Full-roadway drilling posture adjusting device for coal mine drilling rig

A technology of coal mine drilling rig and adjusting device, which is applied in the direction of support device, percussion drilling, rotary drilling, etc., can solve the problem of affecting the service life of the seal between the oil cylinder body, piston rod and piston, and affecting the normal use and safety of the drilling rig. Accidents and other problems, to achieve the effect of easy drilling rig height, good support rigidity, and avoid wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0035] The present invention will be further described below in conjunction with specific examples.

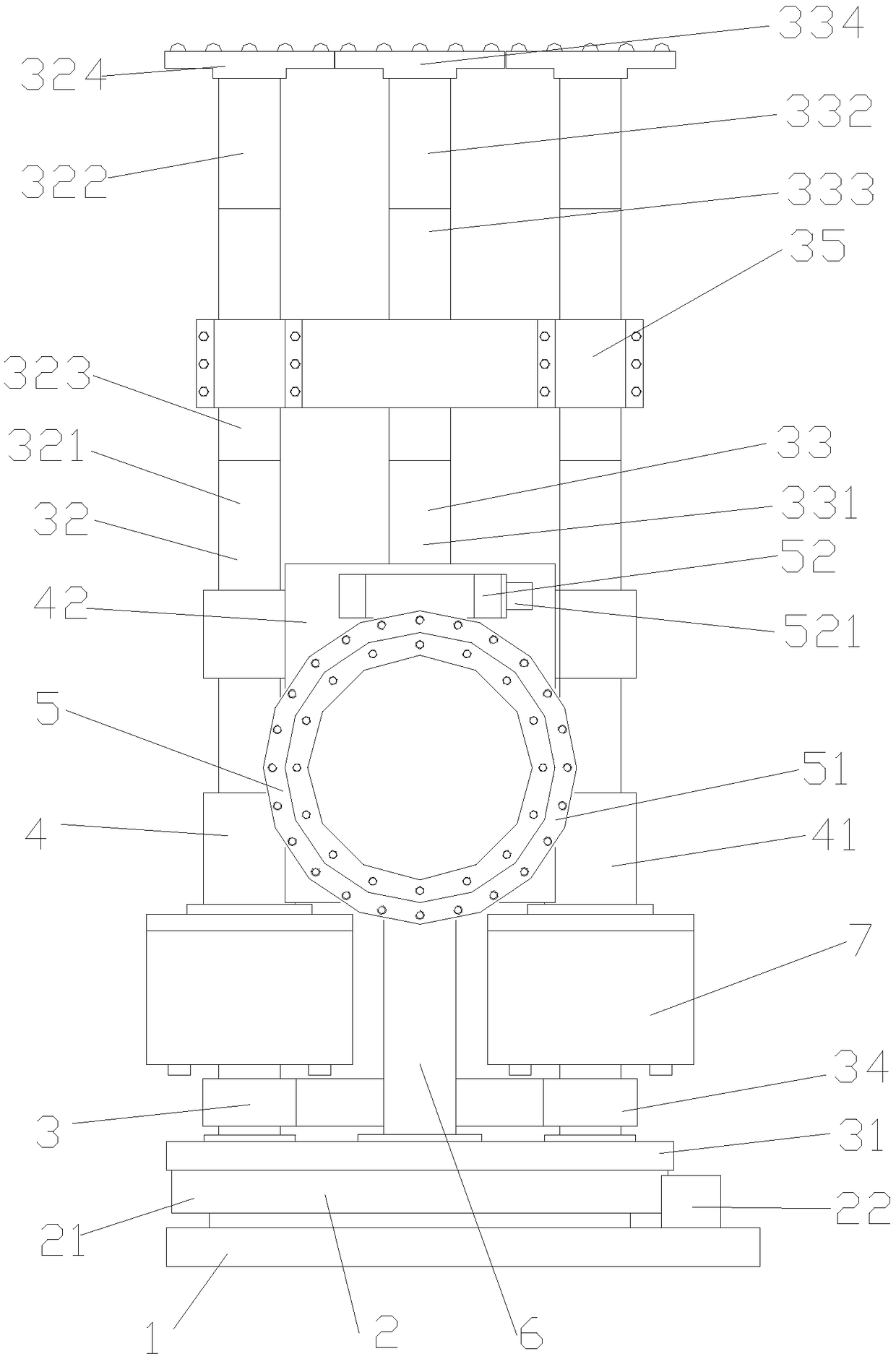

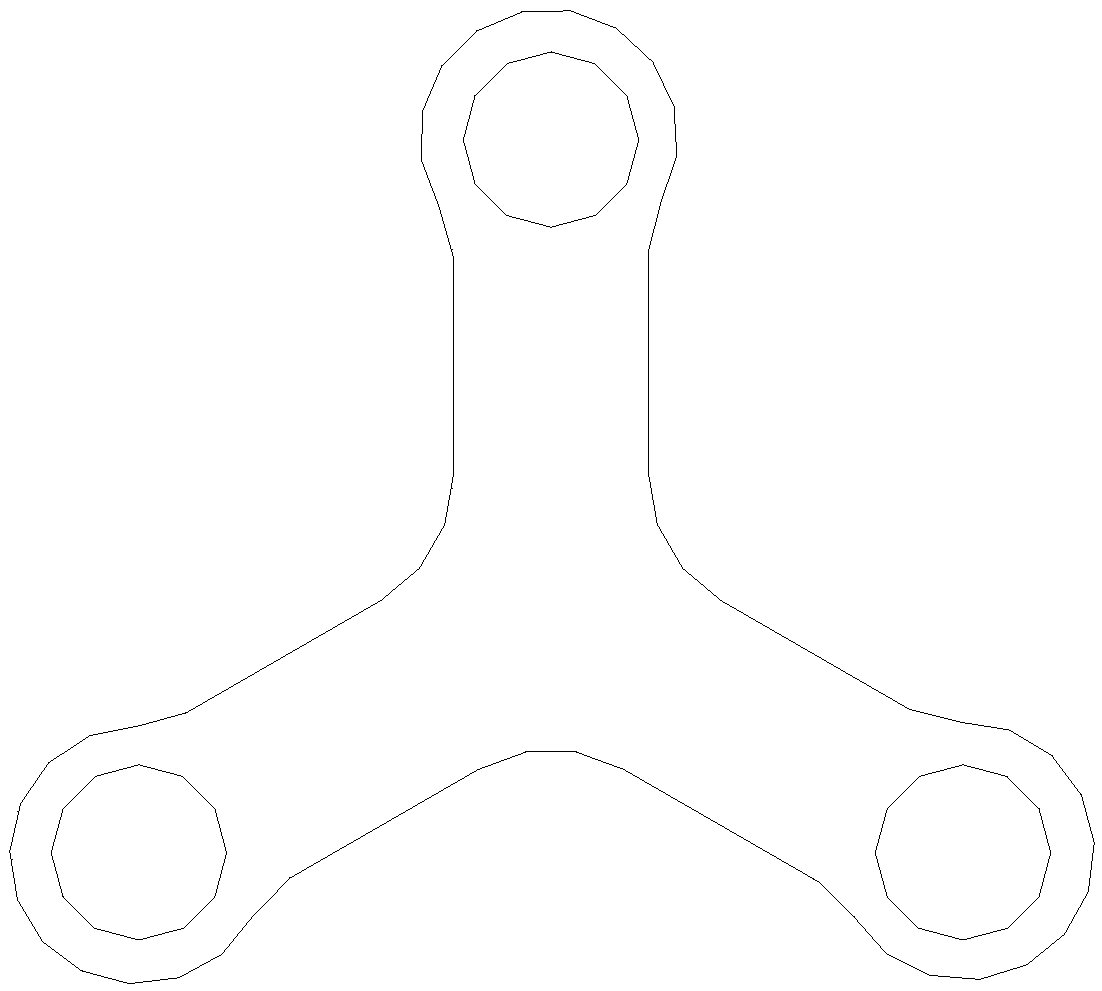

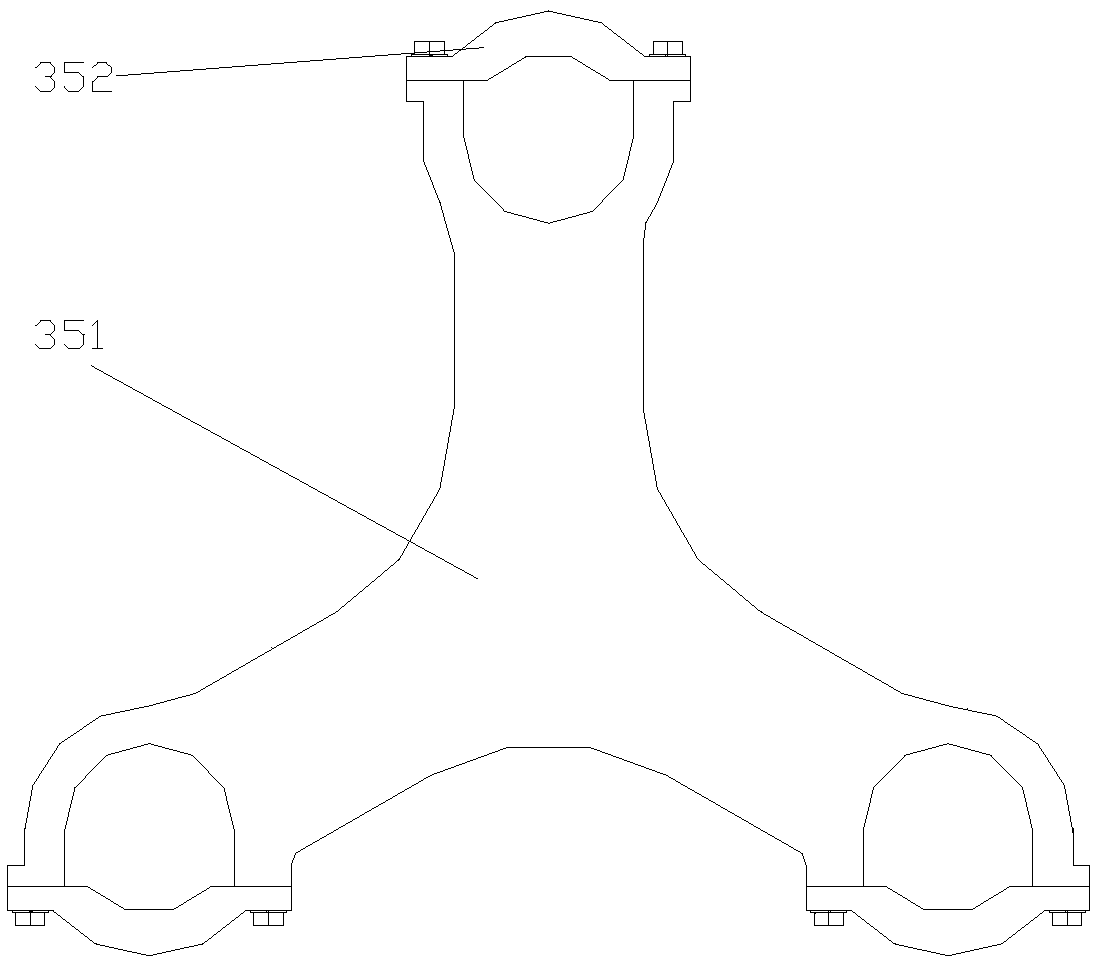

[0036] See attached Figures 1 to 8 As shown, the present invention also provides a full-tunnel drilling attitude adjustment device for a coal mine drilling rig, including an installation platform 1, a first turning device 2 arranged on the installation platform 1, an anchor frame 3 arranged on the first turning device 2, a sliding The fixed seat 4 for fixing the drilling machine arranged on the anchor frame 3, the second rotary device 5 arranged on the side of the fixed seat 4 for connecting the drilling machine and the thrust mechanism 6 for pushing the fixed seat 4 to move along the anchor frame 3 ;

[0037]The first slewing device 2 includes a first slewing bearing 21, a first drive mechanism 22 for driving the first slewing bearing 21 to rotate, and the first drive mechanism 22 includes a first drive housing 221 arranged on the installation platform 1, a rotatable set The

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap