Variable-flame-path type blank stacking machine blank-clamping blank-drawing and blank-separating system suitable for micro-rectangular kiln car

A technology of rectangular and blank stacking machines, which is applied to the stacking of objects, the unstacking of objects, and internal accessories, etc., which can solve the problems of large space occupation, high manufacturing cost, and low brick pass rate, etc., and achieve high work efficiency. Low manufacturing cost and good blank code effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

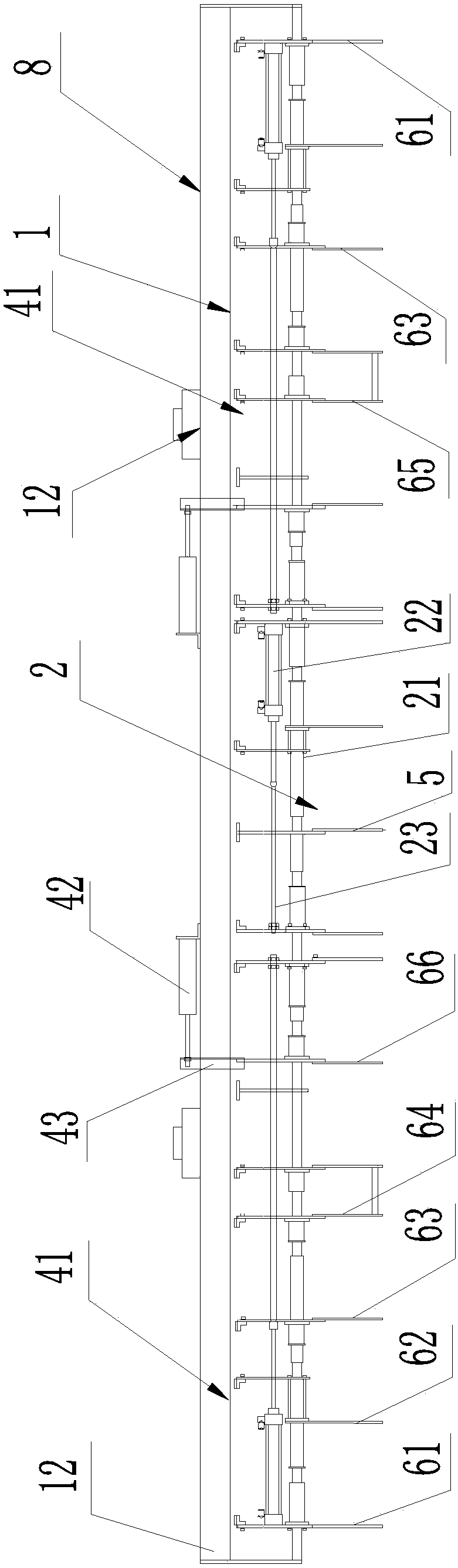

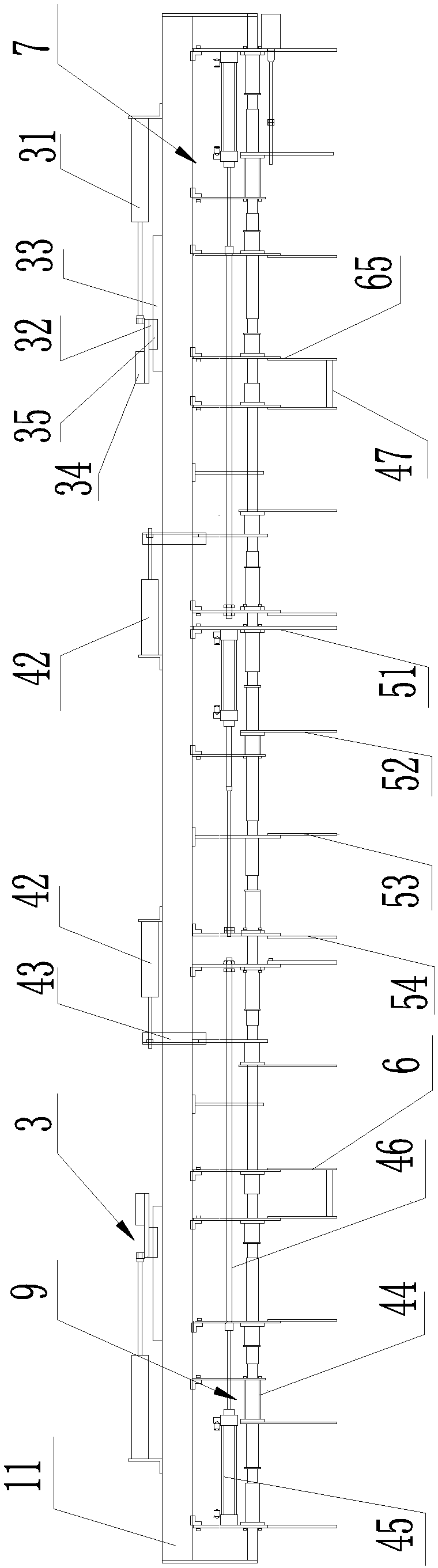

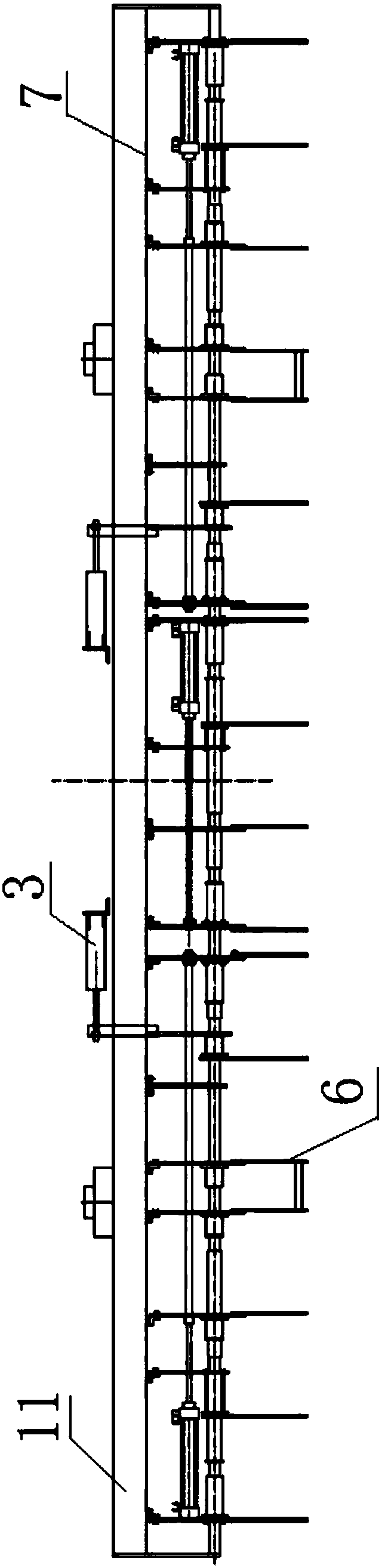

[0038] Referring to the accompanying drawings, it can be seen that the blanking and drawing separation system of the changing channel type billet machine suitable for micro-rectangular kiln cars includes a compact frame 1, and the compact frame 1 includes a plurality of odd-numbered clamping bars 11 with odd numbers , and a plurality of even-numbered even-numbered clip bars 12, characterized in that:

[0039]The odd-numbered clamping bars 11 and the even-numbered clamping bars 12 are all made of aluminum alloy plates with an integrated structure, and the middle lower ends of the odd-numbered clamping bars 11 and the middle lower ends of the ev

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap