Water purifier water inlet joint with filtering function

A technology for water inlet joints and water purifiers, which is applied in the fields of filtration and separation, pipe/pipe joints/pipe fittings, chemical instruments and methods, etc., can solve the problems of increasing the use and maintenance costs of water purifiers, and the single function of water inlet joints, etc. Achieve the effect of reducing use and maintenance costs, compact structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

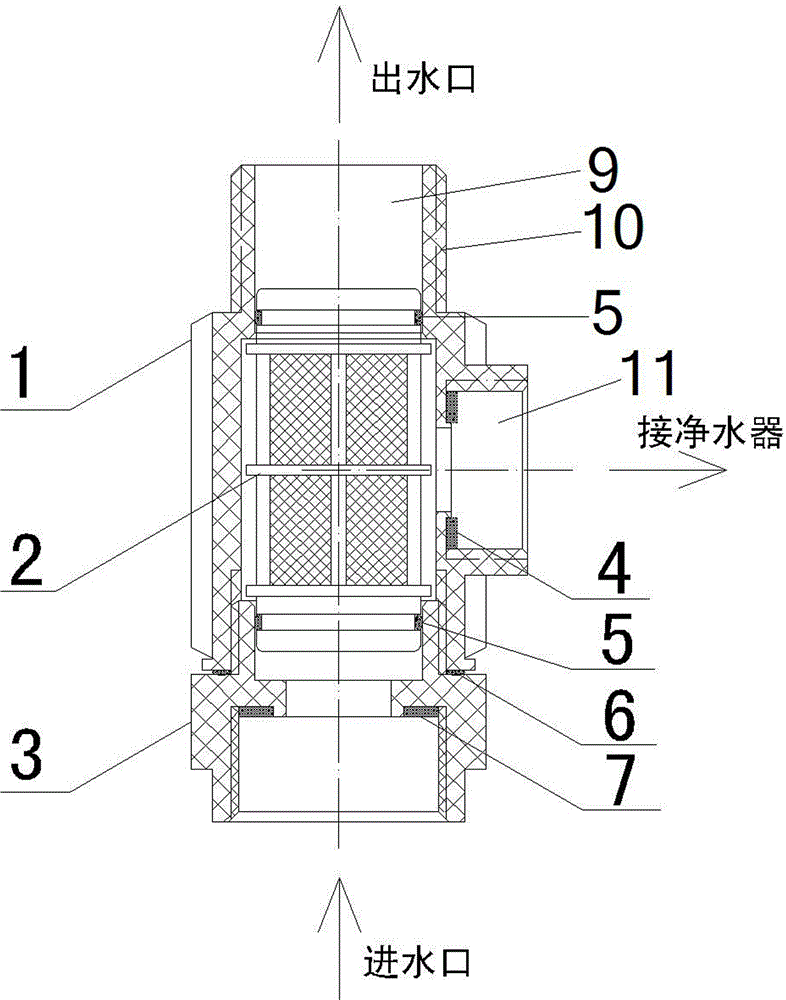

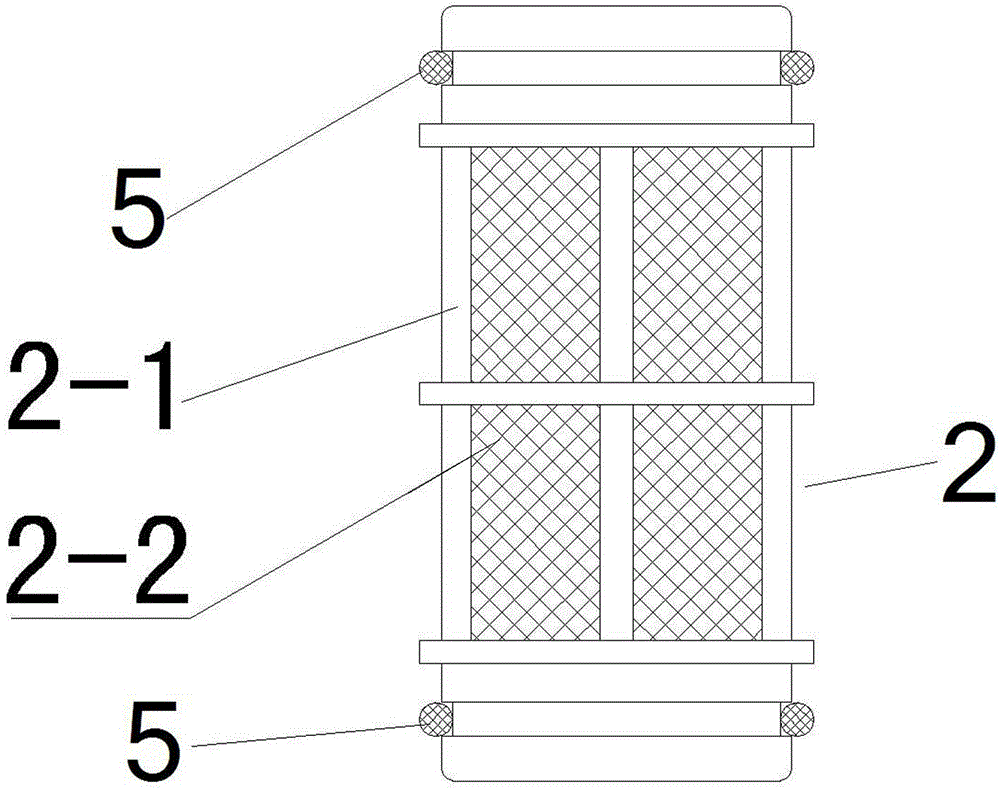

[0016] Refer to attached figure 1 , 2 , a water purifier water inlet joint with filtering function includes an upper joint body 1, a filter element (usually 304 stainless steel filter screen) 2, a lower joint body 3, a side water outlet gasket 4, a filter element sealing ring 5, and upper and lower body seals Pad 6, water inlet gasket 7. The upper joint body 1 is equipped with a filter element 2, the filter element 2 is equipped with a filter element sealing ring 5, the front end of the upper joint body 1 is provided with a water outlet 9, the side of the upper joint body 1 is provided with a side water outlet 11, and the side water outlet 11 is equipped with a side water outlet Gasket 4. The rear end of the upper joint body 1 is connected with the lower joint body 3, and the upper and lower body sealing gaskets 6 are installed at the junction of the upper joint body 1 and the lower joint body 3. The lower joint body 3 is provided with a water inlet 8, and the water inlet 8 is

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap