Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3 results about "Apparent density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apparent density (pb) is the ratio between the apparent volume and dry specimen mass of a soil sample. The volume is limited by external specimen forces which include voids. Therefore, it is measured in kilograms per cubic meter (kg/m3).

High surface area and low structure carbon blacks for energy storage applications

ActiveUS20120214000A1Increase capacitanceEfficient separationPigmenting treatmentCapacitor and primary/secondary cellsApparent densityElectrochemical double layer capacitor

The present invention, in part, relates to a carbon black having a) a nitrogen BET surface area (BET) of from about 600 m2 / g to about 2100 m2 / g, b) a CDBP value in mL / 100 g of from about (−2.8+(b*BET)) to about (108+(b*BET)), where b is 0.087 and BET is expressed in m2 / g, and c) an apparent density (p, g / cm3) of at least about 0.820+q*BET, where q=−2.5×10−4, as determined at a compressive force (P) of 200 kgf / cm2 on dry carbon black powder. Energy storage devices, such as electrochemical double layer capacitors (EDLC's), containing the carbon black are also disclosed. Methods for making the carbon blacks and EDLC's made with them are also provided.

Owner:CABOT CORP

Manufacturing method of high-performance marine concrete

Owner:NANTONG ZHONGRUN CONCRETE

Production method of vanadium nitrogen alloy

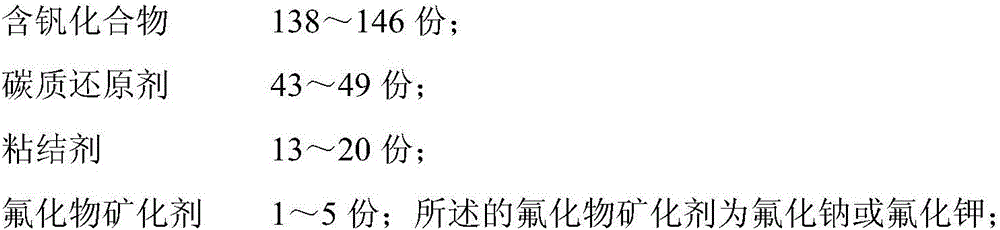

InactiveCN103014345BIncreased vanadium contentHigh apparent densityApparent densityVanadium nitride

Owner:HUNAN HONGYUAN RARE METAL MATERIALS

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap