Fibers and Nonwovens Made from uncross-linked alkyd oligomers

a technology of cross-linked alkyd oligomers and fibers, which is applied in the field of fibers formed from vitrification, can solve the problems of limiting the properties of the resulting fibers, difficult processing of fibers, and inability to reprocess or recycle fibers made from thermoset resins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Glycerol-Phthalate Oligomer

[0053]Glycerol (92.09 g, 1 mol) was added to a beaker and the beaker was placed on a plate situated under an overhead stirrer fitted with a 4-blade paddle mixing implement and a Brookfield viscometer. The mixing implement and viscometer was lowered into the glycerol and the sample was stirred with moderate heating. Phthalic anhydride (148.1 g, 1 mol) was slowly added to the stirring / warming glycerol. A thermocouple connected to a thermometer was inserted into the mixture to monitor the temperature, and the temperature of the solution was slowly raised to avoid overheating. The mixture became a clear, colorless solution around 125-130° C., and the temperature of the solution was then adjusted to 190° C. Some bubbling, which occurred quickly but at a moderate rate, was noticeable at this time. The solution continued to be stirred and heated at 190° C. until a desired viscosity was reached, generally 0.5 kg m−1 s−1 to 1 kg m−1 s−1. The solution

example 2

Non-Reactive Fiber Production Using Glycerol-Phthalate Oligomer

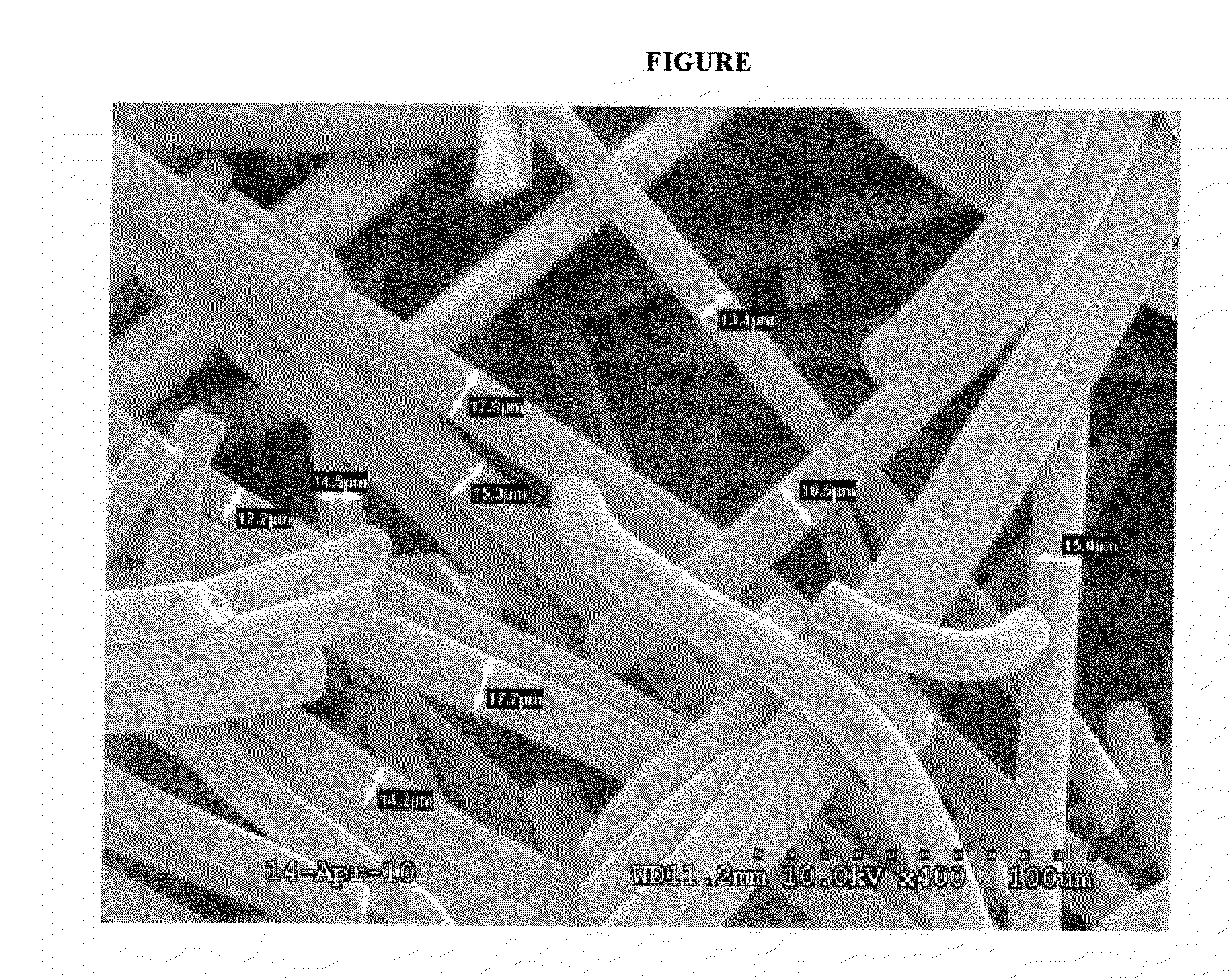

[0054]The glycerol-phthalate oligomer from Example 1 was warmed to about 200° C. in a heated well of an ITW Dynatec Dynamelt hot melt adhesive supply unit. The now fluid oligomer was then pumped (mass flow 0.3%, 0.8-1.0 rpm) via a Dynatec 8′ heated hose (about 200° C.) to and through a heated melt blown die (about 200° C.) with a 500 μm opening. The alkyd oligomers were blown into fluid molten fibers via pressurized air (100 psi, 260° C.) also passing through the melt blown die. These molten fibers cooled rapidly and vitrified into solid fibers, which were drawn to and collected on a moving vacuum screen affixed to a rotating, oscillating drum for further processing or storage. The sole FIGURE is an image of the uncross-linked alkyd resin fibers taken with a scanning electron microscope. The fibers shown in the image are water-stable and have surprisingly small diameters (e.g., 10 μm to 20 μm) that allow the production of p

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap