Power plant thermal instrument dust removal device

A technology for thermal instruments and dust removal devices, which is applied in chemical instruments and methods, cleaning methods and utensils, and cleaning methods using gas flow, etc. and other problems, to achieve good cleaning and improve the effect of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

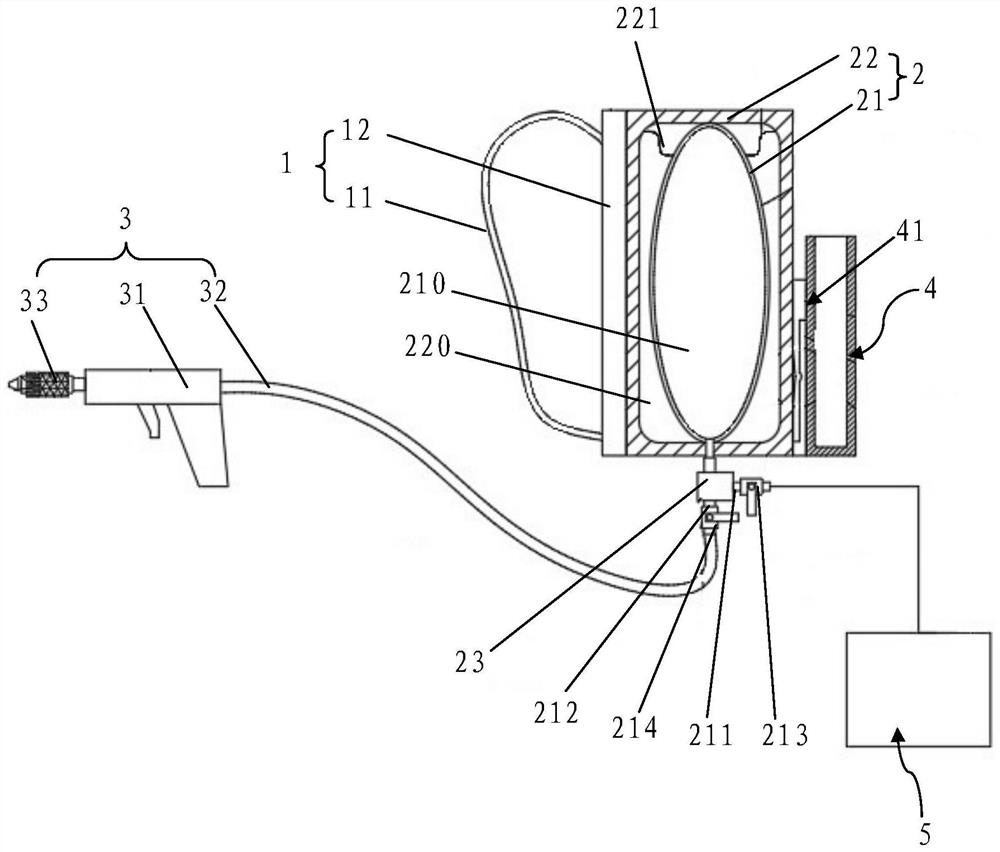

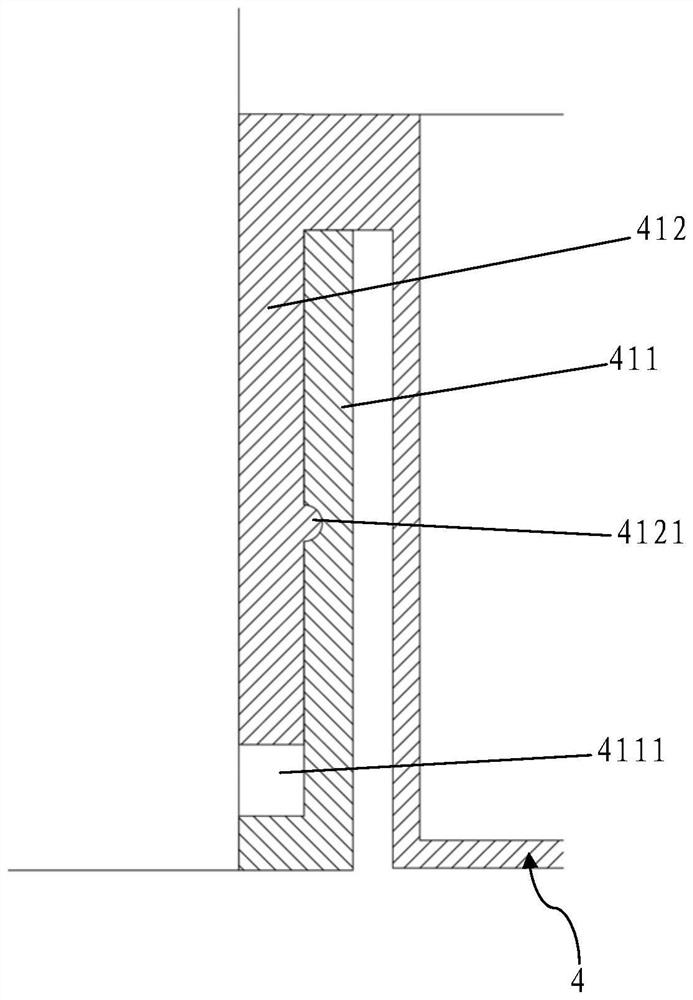

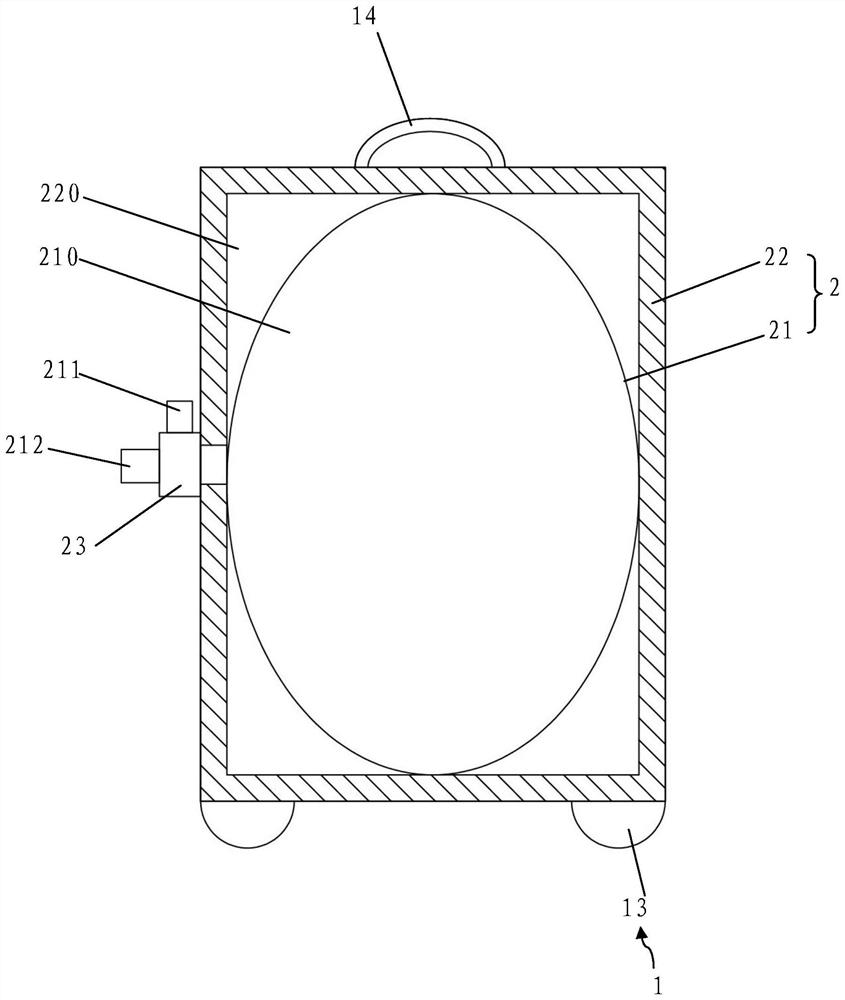

[0034] The specific embodiments of the present application will be further described below with reference to the accompanying drawings.

[0035] It is easy to understand that, according to the technical solutions of the present application, without changing the essential spirit of the present application, those of ordinary skill in the art can interchange various structural modes and implementation modes. Therefore, the following specific embodiments and accompanying drawings are only exemplary descriptions of the technical solutions of the present application, and should not be regarded as the whole of the present application or as limitations or restrictions on the technical solutions of the application.

[0036] Orientation terms such as up, down, left, right, front, rear, front, back, top, bottom, etc. mentioned or possibly mentioned in this specification are defined relative to the configurations shown in the respective drawings, which are It is a relative concept, so it may

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap