Connection method for wall sections of ultra-deep anti-seepage wall

A connection method and anti-seepage wall technology, which is applied in sea area engineering, construction, infrastructure engineering, etc., can solve the problems of inability to form a continuous ultra-deep anti-seepage wall, high risk of bottom pipe casting, and difficulty in pulling out joint pipes. Achieve the effects of reducing the overall construction cost, preventing pouring pipe plugging accidents, and reducing concrete interlayers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

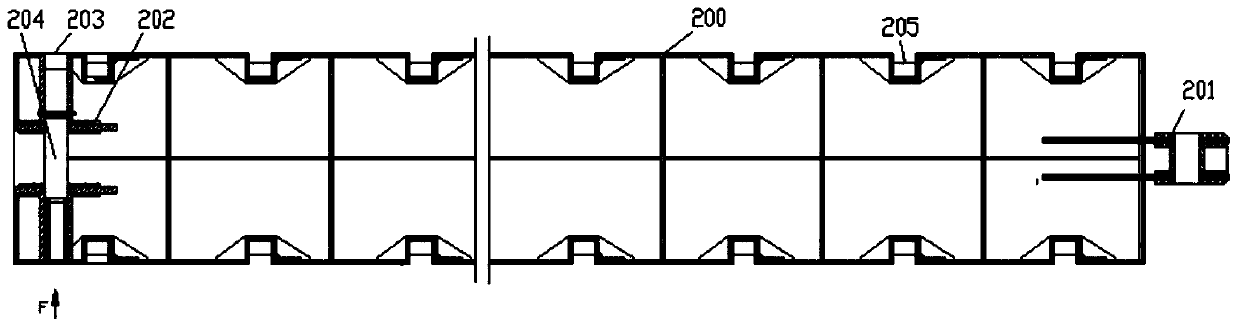

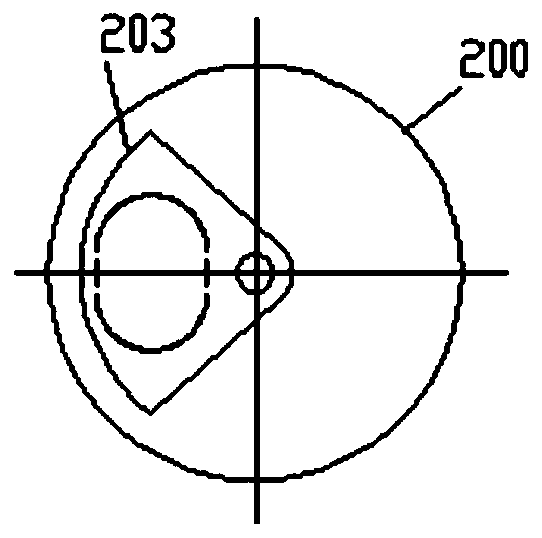

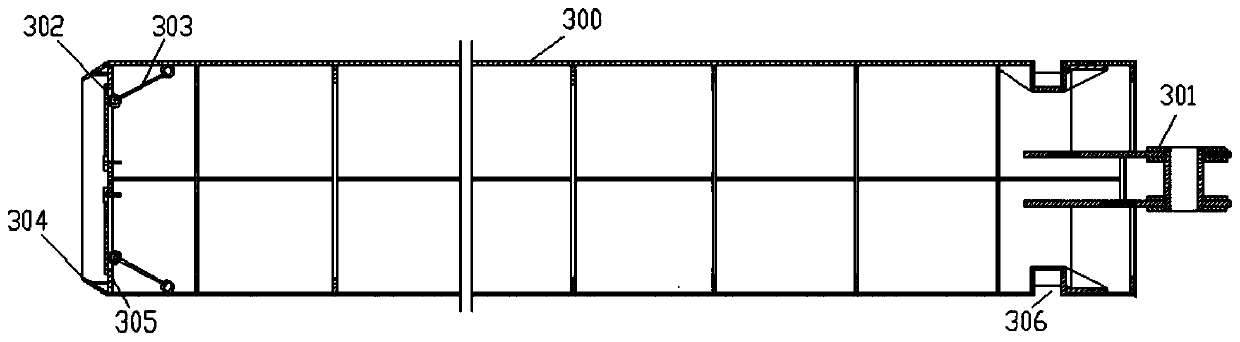

[0039] As one of the most important anti-seepage facilities in the foundation engineering of earth-rock dams, the anti-seepage wall plays an important role in ensuring the safety of the dam and reducing seepage in the reservoir area. In the construction of the cut-off wall, since the joint pipe method is the advanced technology for the joint treatment of the concrete cut-off wall construction, it has incomparable advantages over other joint connection technologies: firstly, the joint hole shape quality of the construction using the joint pipe method is better , the hole wall is smooth, and it is not easy to form a thick mud skin at the hole end. At the same time, because of its circular arc specification, it is also easy to scrub the joint without leaving any dead ends, which can ensure the joint quality of the joint. Secondly, due to the establishment of the joint pipe, the time for setting the joint concrete is saved, and the work efficiency is improved, which plays a very impor

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap