Sleeve valve pipe for reinforcing pit bottom of water-rich pebble bed deep foundation pit and construction process

A pit bottom reinforcement and sleeve valve pipe technology, applied in the engineering field, can solve problems such as inability to form effective filling, large slurry diffusion, loose structure, etc., achieve good reinforcement effect, reduce slurry loss, and reduce fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

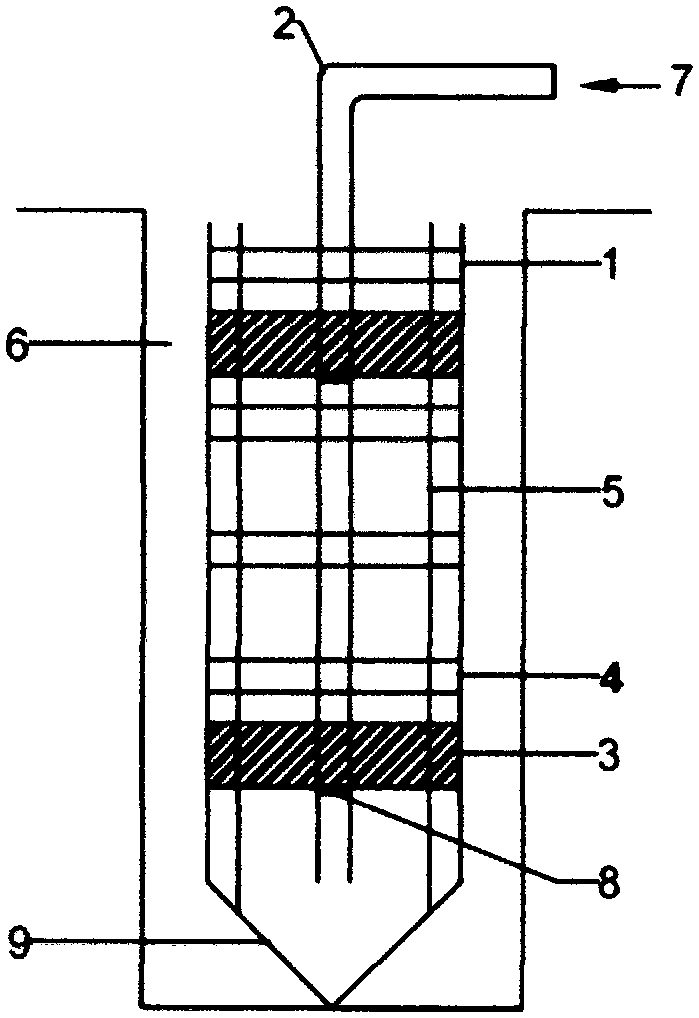

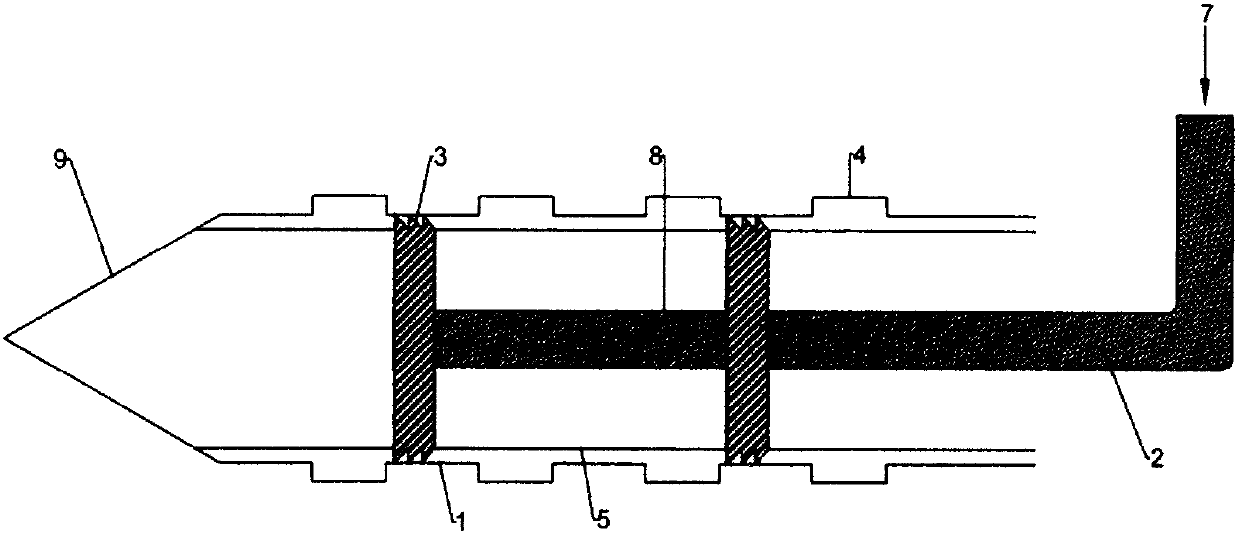

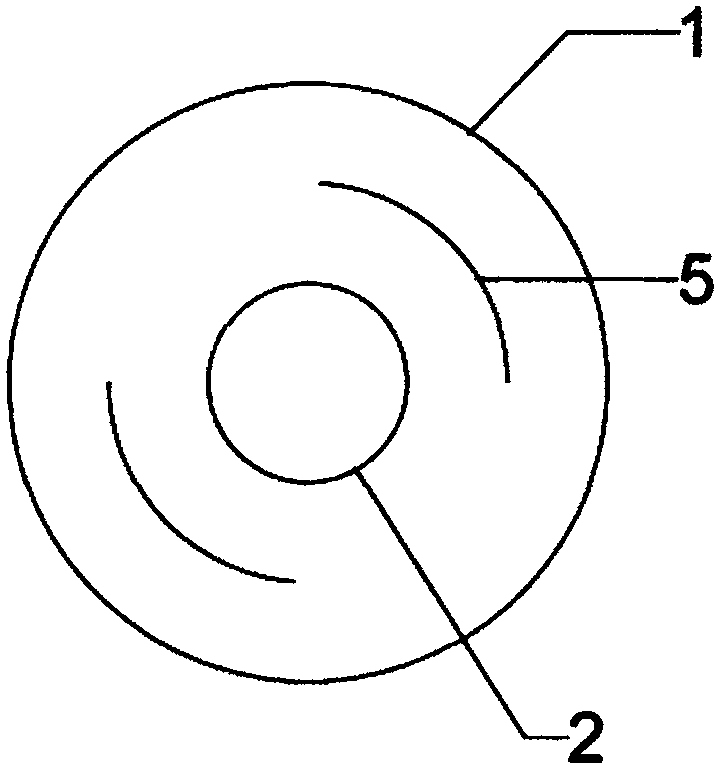

[0024] Embodiment of the present invention: it comprises sleeve valve pipe (1) and artificial sand filling layer (6). A tapered plug (9) is arranged at the end of the sleeve valve pipe (1), and a grouting pipe (2) and a drainage plate (5) are arranged inside. A grout stopper (3) and a joint (8) are arranged on the grouting pipe (2). The joint (8) on the grouting pipe (2) and the contact section of the grout stopper (3) are provided with a grout stopper rubber cup. The grouting liquid (7) is in the grouting pipe (2).

[0025] The sleeve valve pipe (1) is a water glass round pipe with a spiral pattern.

[0026] The diameter of the water glass round tube is 68mm-88mm, and the wall thickness is 3mm-5mm.

[0027] The joint (8) on the grouting pipe and the contact section of the grout stopper (3) are provided with 5-6 grout stopper rubber cups.

[0028] There are 4 rubber rafts on the sleeve valve pipe (1) surface.

[0029] The diameter of two drainage boards (5) in the sleeve val

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap