Preparation method of officinal nano-zinc oxide

A nano-zinc oxide and zinc hydroxide technology, applied in the field of medicine and chemical industry, can solve the problem of high organic solvent residue, and achieve the effects of reducing energy consumption, low reaction temperature and low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 10kg of zinc hydroxide was powdered and ground, and 10kg of fatty acid glycerides and 60L of deionized water were added to the autoclave. Stir the reaction at 110°C and 20MPa for 2 hours. After the reaction is over, the obtained solution is ultrasonically washed for 30 minutes and the supernatant liquid is poured off. The obtained filter cake is washed with deionized water and ultrasonically for 30 minutes to remove the supernatant liquid. The obtained solid is ultrasonically washed with ethanol for 30 minutes and then used for nanofiltration Membrane filtration, the filter cake was then ultrasonically washed with deionized water for 30 min and filtered with a nanofiltration membrane. The solid obtained in the above steps was dried at 40° C. for 3 hours under a reduced pressure of 0.08 Mpa to obtain nano zinc oxide.

[0025] The particle size range of the obtained nanometer zinc oxide is 3-60 nanometers, and the product purity is 99.95%.

Embodiment 2

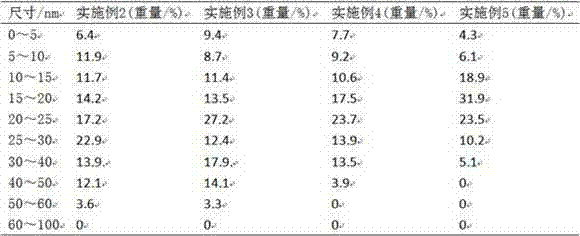

[0027] 15kg of zinc hydroxide was powdered and ground, and 30kg of fatty acid glycerides and 80L of deionized water were added to the autoclave. Stir and react at 130°C and 30MPa for 2 hours. After the reaction is over, the obtained solution is ultrasonically washed for 30 minutes and then the supernatant is poured off. The obtained filter cake is washed with deionized water and ultrasonically for 30 minutes to remove the supernatant. The obtained solid is ultrasonically washed with ethanol for 30 minutes and filtered through a nanofiltration membrane. 1. The filter cake was ultrasonically washed with deionized water for 30 min and filtered through a nanofiltration membrane. The solid obtained in the above steps was dried at 40° C. for 3 hours under a reduced pressure of 0.08 Mpa to obtain nano zinc oxide.

[0028] The particle size range of the obtained nanometer zinc oxide is 3-60 nanometers, and the product purity is 99.92%.

Embodiment 3

[0030] 10kg of zinc hydroxide was powdered and ground, and 25kg of fatty acid glycerides and 50L of deionized water were added to the autoclave. Stir and react at 140°C and 40MPa for 2 hours. After the reaction, the obtained solution is ultrasonically washed for 30 minutes, and then the supernatant is poured out. The obtained filter cake is washed with deionized water and ultrasonically for 30 minutes to remove the supernatant. The obtained solid is ultrasonically washed with ethanol for 30 minutes and filtered with a nanofiltration membrane. 1. The filter cake was ultrasonically washed with deionized water for 30 min and filtered through a nanofiltration membrane. The solid obtained in the above steps was dried at 40° C. for 3 hours under a reduced pressure of 0.08 Mpa to obtain nano zinc oxide.

[0031] The particle size range of the obtained nanometer zinc oxide is 3-60 nanometers, and the product purity is 99.91%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap