Concrete charging bucket landing anti-swing system and method for dam construction cable crane

A concrete and cable machine technology, applied in the direction of the clockwork mechanism, infrastructure engineering, hoisting device, etc., can solve the problems of time-consuming and labor-intensive, affecting the quality and progress of the project, unable to locate the tank in the concrete warehouse, etc. The effect of reducing the strength of manual tank support, improving time efficiency and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

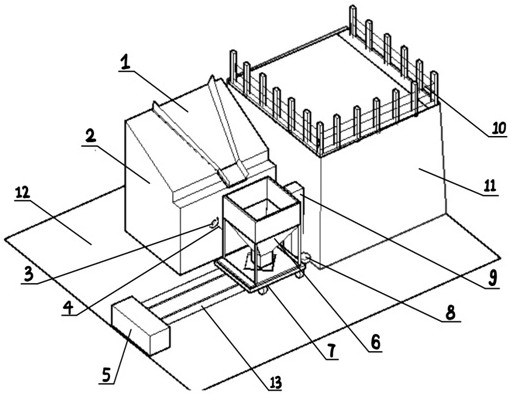

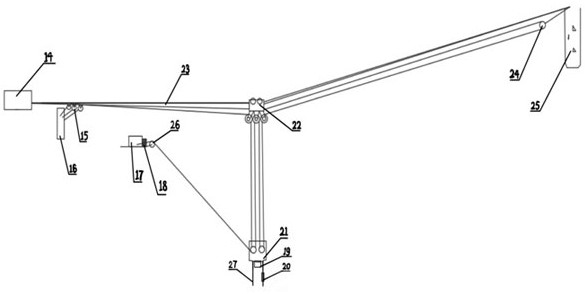

[0028] The landing anti-swing system of the concrete material tank of the dam construction cable crane includes a feeding positioning mechanism and a traction speed regulating mechanism.

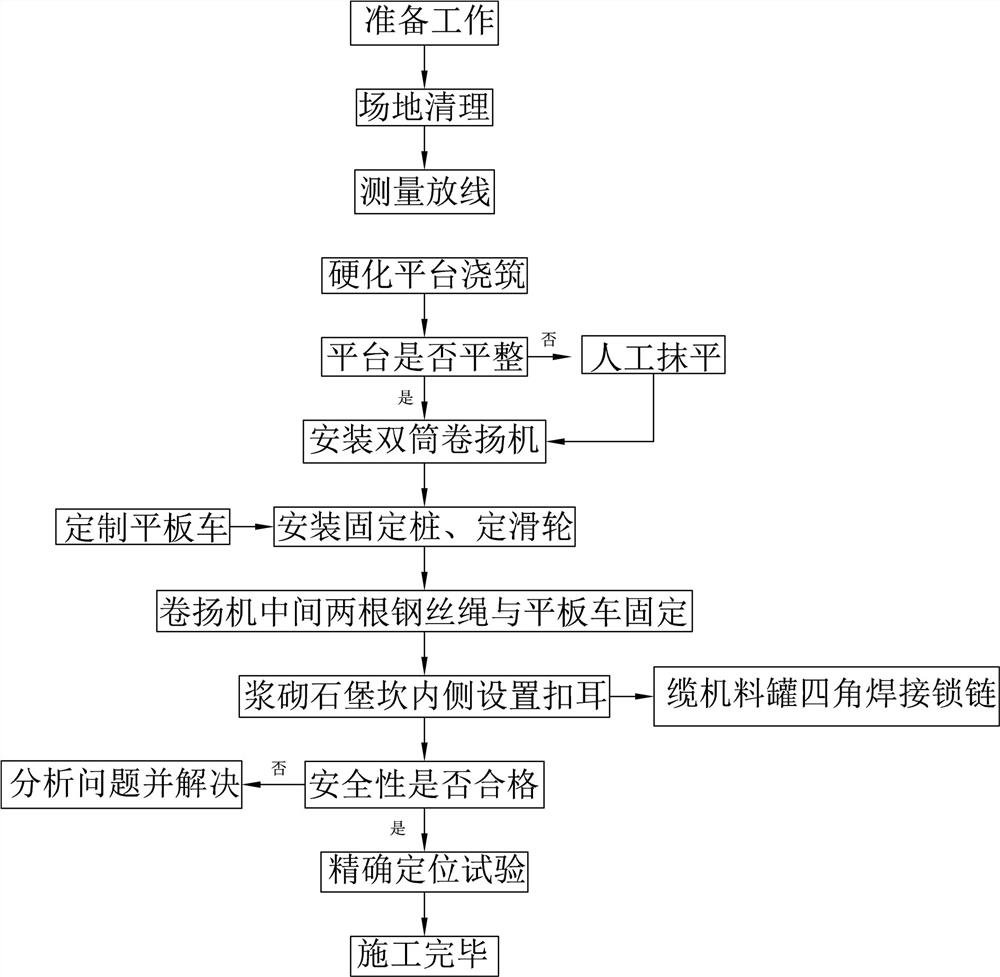

[0029] like figure 1 , Figure 4 As shown, the feeding positioning mechanism includes a hardening platform 12, and the hardening platform 12 is formed by pouring concrete. A double-tube winch 5 and two fixed pulleys 8 are installed on the hardening platform 12 , and the first rope 13 is wound on the double-tube winch 5 and looped back through the fixed pulley 8 . Flat tackle 7 bottoms are connected with two first ropes 13 inside, and the flat tackle 7 upper ends are placed with cable machine feed tank 6. When the double-tube winch 5 starts, the cable machine feed tank 6 on the flat block 7 can be driven by two first ropes 13 to move back and forth.

[0030] In addition, a first fortress 2 is built on the hardening platform 12, and the first fortress 2 is inlaid with a hopper 1, and the disch

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap