Preparation method and application of high-surface-area high-dispersion manganese oxide-coated aluminum oxide fluorine-fixing agent

A high surface area, alumina technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as weak precursor binding force, and achieve easy control of process parameters, simple preparation process, and small grain size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

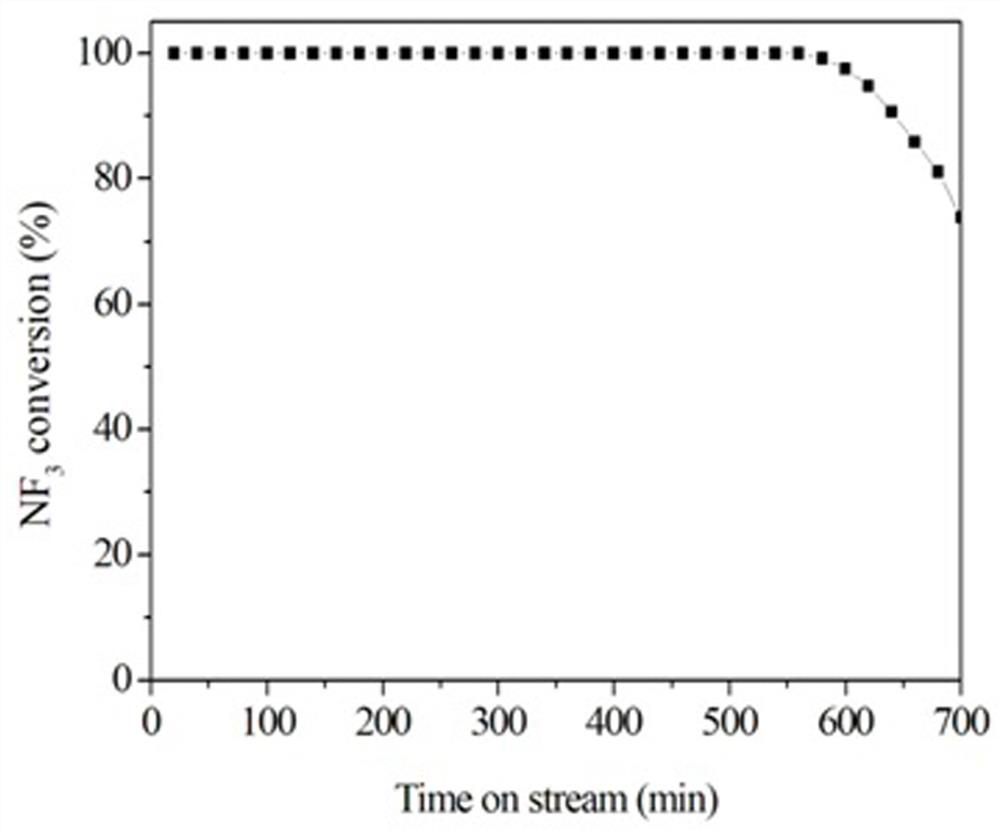

[0036] Embodiment 1: Al as fluorine-fixing agent or raw material of subsequent examples 2 O 3 Preparation and its NF 3 decomposition reaction.

[0037] Take 8 grams of glucose, dissolve it in 45 ml of double distilled water, make a solution, move it to a self-autoclave equipped with a 100-ml polytetrafluoroethylene liner, put the autoclave in an oven, and let the autoclave stand. , rise to 180 ℃ with the heating rate of 10 ℃ / min, constant temperature reaction 6 hours. The precipitate was washed alternately with double distilled water and ethanol. After drying at 80°C for 12 hours, carbon spheres were obtained.

[0038] Take 2.53 grams of aluminum nitrate and 1.62 grams of urea, dissolve them in 45 ml of double distilled water, add them to 1 gram of carbon spheres, stir and ultrasonically treat them for 10 minutes, and transfer them to an autoclave equipped with a 100-ml polytetrafluoroethylene liner. , autoclave is placed in baking oven, autoclave rotates, rises to 120 ℃ w

Embodiment 2

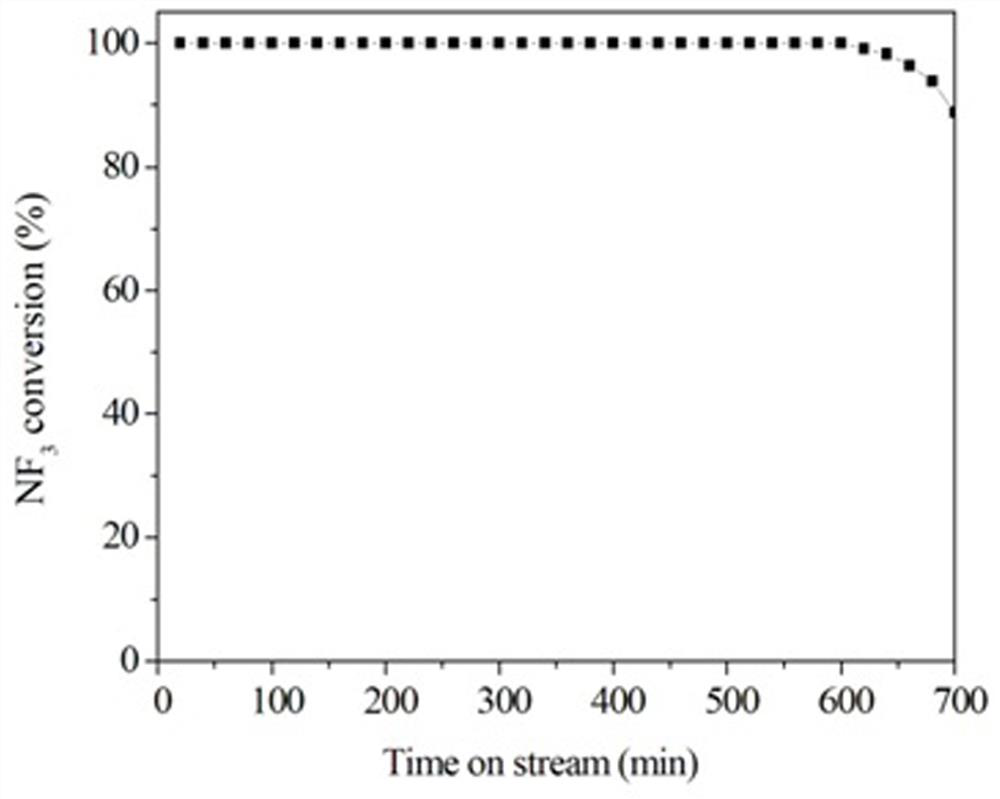

[0040] Embodiment 2: MnO as fluorine-fixing agent x Al coated 2 O 3 Preparation and NF 3 decomposition reaction.

[0041] Get 0.16 grams of manganese nitrate solution with a mass concentration of 50%, 0.13 grams of hexamethylenetetramine, dissolve in 45 milliliters of water, add to 0.5 grams of Al prepared by "Example 1" 2 O 3 In, stirring, ultrasonic treatment 10 minutes, move to be equipped with in the autoclave of 100 milliliters of polytetrafluoroethylene inner liner, the autoclave is placed in the baking oven, the autoclave rotates, with the heating rate of 10 ℃ / min Be raised to 120 DEG C, constant temperature reaction 4 hours, product is washed with double distilled water, and 80 DEG C of dryings are 12 hours. Rise to 600 DEG C with the heating rate of 2 DEG C / min in air, constant temperature roasting 4 hours, obtains MnO as fluorine-fixing agent x Al coated 2 O 3 (The mass of manganese accounts for 5% of the mass of alumina).

[0042] The measured specific sur

Embodiment 3

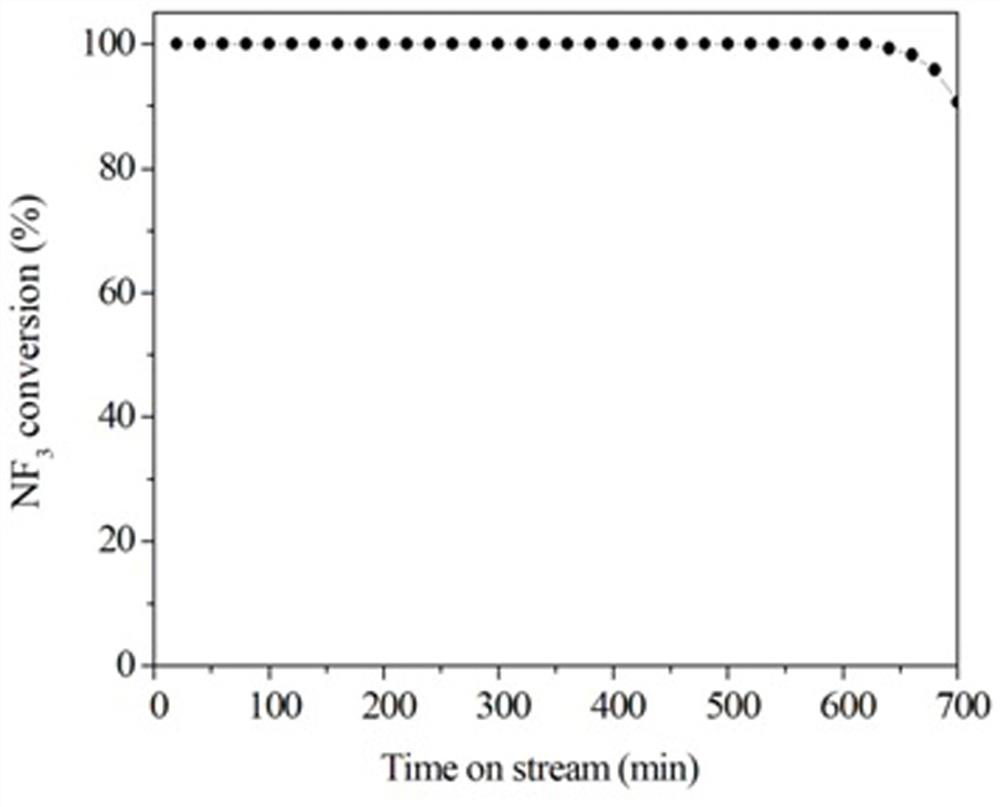

[0043] Embodiment 3: MnO as fluorine-fixing agent x Al coated 2 O 3 Preparation and NF 3 decomposition reaction.

[0044] Ramp up to 140°C at a ramp rate of 10°C / min, MnO x Al coated 2 O 3 Other preparation steps and parameters are the same as those in Example 2.

[0045] The measured specific surface area is 236.0m 2 / g. for NF 3 Anhydrous decomposition reaction, NF 3 For the decomposition percentage data see image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap