Enzymatic hydrolysis lactoprotein zinc complex compound and preparation thereof

A milk protein and complex technology, applied in the biological field, can solve the problems of absorption and utilization of side effects, achieve important social and economic significance, make the preparation process safe, and improve the absorption and utilization of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

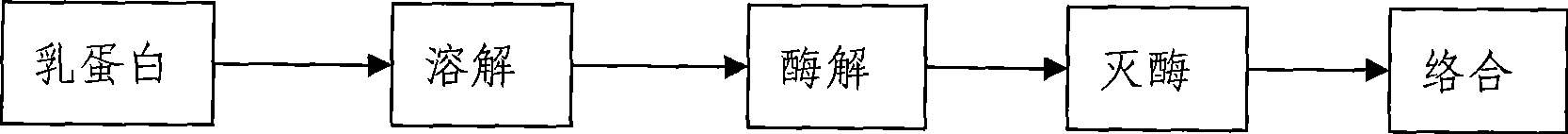

Method used

Image

Examples

Embodiment 1

[0024] Casein was from Northwest Biotechnology Company; alkaline protease was purchased from Novozymes Biological Co., Ltd.

[0025] Take 0.6kg of casein, make it into a 6% (w / v) protein solution, add 0.6 grams of alkaline protease, adjust the enzymolysis temperature to 42°C, enzymolysis time is 6h, and the pH value is 8.0 for enzymolysis. After the end of the enzymolysis, Inactivate the enzyme at 90°C for 10 minutes, and perform ultrafiltration with an ultrafiltration device (organic ultrafiltration membrane with a molecular weight cut-off of 10 kDa) to obtain a relatively pure milk protein hydrolyzate, which is cooled to room temperature for later use.

[0026] The enzymatic hydrolyzed milk protein solution, according to the bioactive peptide and ZnSO 4 (in Zn 2+ The mass ratio of calculated) is 4:1, the reaction pH value is 6.0, the reaction temperature is 45° C., and the complexation time is 30 minutes for the complexation reaction to obtain the milk protein bioactive pept

Embodiment 2

[0028] Crude cheese: from Xinjiang; casein from Northwest Biotechnology Company; alkaline protease from Novozymes Biological Co., Ltd.

[0029] Take 10 kg of crude cheese and 0.5 kg of casein, make it into a 3% (w / v) protein solution, add 5 grams of alkaline protease, adjust the enzymolysis temperature to 425°C, enzymolysis time 10h, and pH value 7.0 for enzymolysis, After the enzymatic hydrolysis, the enzyme was inactivated at 60°C for 30 minutes, ultrafiltration was performed with an ultrafiltration device (ceramic ultrafiltration membrane with a molecular weight cut-off of 10 kDa), cooled to room temperature, and freeze-dried for later use.

[0030] Under certain environmental conditions, take the dry powder of enzymatically hydrolyzed milk protein and prepare a solution with a concentration of 7%. 2 (in Zn 2+ Calculation) mass ratio is 1:1, the reaction pH value is 4.0, the reaction temperature is 55°C, and the complexation time is 20min for the complexation reaction to ob

Embodiment 3

[0032] Casein: from Northwest Biotechnology Company; whey protein was purchased from Beijing Yinhe Road Company; alkaline protease was purchased from Beijing Fangshan Enzyme Preparation Factory.

[0033] Take 1.0kg of casein and 0.5kg of whey protein to prepare an 8% (w / v) protein solution, add 20 grams of alkaline protease, adjust the enzymolysis temperature to 50°C, enzymolysis time for 8 hours, and pH value 9.0 for enzymolysis After the enzymatic hydrolysis, inactivate the enzyme at 90°C for 10 minutes, cool to room temperature, and set aside.

[0034] The whole milk protein hydrolyzate was mixed with zinc citrate (as Zn 2+ Calculation) mass ratio was 1:5, reaction pH value was 9.0, reaction temperature was 35°C, and complexation time was 50 min for complexation reaction to obtain milk protein bioactive peptide zinc complex.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap