Wafer clamp and cleaning method thereof

A wafer jig, a jig technology, which is applied to cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc. Effective cleaning, low manufacturing cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

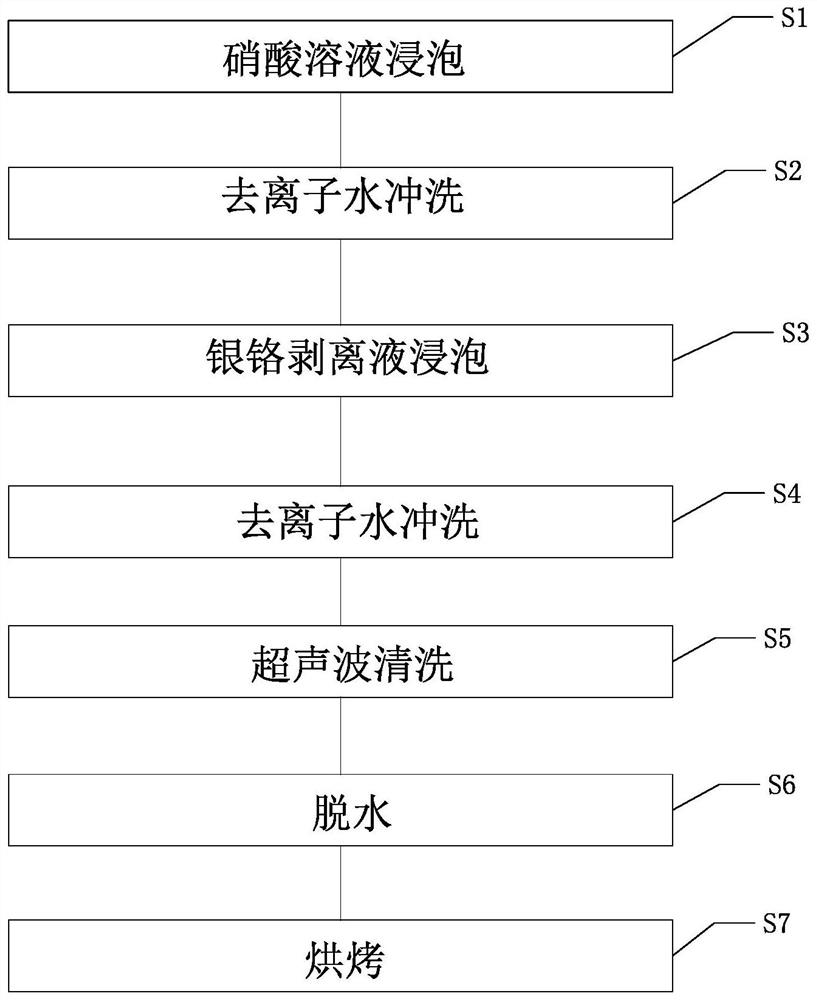

[0029] Such as Figure 1 to Figure 7 As shown, the cleaning method of a kind of wafer holder provided by the present invention comprises the following steps:

[0030] S1. Soaking in nitric acid solution: put the jig into the soaking pool, pour in nitric acid solution for soaking.

[0031] In step S1, the height of the nitric acid solution poured into the immersion tank is greater than the height of the jig, and the jig is immersed in the nitric acid solution for 15 minutes for a single immersion time, and silver flakes on the surface are removed.

[0032] S2. Rinse with deionized water: rinse the nitric acid solution on the fixture soaked in step S1 with deionized water, and at the same time rinse off attached physical impurities.

[0033] The flushing time in step S2 is 300 seconds, and the resistance of the deionized water used for flushing should b

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap