Automatic water-stopping filter element holder

A filter seat and water stop technology, applied in the field of water treatment, can solve problems such as furniture damage, loss, and valves that cannot stop water, so as to improve the replacement efficiency and improve the use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

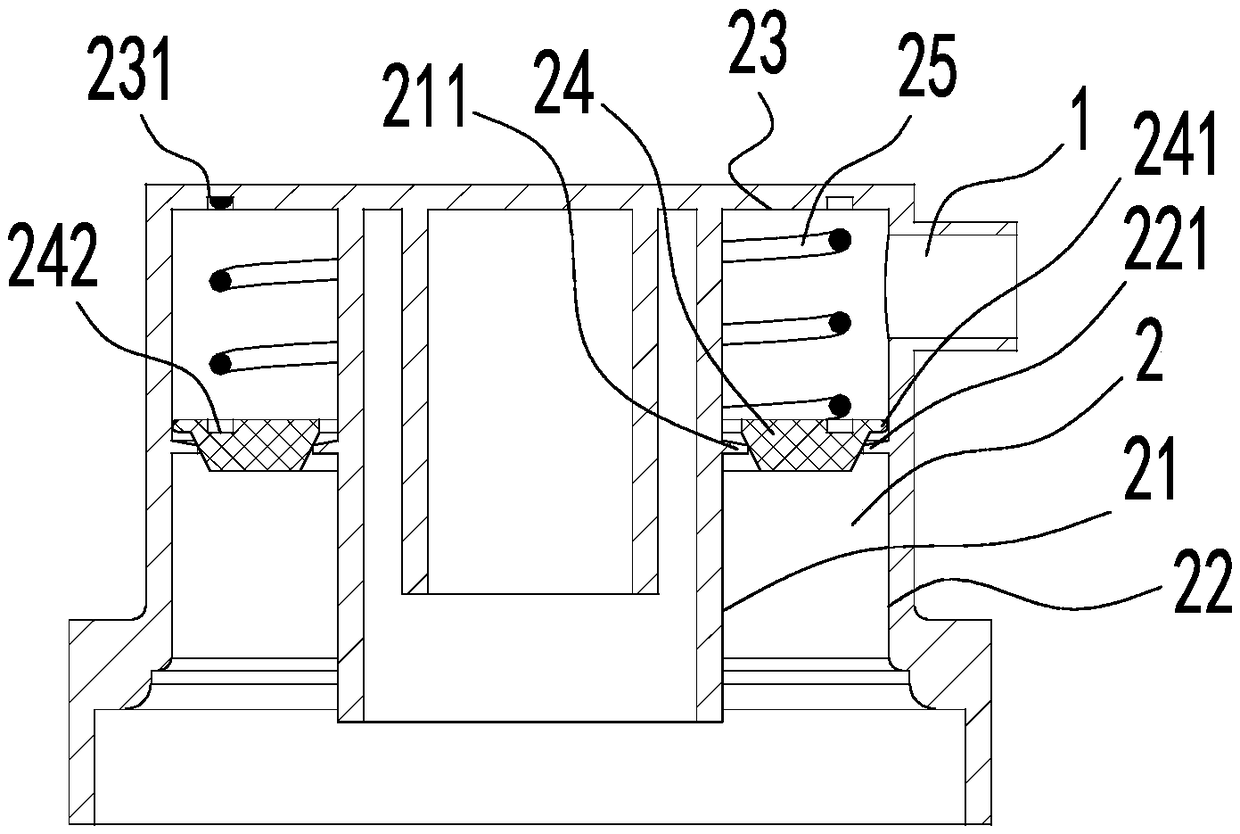

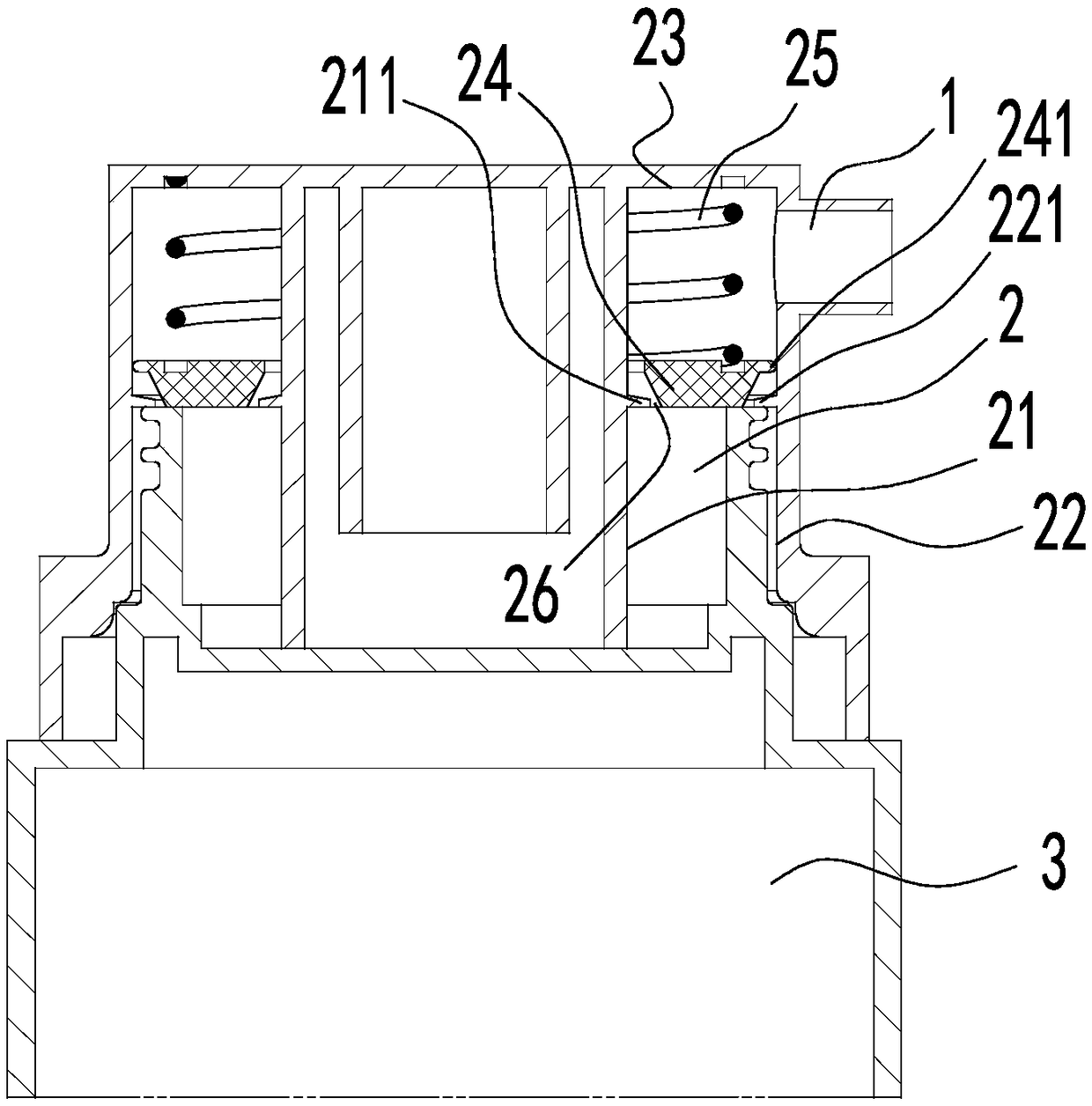

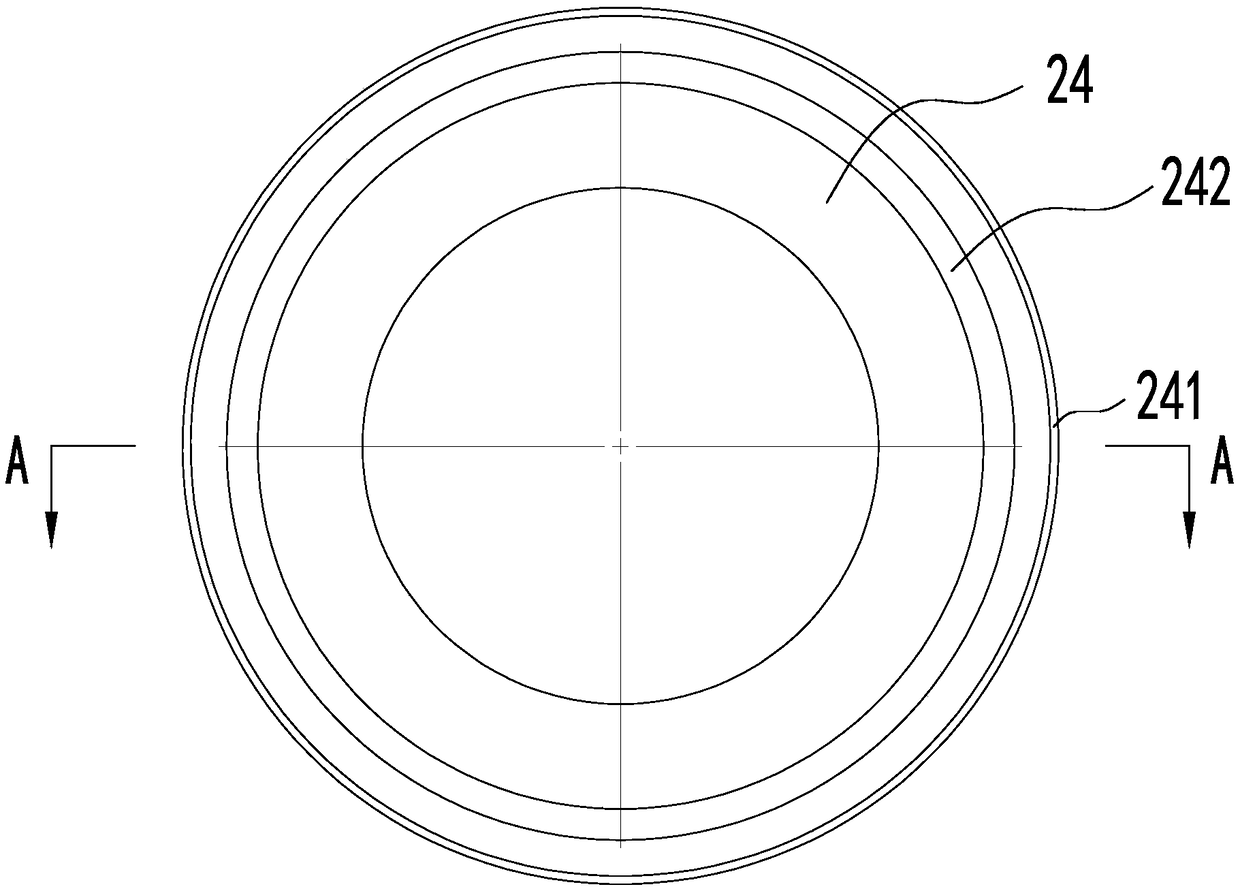

[0020] see figure 1 , 3 And 4, the automatic water-stop filter cartridge seat of the present invention includes a water inlet 1 and a connecting chamber 2 communicated with the filter core body 3, and the connecting chamber 2 includes a first inner wall 21, a second inner wall 22 and a third inner wall 23, and the The first inner wall 21 and the second inner wall 22 are respectively provided with a first protruding position 211 and a second protruding position 221 along the circumference. A flange 241 is arranged on the circumference, and the flange 241 and the second inner wall 22 are always in close contact with the second inner wall 22 during the movement of the sealing ring 24. One end of the elastic connector 25 is abutted against the third inner wall 23, The other end of the elastic connector 25 abuts against the sealing ring 24. When the filter core body 3 is rotated away from the filter seat, under the elastic force of the elastic connector 25, the sealing ring 24 is loc

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap