Belt edge

a belt edge and belt technology, applied in the field of belts, can solve the problems of affecting the shape of the belt, replacing more frequently, etc., and achieve the effect of reducing the tensile strength of the fused region so obtained and preventing the fraying of the edg

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054]In order that the invention may be more clearly understood an embodiment / embodiments thereof will now be described, by way of example only, with reference to the accompanying drawings, of which:

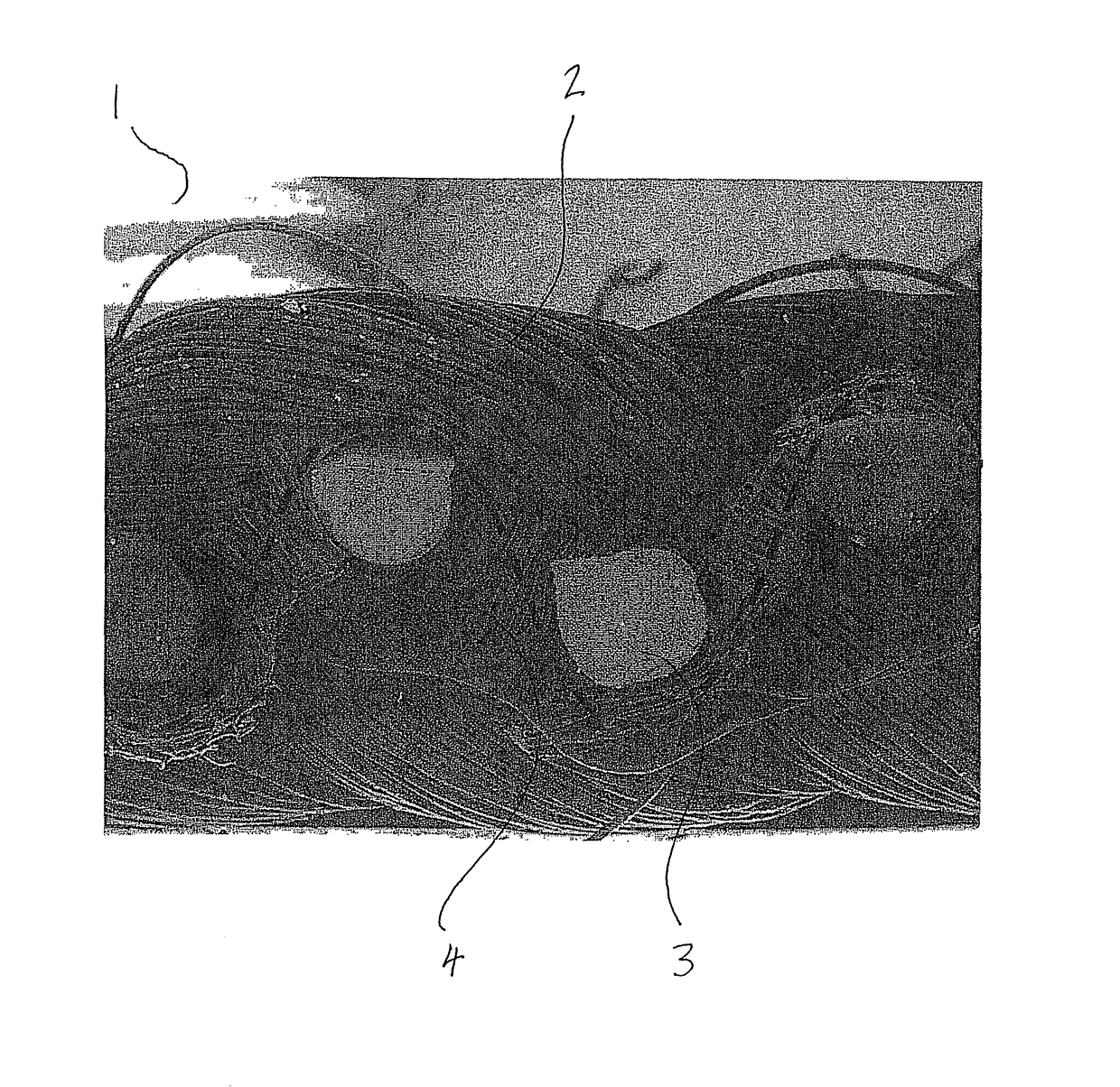

[0055]FIG. 1 shows a cross section of belt comprising warp yarns, weft yarns and a fused region formed from the warp yarn, the weft yarn and the yarn for fusing the warp and weft yarns.

[0056]The above embodiment is described by way of example only. Many variations are possible without departing from the scope of the invention.

[0057]FIG. 1 shows a cross section of a belt (1) comprising a plurality of interlocking warp yarns (2) and weft yarns (3). The warp yarns are longitudinal (i.e. they run in machine direction) and the weft yarns are woven through the warp yarns in a direction perpendicular to the machine direction. Further yarns (4) for fusing the warp yarns and the weft yarns are provided substantially parallel with the warp yarns (i.e. they also run in the machine direction) at eac

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap