Method for operating an internal combustion engine and device for executing the method

a technology of internal combustion engine and method, which is applied in the direction of machines/engines, lighting and heating apparatus, separation processes, etc., can solve the problems of unpurified exhaust gas reaching the environment, reducing the performance capability of scr catalytic converter, etc., and achieves the effect of increasing the reliability during the operation of the internal combustion engine and being easily flammabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

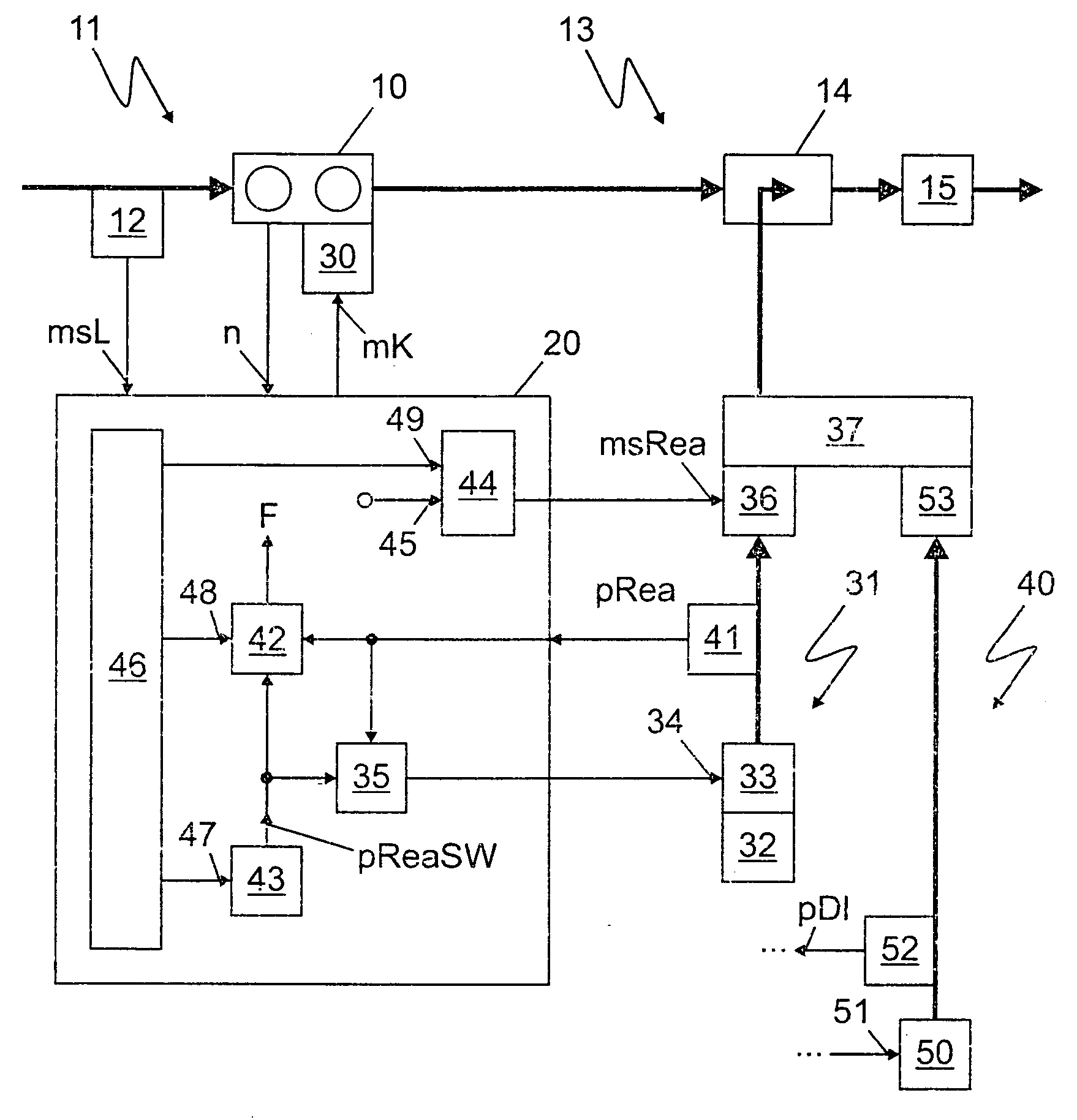

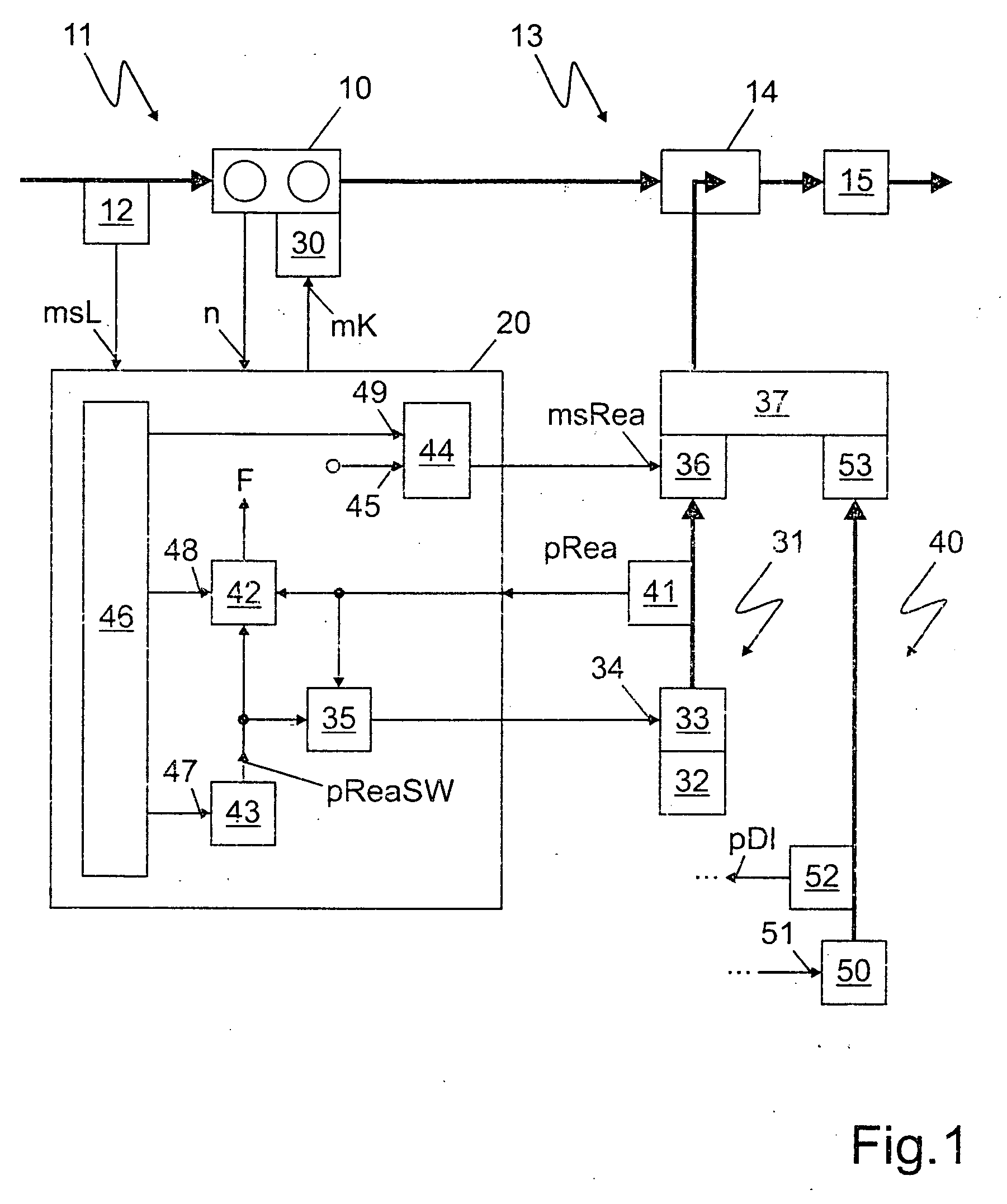

[0020]FIG. 1 shows an internal combustion engine 10, in whose intake area 11 an intake air detector 12 is positioned and in whose exhaust gas system 13 a reagent introduction device 14 and an exhaust gas treatment device 15 are positioned.

[0021] Intake air detector 12 outputs an air signal msL to a control unit 20 and internal combustion engine 10 outputs a speed n to control unit 20.

[0022] Control unit 20 provides a fuel signal mK to a fuel metering device 30.

[0023] In a reagent path 31, a reagent stored in a reagent tank 32 is brought to a predefined reagent setpoint pressure pReaSW by a reagent pump 33. Reagent pump 33 is activated by a reagent pump activation signal 34, which is provided by a reagent pump activator 35 positioned in control unit 20.

[0024] The reagent reaches a reagent dosing valve 36, which is connected to a mixing chamber 37. Furthermore, mixing chamber 37 is connected to a compressed air path 40. After mixing chamber 37, the reagent reaches reagent introductio

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Threshold limit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap