Online steel pipe weighing and stacking device

A stacking device and weighing technology, which is applied in the field of online steel pipe weighing and stacking devices, can solve problems such as shipping efficiency, unsatisfactory cost control, unstable placement, and reduced shipping efficiency, so as to achieve accurate positioning Sexuality and automation, good operation stability, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below in conjunction with accompanying drawing:

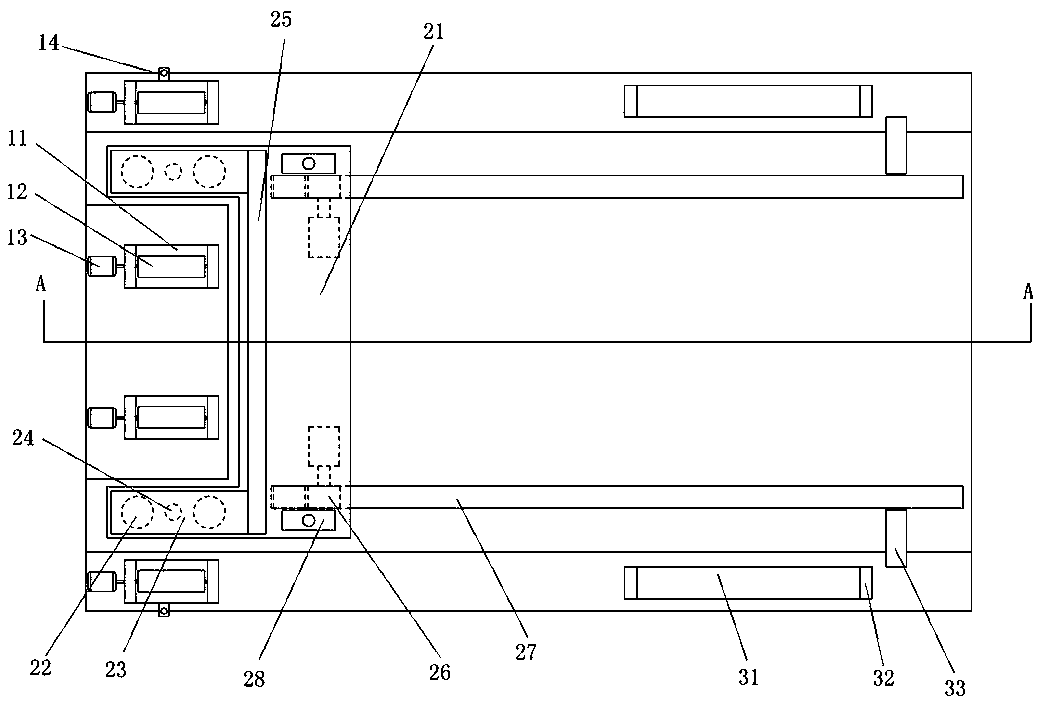

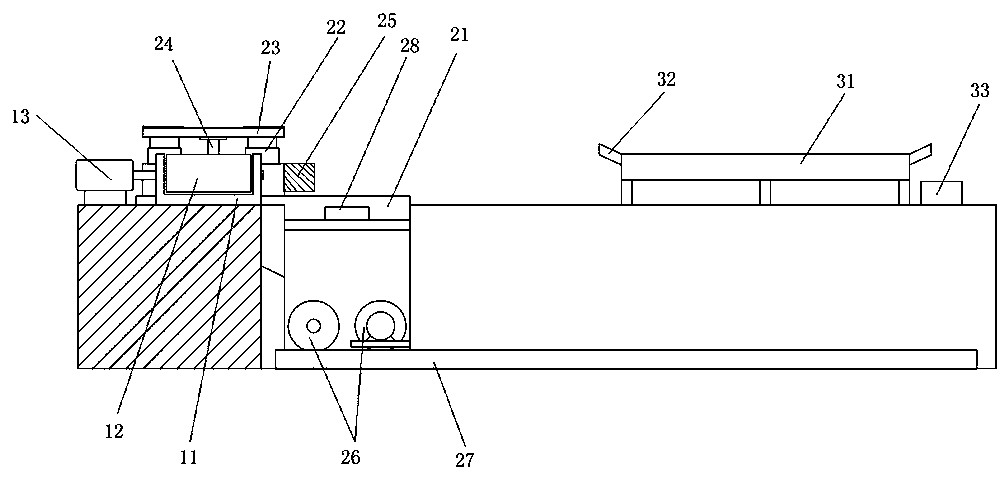

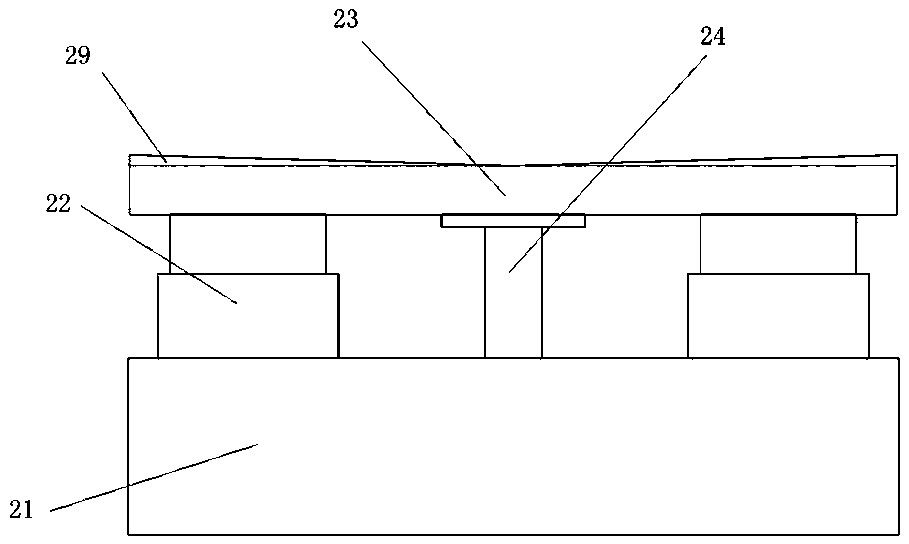

[0025] Such as figure 1 , 2 3. An online steel pipe weighing and stacking device shown in 3 includes a supporting device, a walking device and a stacking device that are sequentially arranged from upstream to downstream. The above-mentioned overall device is arranged in the foundation pit, and the foundation pit is rectangular in shape when viewed from above. The short side on one side is the upstream end, and the short side on the other side is the downstream end. The supporting device is set outside the edge of the upstream end of the foundation pit, the walking device is set in the foundation pit and runs in it, and the stacking device is set on both sides of the foundation pit. The long side is close to both sides of the downstream end, as a link in the production line, the end of the steel pipe processing equipment upstream of the production line is arranged on one side of

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap