Method for adsorbing hydrogen fluoride and hydrogen chloride by using SBA-15 adsorbent

A technology of hydrogen fluoride and hydrogen chloride, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, can solve the problems of serious flying powder, large consumption of lime powder, and low removal efficiency, and achieves simple operation and simple equipment structure , good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

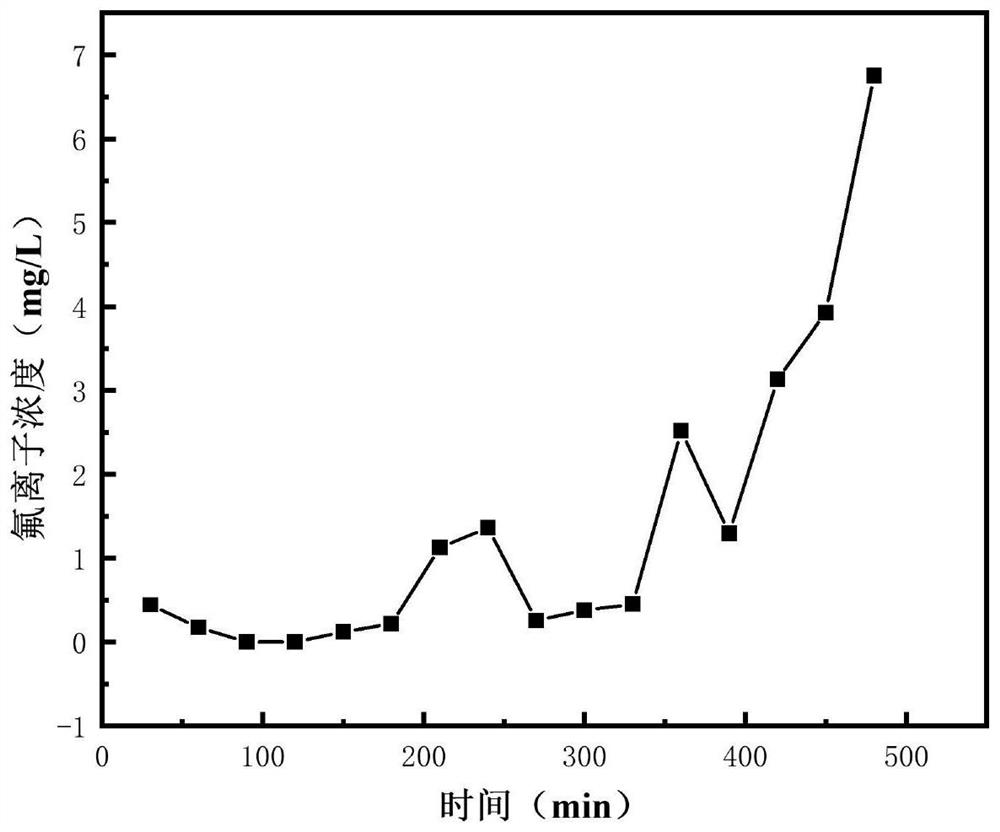

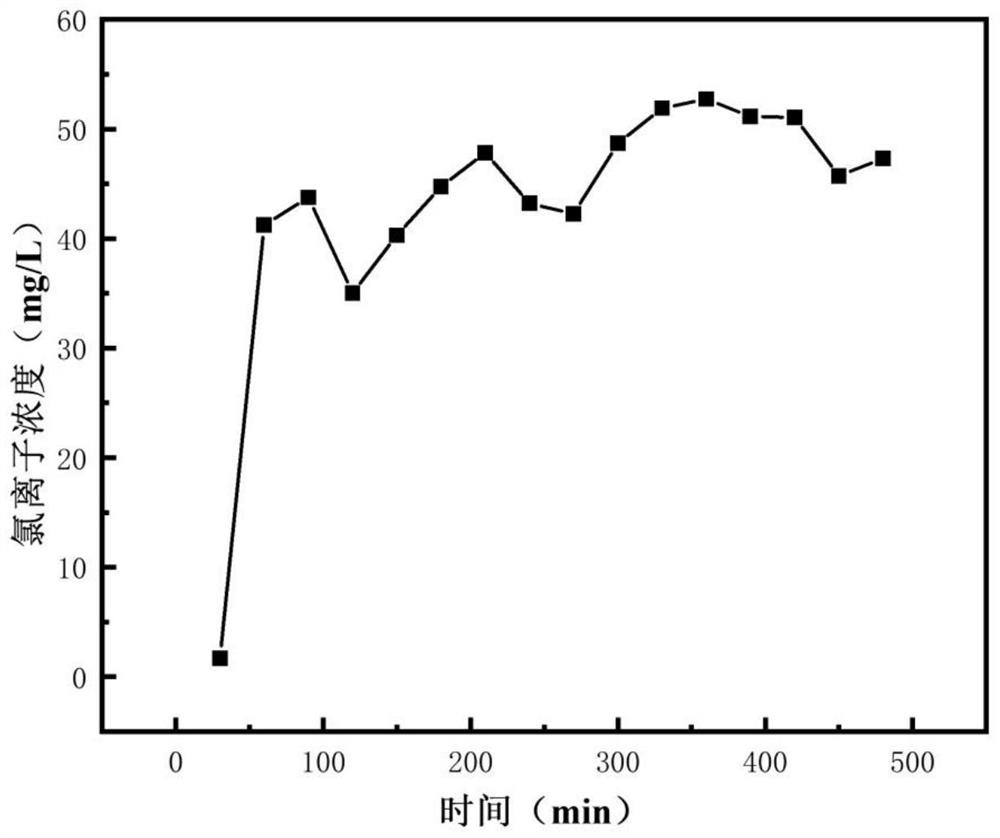

[0026] Pulverize SBA-15 to obtain 40-60 mesh SBA-15 particles, and load the SBA-15 particles on the surface of kaolin packing by roasting technology. and hydrogen chloride gas (the industrial waste gas containing hydrogen fluoride and hydrogen chloride obtained from a copper smelter, the concentrations of HF and HCl are 135ppm and 164ppm respectively), nitrogen is introduced into the packed tower, and the gas flow rate is 100mol / min, and the absorption liquid ( 2 mmol / L KOH solution) to absorb unreacted hydrogen fluoride and hydrogen chloride gas to obtain the adsorption curves of hydrogen fluoride and hydrogen chloride such as figure 1 , figure 2 shown.

[0027] Depend on figure 1 It can be seen that SBA-15 has a very good removal effect on fluoride ions. It penetrates in about 350min (the absorption efficiency reaches below 90%), and the removal rate of hydrogen fluoride can reach 99%.

[0028] Depend on figure 2 It can be seen that the removal effect of chloride ions

Embodiment 2

[0033] Pulverize SBA-15 to obtain 40-60 mesh SBA-15 particles, and load the SBA-15 particles on the surface of high-pressure graphite packing by roasting technology. Removal of hydrogen fluoride and hydrogen chloride gas (industrial waste gas containing hydrogen fluoride and hydrogen chloride obtained from a waste incineration plant, the concentrations of HF and HCl are 123ppm and 147ppm respectively), nitrogen gas is introduced into the packed tower, and the gas flow rate is 100mol / min, and reused The absorption liquid (2 mmol / L KOH solution) absorbs unreacted hydrogen fluoride and hydrogen chloride gas, that is, the adsorption of hydrogen fluoride and hydrogen chloride is completed.

Embodiment 3

[0035] Pulverize SBA-15 to obtain 40-60 mesh SBA-15 particles, and load the SBA-15 particles on the surface of borax filler by roasting technology. and hydrogen chloride gas (industrial waste gas containing hydrogen fluoride and hydrogen chloride obtained from a power plant, the concentrations of HF and HCl are 148ppm and 172ppm respectively), nitrogen is introduced into the packed tower, and the gas flow rate is 100mol / min, and the absorption liquid (2mmol / min) is reused. / L KOH solution) to absorb unreacted hydrogen fluoride and hydrogen chloride gas, that is, to complete the adsorption of hydrogen fluoride and hydrogen chloride.

[0036]The removal rate of each embodiment to hydrogen fluoride and hydrogen chloride is shown in Table 2, and the treatment cost comparison is shown in Table 3 (conventional treatment method is specifically: the lime powder is directly injected into the flue and reacts with the acid gas in the flue to generate solid products, so that it is remov

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap