Liquid treatment cartridge, set of such cartridges and method of manufacturing it

A liquid treatment, liquid technology, applied in the field of liquid treatment cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

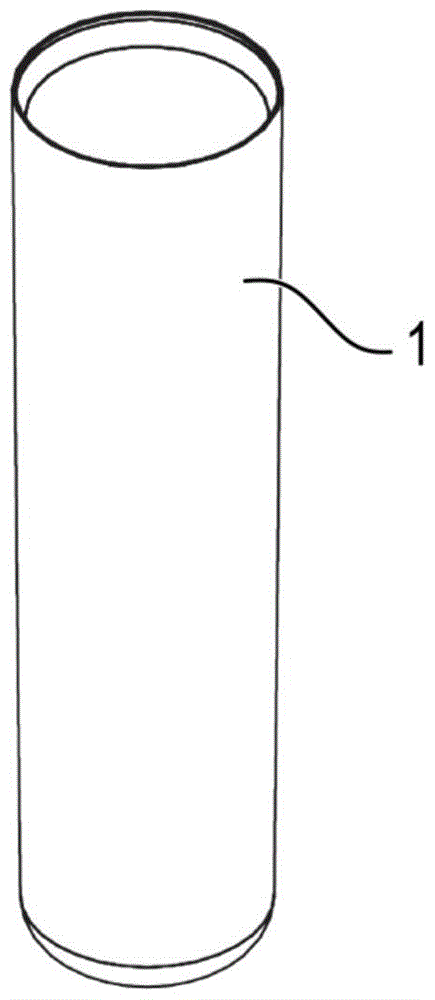

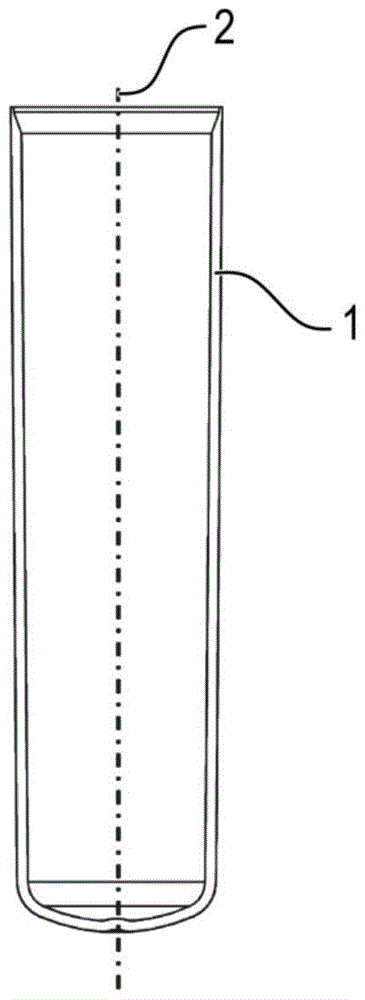

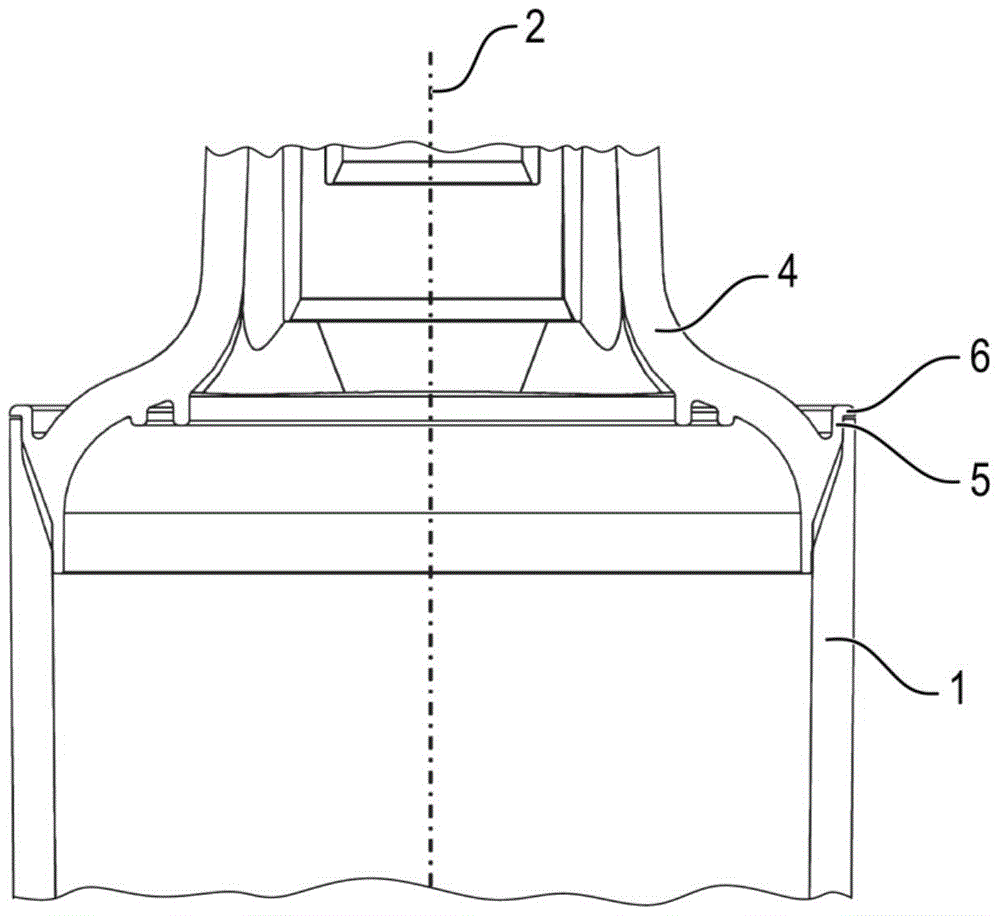

[0129] The liquid handling core as described below comprises a housing comprising a container in the form of a beaker-shaped housing part 1 ( Figure 1-3 , Figure 22 , Figure 36-39 ). The beaker-shaped housing part 1 is elongated in shape. The central axis 2 (in this example the longitudinal axis 2 ( figure 2 , image 3 )) form the reference axis. The beaker-shaped housing part 1 is closed at one axial end and open at the opposite axial end. The beaker-shaped housing part 1 is substantially cylindrical along most of its length. The closed axial end is rounded to withstand the pressure of the liquid in the beaker-shaped housing part 1 during use. The beaker-shaped housing part 1 can be made of metal such as aluminum or plastic such as polypropylene. The open end of the beaker-shaped housing part 1 is closed by and irreversibly bonded to the hat-shaped housing part.

[0130] The first hat-shaped housing part 3 ( Figure 3-21 ) comprises a main body 4, which can be obta

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap