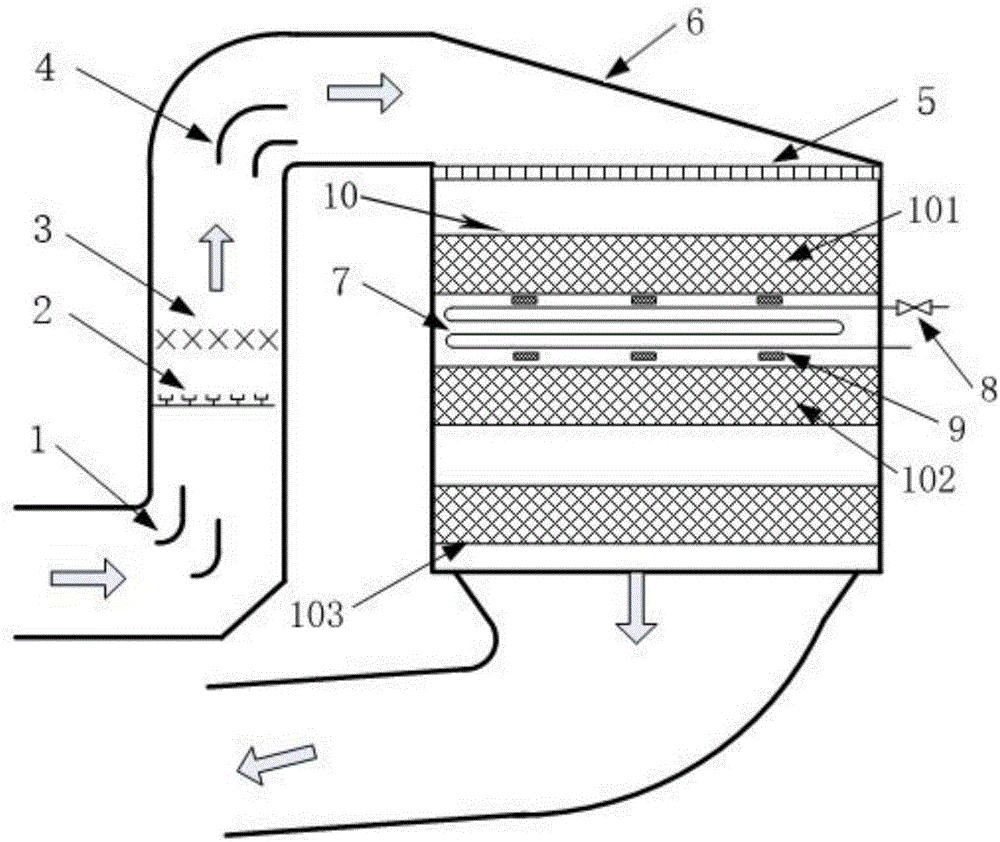

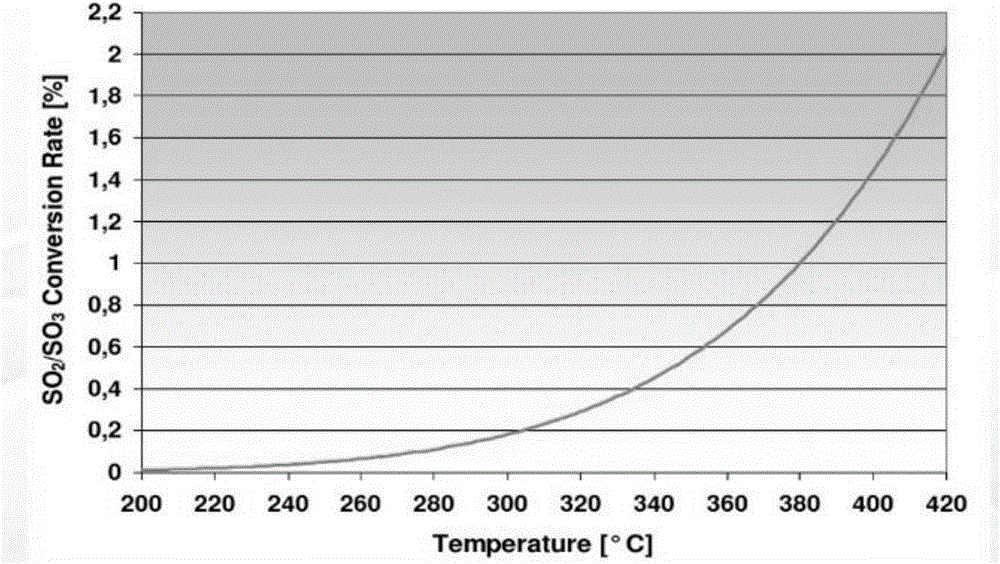

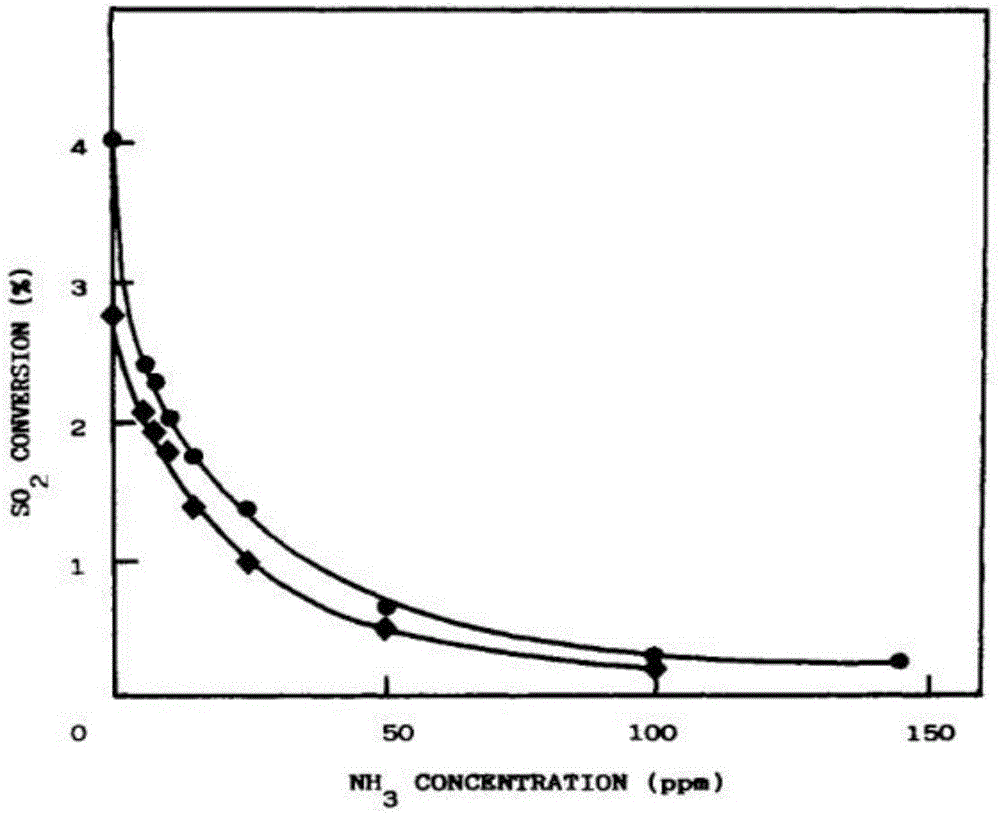

[0032] Embodiment 1: as figure 1 As shown, this embodiment includes an SCR reactor main body 12, an ammonia injection grid 2, and a catalyst layer 10. The catalyst layer 10 contains more than two layers of catalysts. A heat exchanger 7 is arranged between different catalysts in the catalyst layer 10. When the flue gas Before entering the catalyst layer of the lower layer through the upper catalyst layer, it first passes through the heat exchanger 7, the temperature is lowered, and the SO 2 / SO 3 conversion rate, thereby reducing the SO in the flue gas at the reactor outlet 3 amount.

Embodiment 2

[0033] Embodiment 2: as figure 1 As shown, in this embodiment, the catalyst layer 10 includes a first layer of catalyst 101, a second layer of catalyst 102, and a third layer of catalyst 103. The three layers of catalysts are arranged in sequence along the advancing direction of the flue gas, and the heat exchanger 7 is arranged on the first layer. Between the catalyst 101 and the second-layer catalyst 102, after the flue gas leaves the first-layer catalyst 101, it first passes through the heat exchanger 7, the temperature drops, and then enters the second-layer catalyst 102, reducing SO 2 / SO 3 conversion rate.

Embodiment 3

[0034] Embodiment 3: In this embodiment, a flue gas temperature sensing device 9 is provided above the heat exchanger 7 for real-time monitoring of the flue gas temperature. It is also possible to install temperature sensing devices 9 above and below the heat exchanger 7 to monitor the temperature of the flue gas before passing through the heat exchanger 7 and after passing through the heat exchanger 7, so as to achieve the purpose of precise control.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap