Large-dip-angle trash rack one-time forming suspension type sliding formwork and construction method

A technology of trash rack and large inclination angle, which is applied in water conservancy projects, infrastructure engineering, and cleaning of open water surfaces, etc. It can solve problems such as difficulty in construction quality control, increase in quality control, and safety management, and achieve favorable results The strength of concrete is guaranteed, the construction process is intuitive and controllable, and the effect of reducing unsafe hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Specific embodiments of the invention are provided below in conjunction with the accompanying drawings.

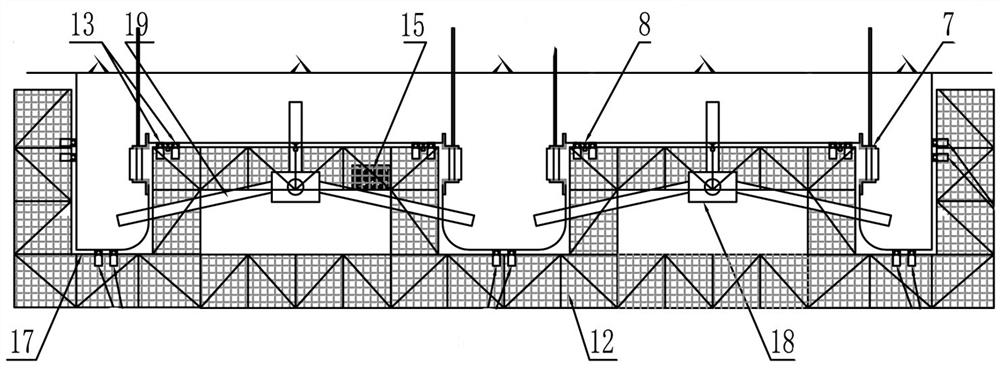

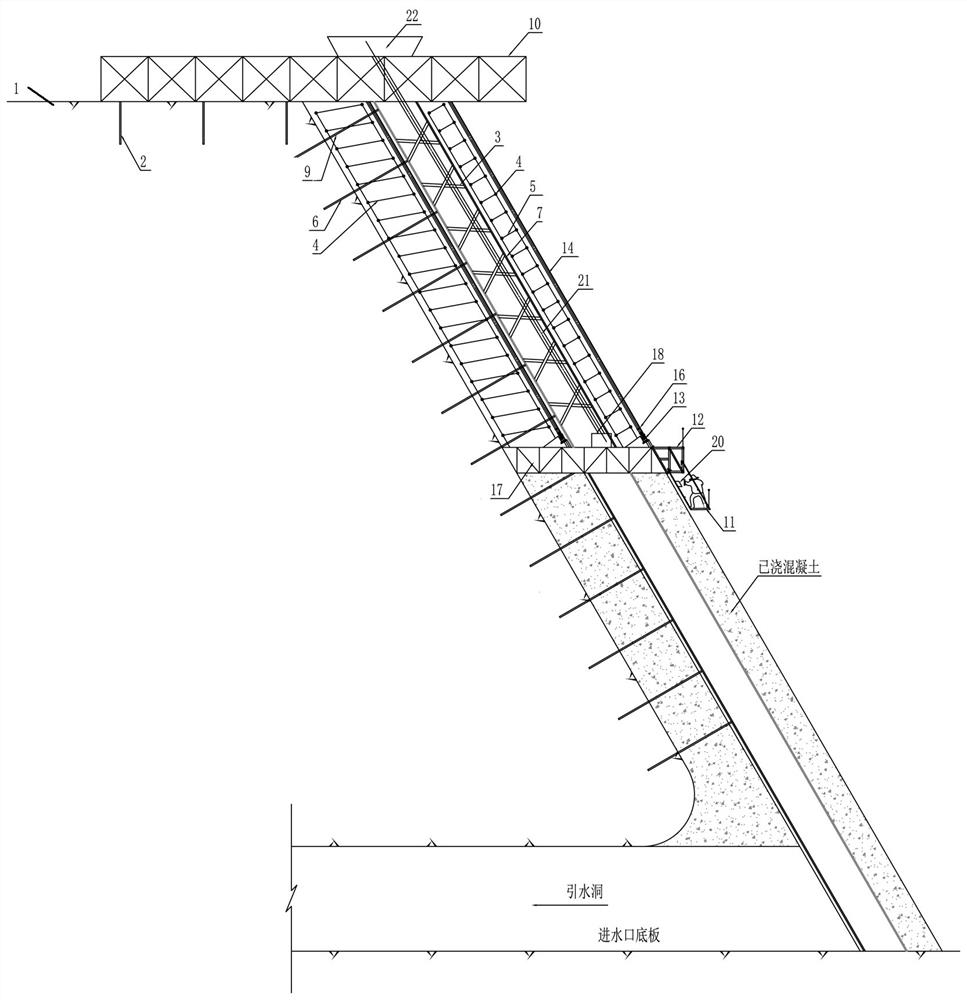

[0047] Such as Figure 1~Figure 2 As shown, a suspension type sliding form of a large-inclination trash rack is formed at one time, including a form system and a suspension system; the form system includes a template 17 in the shape of a trash rack spliced by panels, and ribs and ribs are arranged between the templates 17 The supporting truss; the upper surface of the formwork system is laid with a working platform 12; the working platform 12 is provided with a hydraulic control system; the suspension system includes a suspension support frame 10 of a truss structure, and the suspension support frame 10 passes through the anchor bar 2 and the steel support 3 It is fixed on the rock surface of the trash rack platform 1; multiple groups of suspension rods 14 are connected to the bottom of the suspension support frame 10, and the bottom ends of the suspension rods 14 ar

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap