Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12 results about "Organic layer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

There is the organic layer, which is insoluble in water and initially contains all of your compounds that you will eventually separate. The organic layer also contains a solvent (CH2Cl2 or ether) that is insoluble in water. So the organic layer= Compounds we're trying to separate + insoluble solvent.

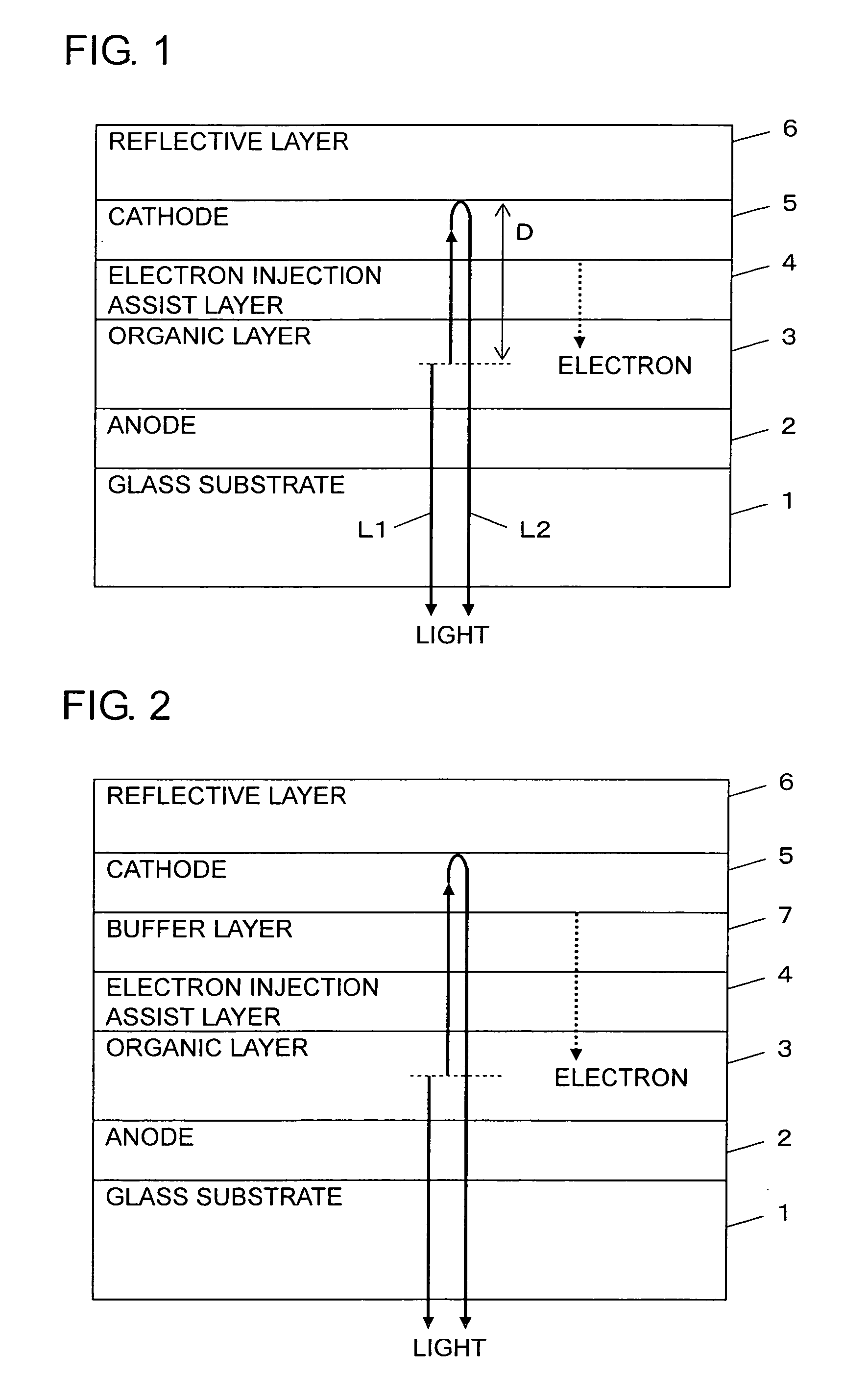

Organic electroluminescent device

ActiveUS20120319095A1Improve stabilityImprove featuresOrganic chemistrySolid-state devicesArylDopant

Owner:NIPPON STEEL CHEMICAL CO LTD

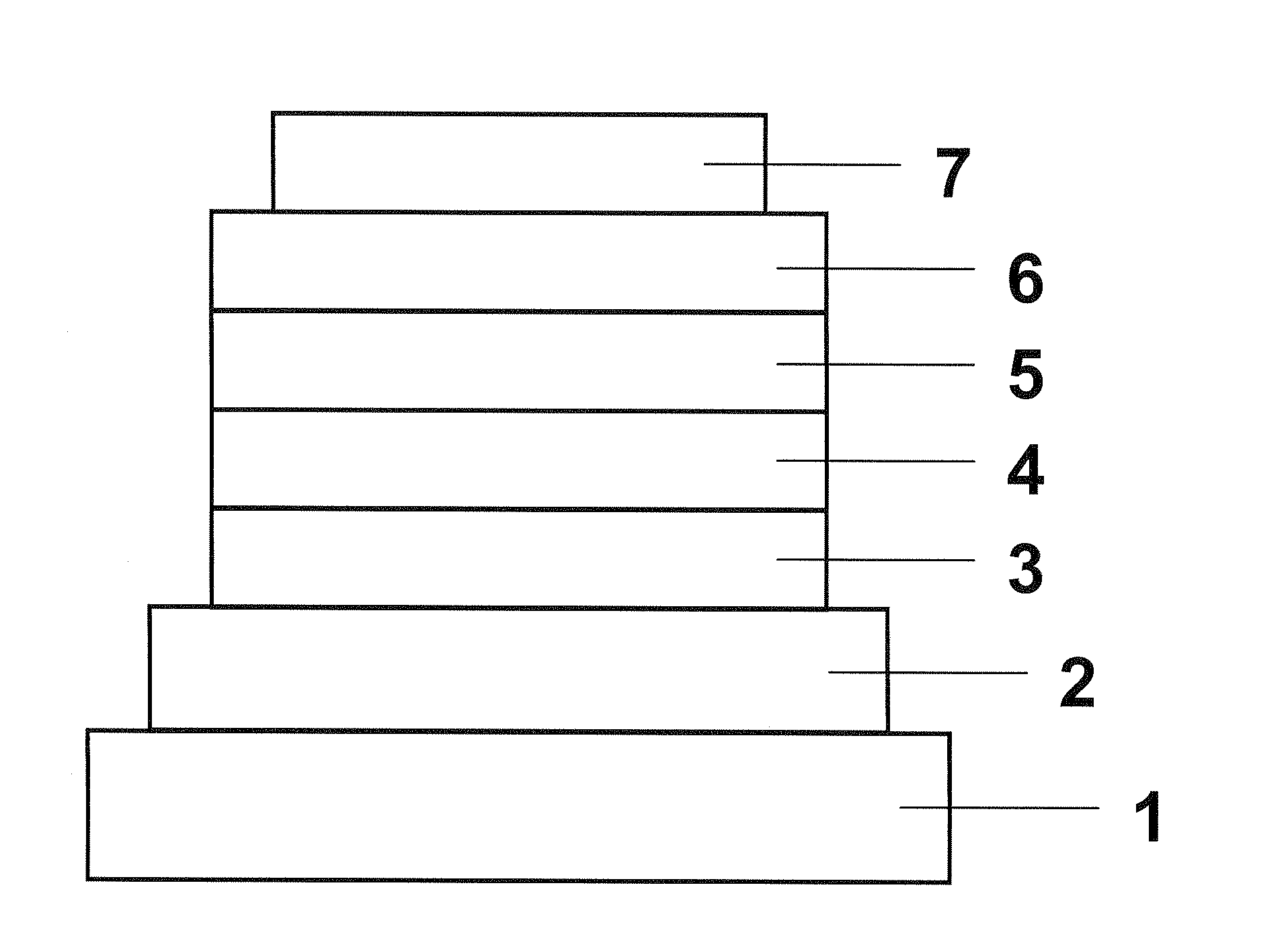

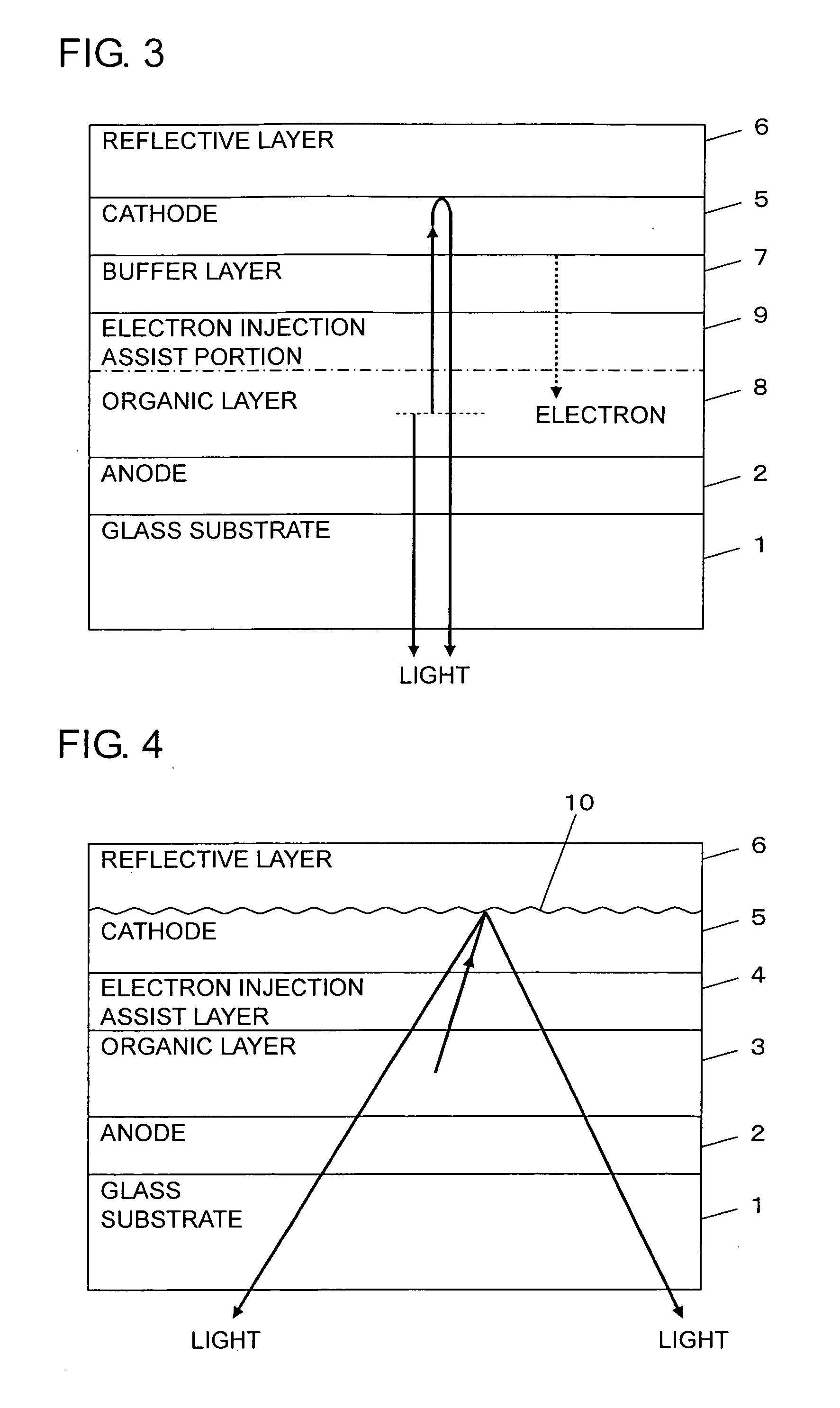

Organic EL device

InactiveUS20060108580A1Efficient solutionSolid-state devicesElectroluminescent light sourcesOrganic layerOptoelectronics

Owner:TOYOTA IND CORP

Dry toner, processes for the production thereof, and the use thereof

InactiveUS7955772B2High resolutionFlat surfaceDevelopersElectrographic process apparatusSilanesZirconate

Owner:ECKART GMBH & CO KG

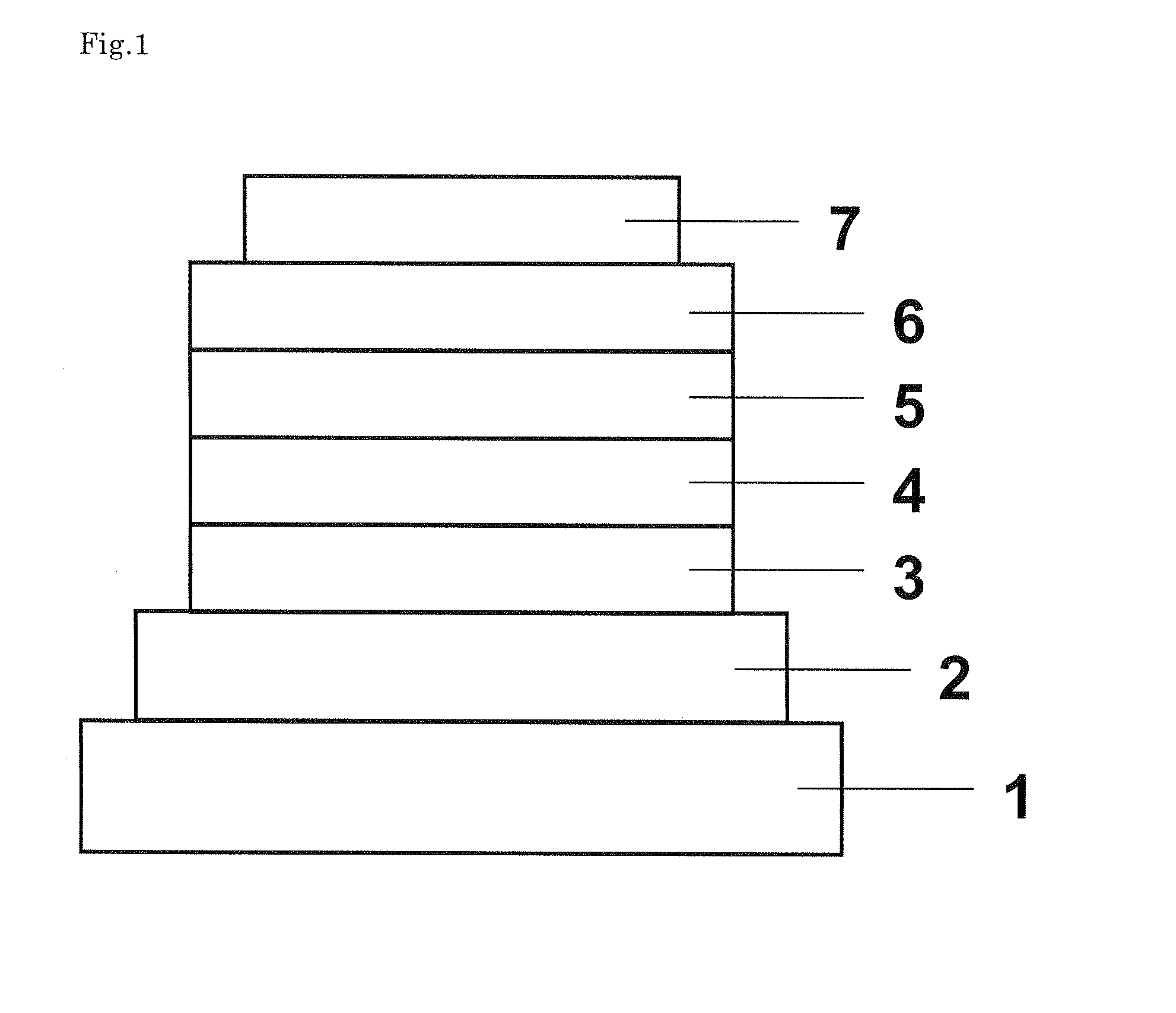

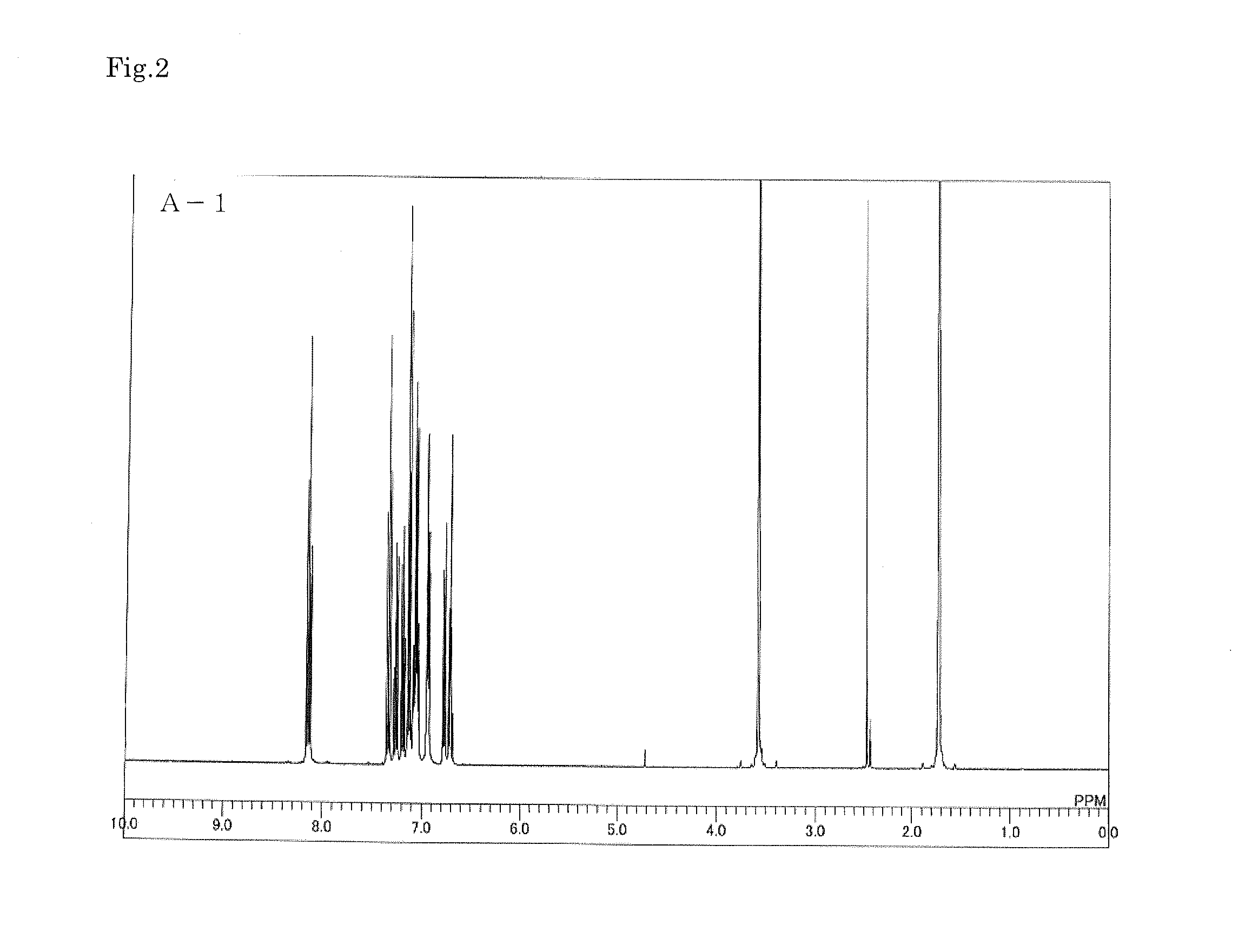

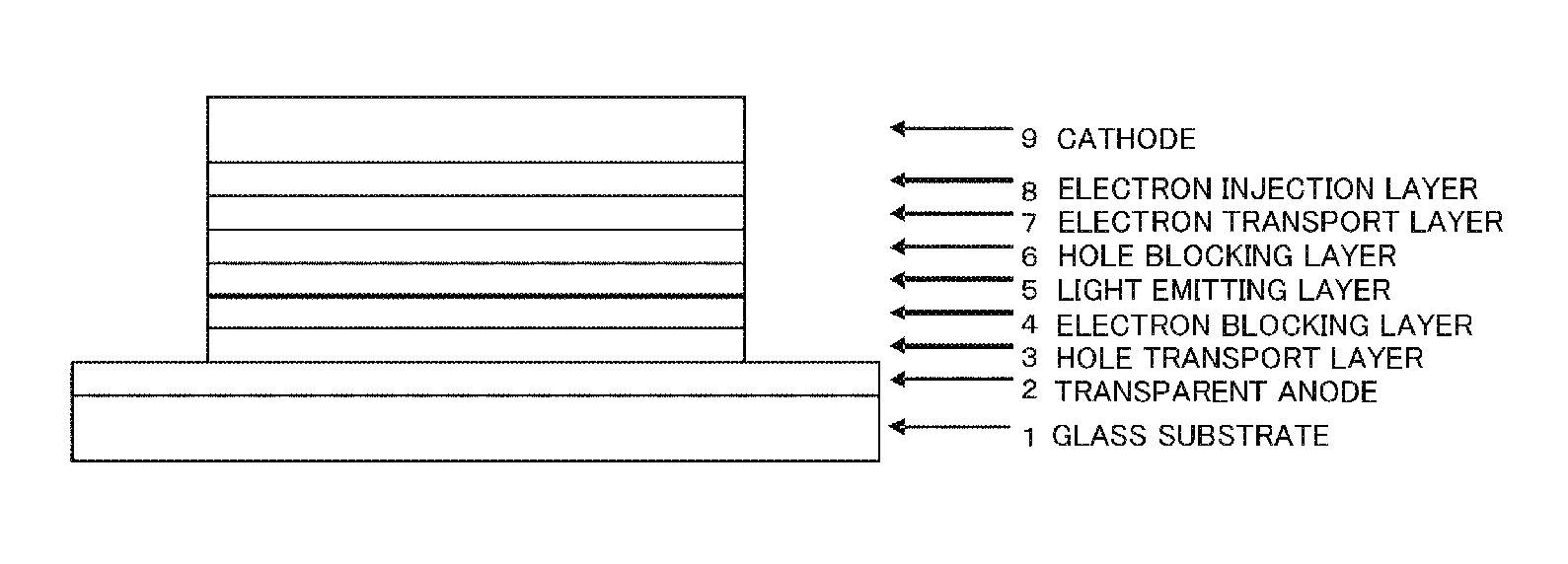

Compound having triphenylene ring structure, and organic electroluminescent device

InactiveUS20160204352A1Stable thin-film stateImprove heat resistanceGroup 4/14 element organic compoundsGroup 5/15 element organic compoundsPhotoluminescenceChemical compound

Owner:HODOGAYA KAGAKU IND +1

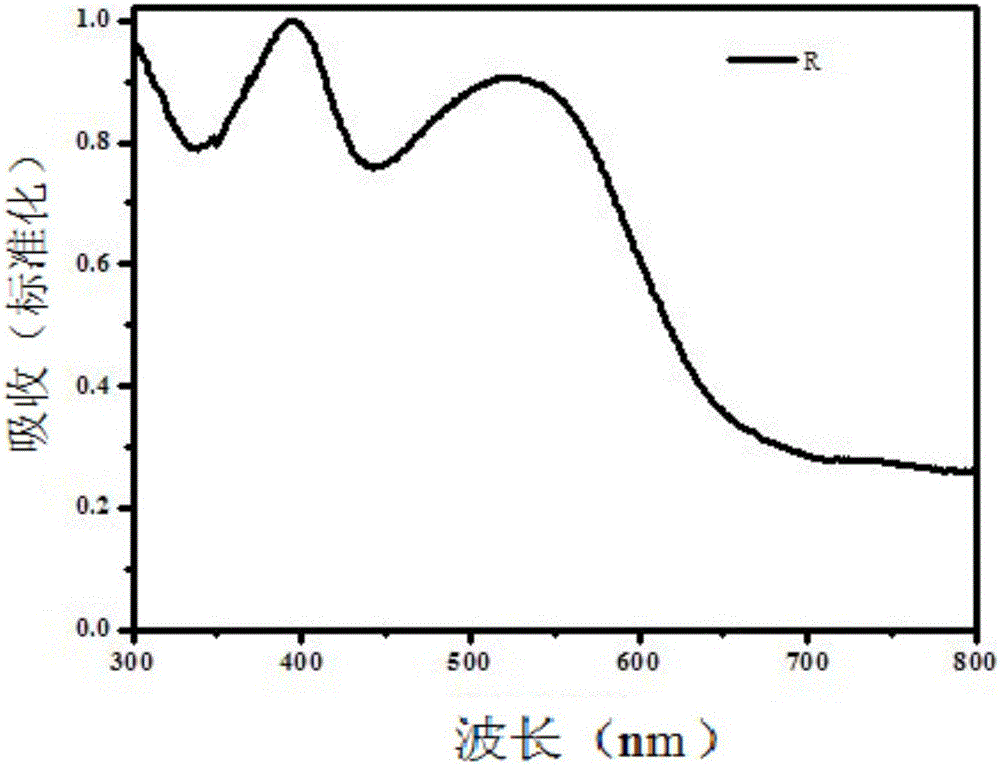

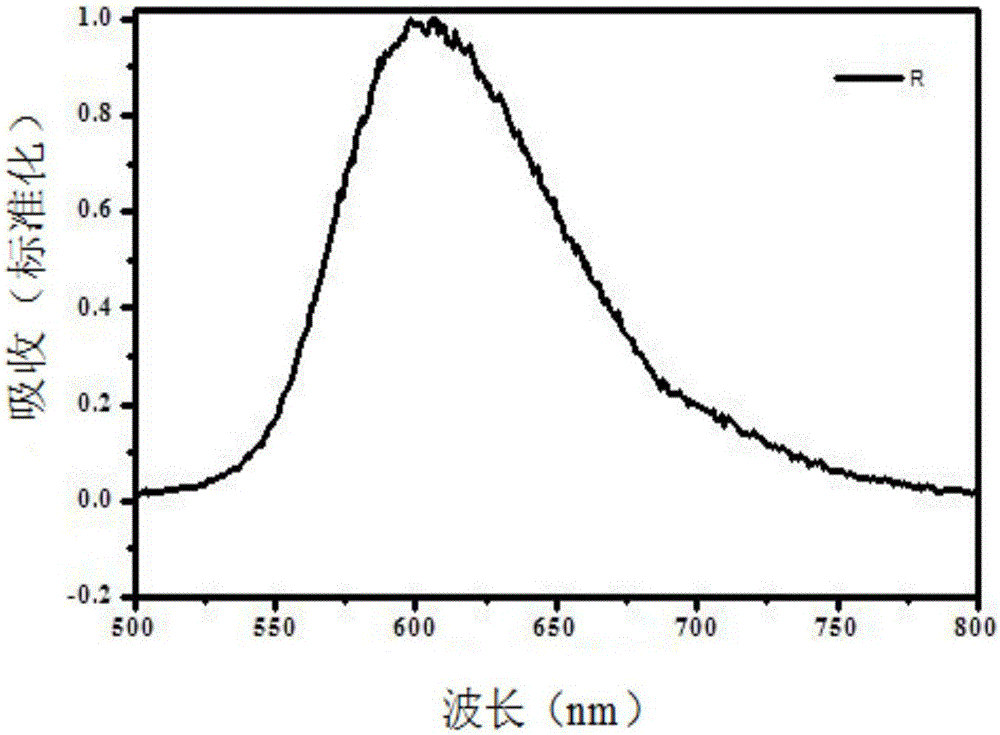

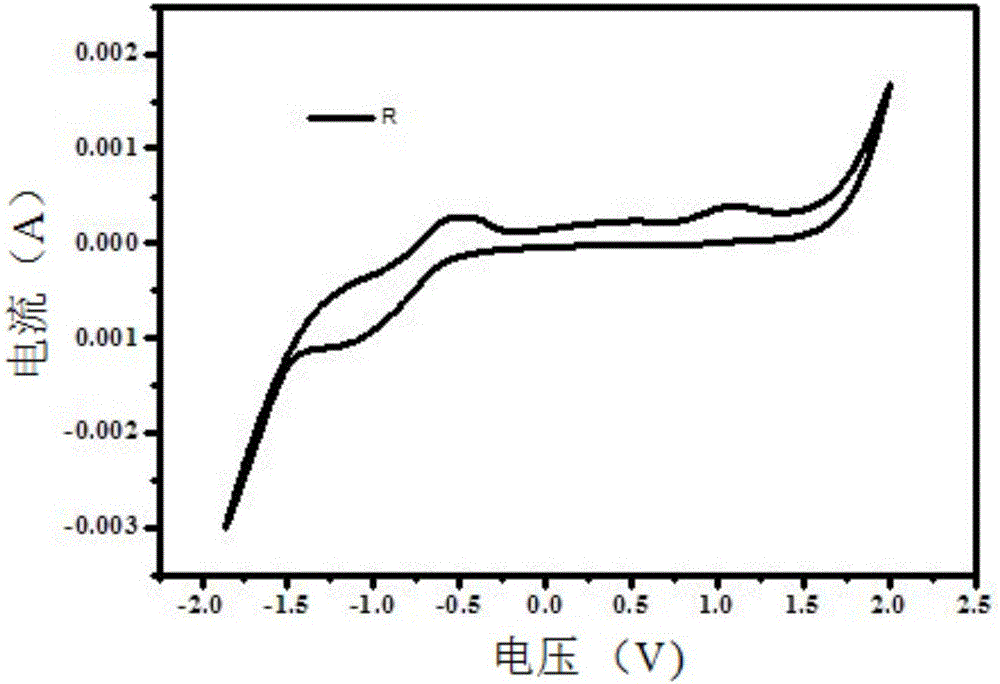

Preparation method of dye sensitizer based on phenothiazine

InactiveCN105859710AGood luminous materialLight-sensitive devicesOrganic chemistryElectron donor1-bromohexadecane

Owner:NANCHANG HANGKONG UNIVERSITY

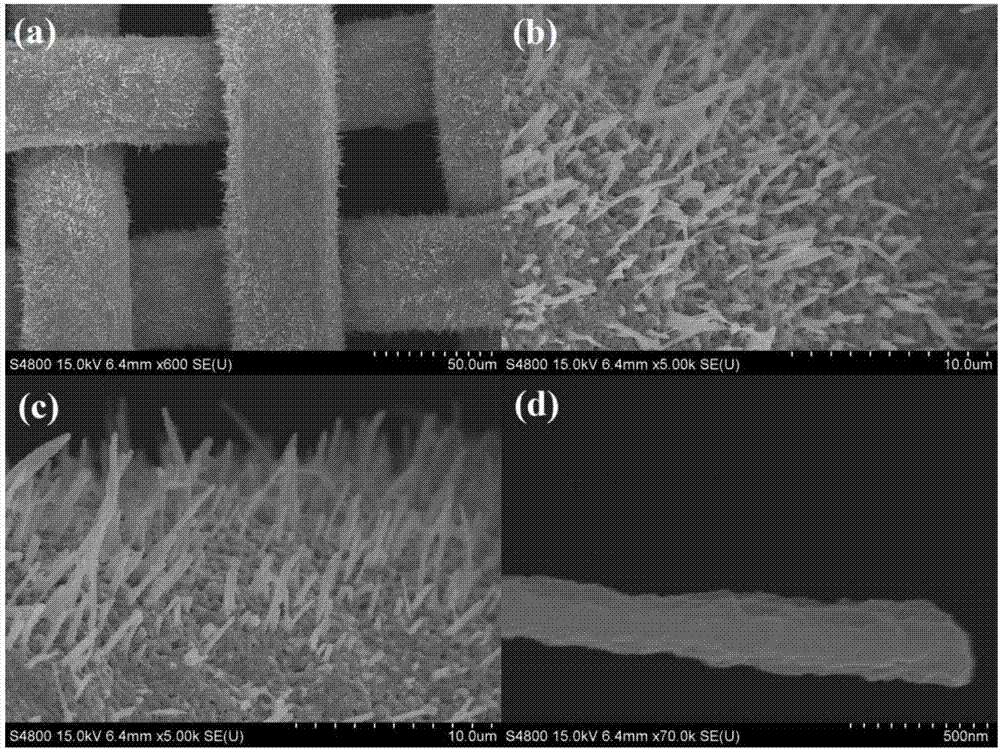

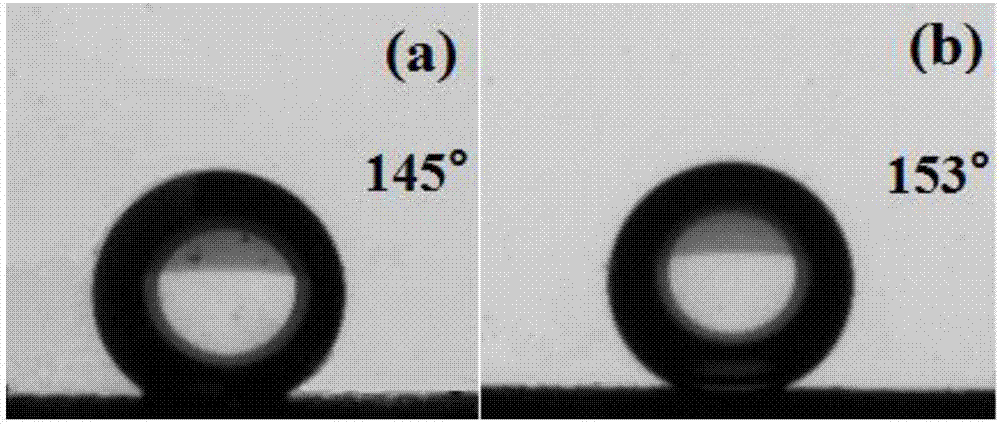

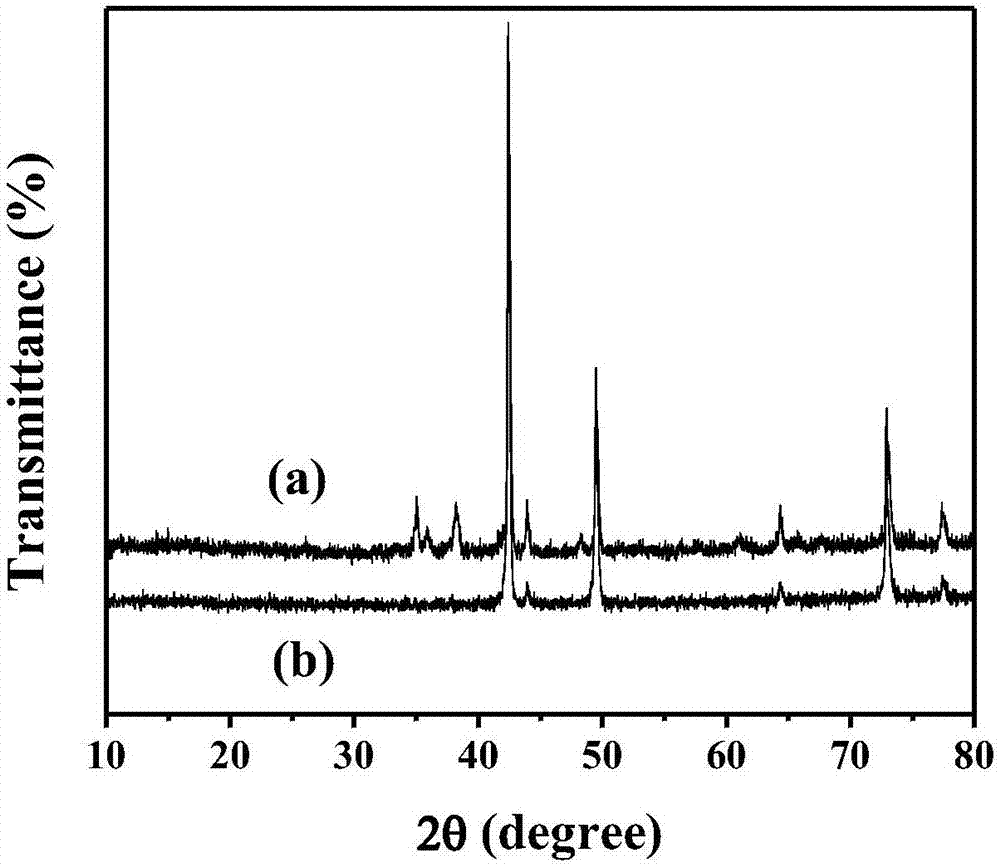

Copper oxide/carboxymethyl cellulose gel modified composite film, and making method and use thereof

InactiveCN106943883AEfficient separationSimple construction methodSemi-permeable membranesNon-miscible liquid separationCarboxymethyl celluloseComposite film

Owner:JIANGSU UNIV

Method for obtaining cucurbitacine B

Owner:烟台利天生物科技有限公司

Sewage pretreatment process used during organic product preparation

ActiveCN109896684APromote precipitationReduce saltOrganic compound preparationMultistage water/sewage treatmentOrganic layerSolvent

An embodiment of the invention discloses a sewage pretreatment process used during organic product preparation. The process includes: (a), adding a nonpolar solvent, sodium alcoholate and main and auxiliary raw materials into a synthesis kettle for reaction; (b), adding a saturated sodium salt solution into a water-washing neutralization kettle, cooling, adding reaction liquid in the synthesis kettle into the water-washing neutralization kettle, and titrating till being slightly acidic; (c), standing a solution in the water-washing neutralization kettle to obtain a lower-layer solid-liquid mixture and an upper-layer organic layer; (d), performing suction filtering on the lower-layer solid-liquid mixture to obtain sodium salt and a mixed solution; (e), taking the mixed solution in the step(d) as the solution added into the water-washing neutralization kettle in the step (b) for reutilization; (f), using water to wash the organic layer, and distilling or rectifying to obtain an organicproduct. The process can promote recycling of sodium salt and reutilizing of sewage, reduce salt in the sewage and substantially lower sewage yield, thereby reducing COD in the sewage and sewage treatment energy consumption and treatment cost.

Owner:ZHANGJIAJIE HONGYAN NEW MATERIAL TECH DEV CO LTD

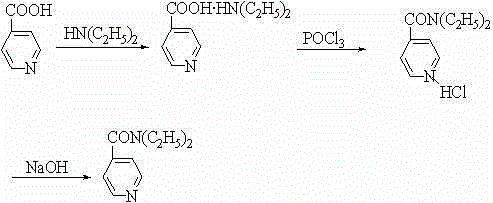

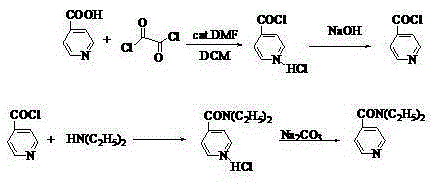

Method for preparing N,N-diethyl-3-pyridine carboxamide

InactiveCN104387319AHigh boiling pointLow boiling pointOrganic chemistryDistillationSynthesis methods

Owner:HENAN LINGXIAN SCI & TECHN PHARMA

Method for synthesizing N-benzyl-4-piperidinecarboxylate

ActiveCN107879969AShort reaction timeSave time and costOrganic chemistryOrganic layerBenzyl chloride

The invention belongs to the technical field of pharmaceutical chemicals and in particular discloses a method for synthesizing N-benzyl-4-piperidinecarboxylate. The process comprises the following steps: by taking isonipecotic acid and benzyl chloride as raw materials and taking 1,2-dichloroethane as a solvent, heating and reacting, adding water to wash after cooling, drying the organic layer, filtering and concentrating, thereby obtaining the N-benzyl-4-piperidinecarboxylate. According to the synthetic method, the used solvent 1,2-dichloroethane is concentrated and collected and can be recycled, the method is environmentally friendly, and the cost of the raw materials is greatly reduced.

Owner:SHANDONG CHENGHUI SHUANGDA PHARM CO LTD

Method for preparing hexyl-dioctyl phosphorus oxide

InactiveCN108610376AHigh purityThe reaction steps are simpleGroup 5/15 element organic compoundsRotary evaporatorDi-tert-butyl peroxide

Owner:四川中环检测有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap