Protease k liquid enzyme preparation for molecular biology and in vitro diagnostics

A protease and liquid enzyme technology, applied in the field of proteinase K liquid enzyme preparation, proteinase K liquid preparation and preparation, can solve the problems of limited protein purity, less need to consider storage stability, and unable to provide reference for preparation of proteinase K liquid preparation, etc. achieve high vitality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

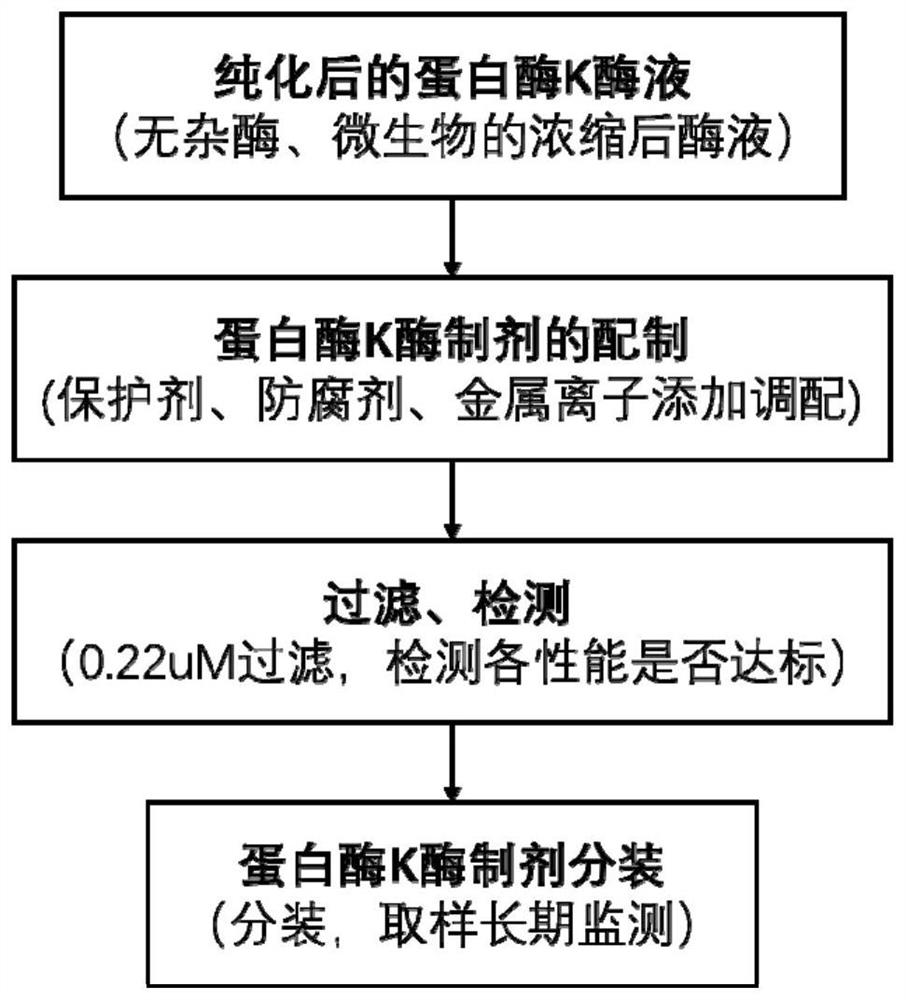

[0043] Example 1: Preparation of Proteinase K, Viability Assay and DNase, RNase and Bioburden Detection

[0044] Preparation of proteinase K: use recombinant yeast to ferment proteinase K, purify the fermentation supernatant containing proteinase K in the lower tank by ion exchange, and replace the purified enzyme solution with a suitable buffer solution for ultrafiltration and concentration to the appropriate concentration for viability assays and DNase, RNase, and bioburden assays.

[0045] (1) The principle of vitality detection:

[0046]

[0047] Proteinase K can hydrolyze hemoglobin into amino acids with phenolic groups. Under alkaline conditions, phenolic amino acids can reduce Folin’s phenol reagent to produce molybdenum blue and tungsten blue. The depth of the color is proportional to the content of phenolic amino acids. By measuring the absorbance of the hydrolyzate obtained by protease K catalyzing the hydrolysis of hemoglobin at 750 nm, combined with the standard c

Embodiment 2

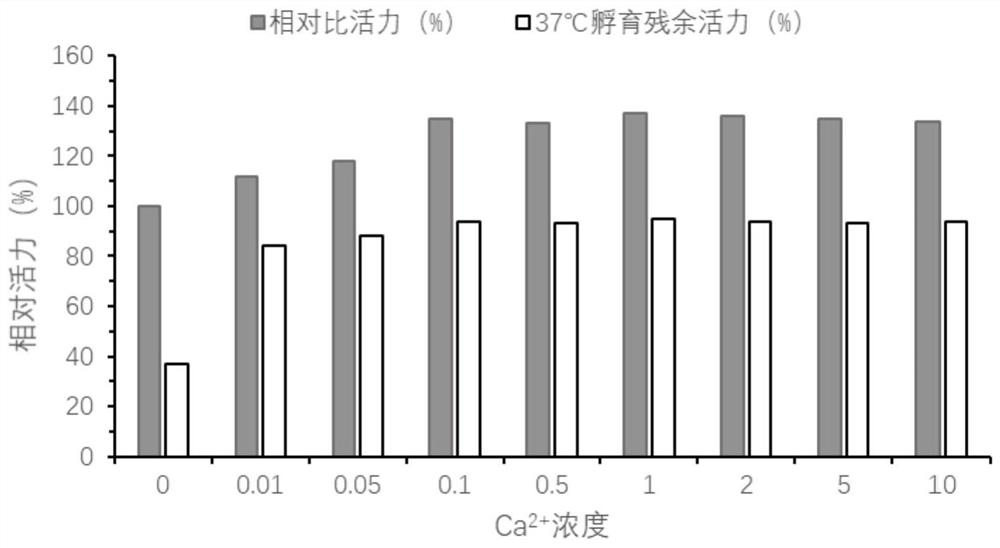

[0065]Preparation of proteinase K liquid enzyme preparation: select the proteinase K enzyme solution with a protein concentration of 22.1mg / mL and a specific activity of 49.4U / mg after buffer replacement and concentration in Example 1, add buffer: 50mM pH 6.0 acetic acid-acetic acid Sodium, protective agent: 20% (volume ratio) glycerin, preservative: 0.01% Sodium azide , Ca 2+ 0.5mM. The rest of the different protective agents can also refer to this concentration to prepare liquid proteinase K.

[0066] Storage stability of proteinase K liquid enzyme preparation at 37°C: take 10mL proteinase K liquid enzyme preparation sample and seal it and place it in a 37°C incubator (humidity 50%) for 1 month (31 days), and detect the activity of remaining proteinase K, The results showed that the residual activity of liquid proteinase K stored at 37°C for one month was still above 90%, and there was no microbial contamination, and no DNase or RNase activity. In the control group with

Embodiment 3~ Embodiment 8

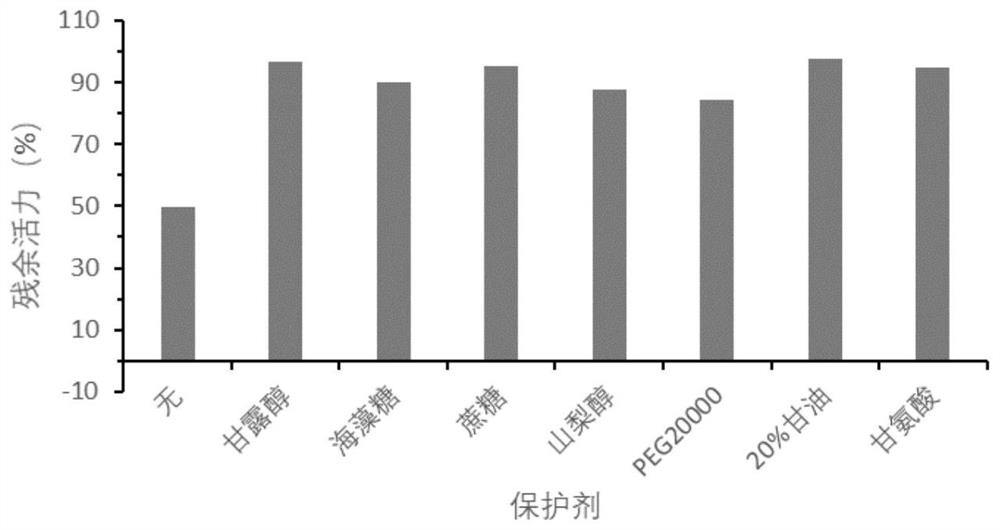

[0068] Embodiment 3~Example 8: the stability of different protective agents to proteinase K liquid preparation

[0069] Preparation of proteinase K liquid enzyme preparation: on the basis of embodiment 2, the protective agent is replaced by respectively: mannitol (embodiment 3), trehalose (embodiment 4), sucrose (embodiment 5), sorbitol (embodiment 6), PEG20000 (embodiment 7), glycine (embodiment 8), wherein, the addition amount of protective agent mannitol, trehalose, sucrose, sorbitol, PEG20000, glycine is according to protein quantity: protective agent quality=1:0.15 ratio is calculated.

[0070] Storage stability of proteinase K liquid enzyme preparation at 37°C: Take 10mL proteinase K liquid enzyme preparation sample and seal it and store it in a 37°C incubator for 1 month. K Solubility of Liquid Formulations. The results showed that no matter whether the protective agent was added or not, the liquid enzyme preparation was clear and transparent, and no insoluble matter was

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap