Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

19 results about "Continuous operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In telecommunication, continuous operation is an operation in which certain components, such as nodes, facilities, circuits, or equipment, are in an operational state at all times. Continuous operation usually requires that there be fully redundant configuration, or at least a sufficient X out of Y degree of redundancy for compatible equipment, where X is the number of spare components and Y is the number of operational components.

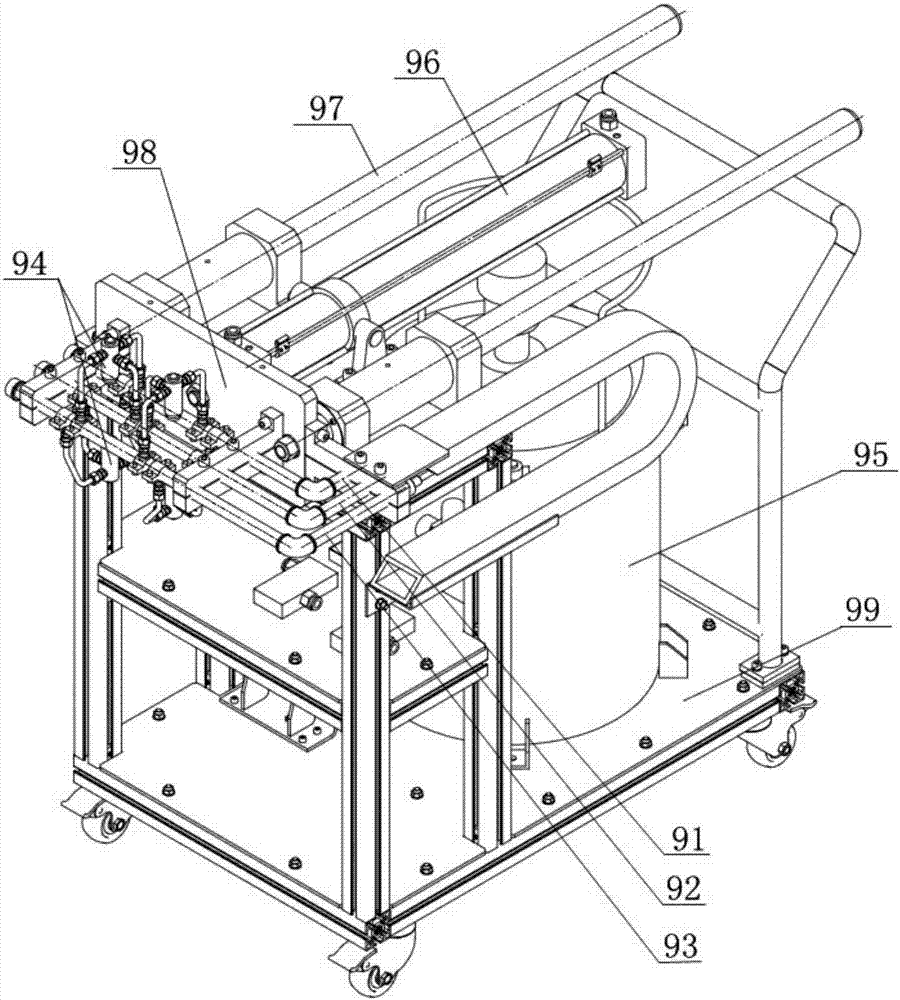

Chain-plate compost turning machine

InactiveCN103497017AImprove efficiencyLong turning distanceBio-organic fraction processingOrganic fertiliser preparationDrive wheelAutomatic control

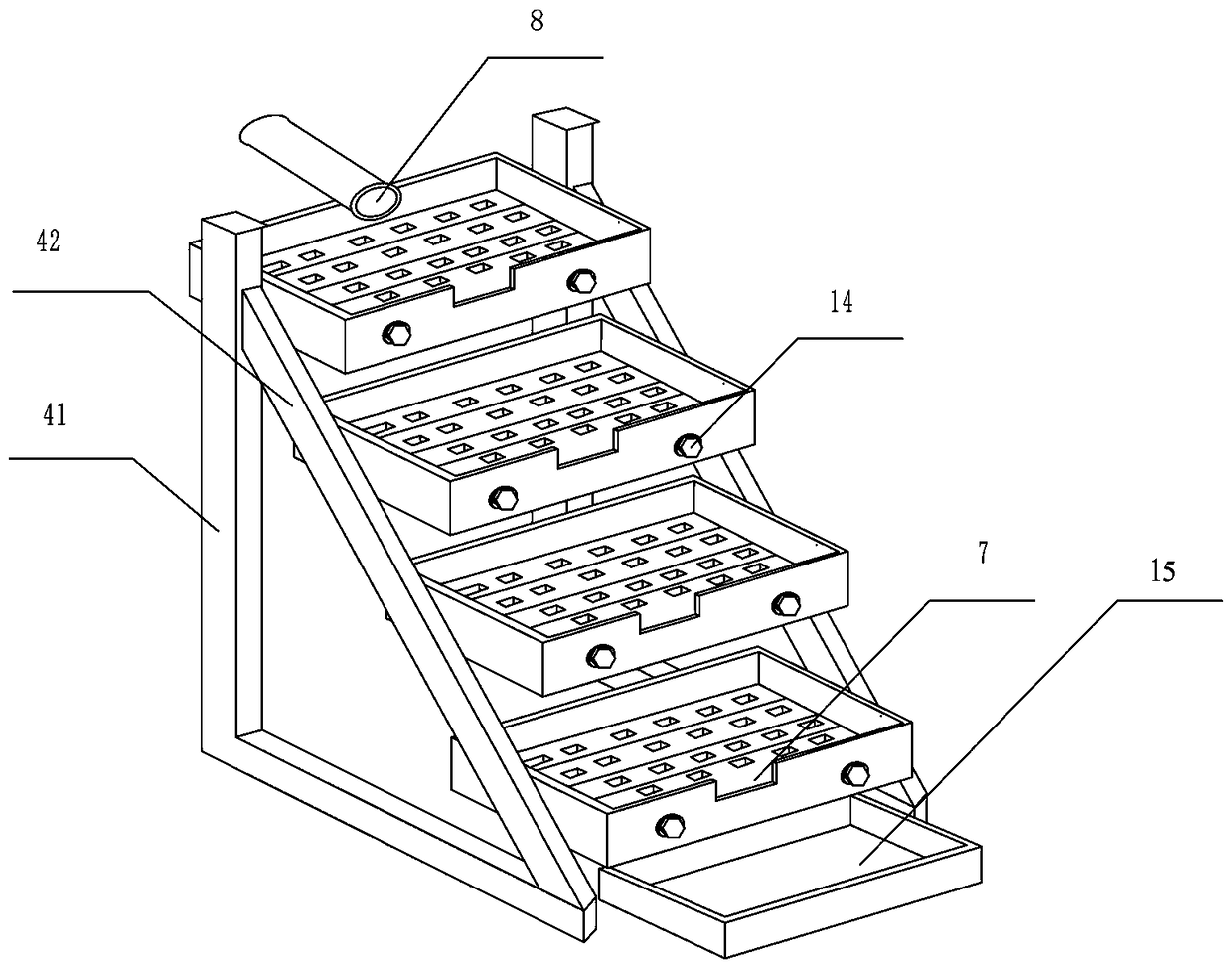

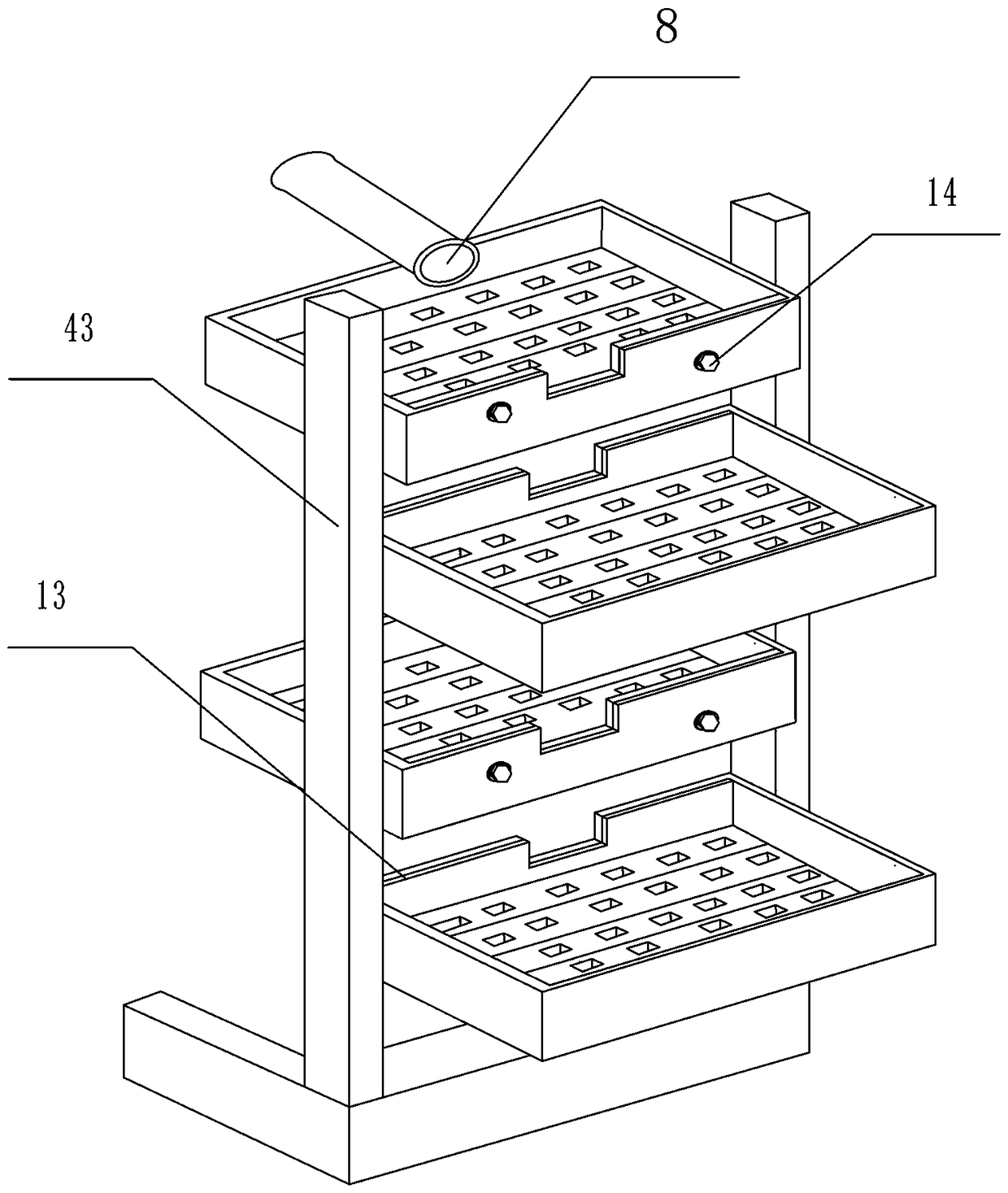

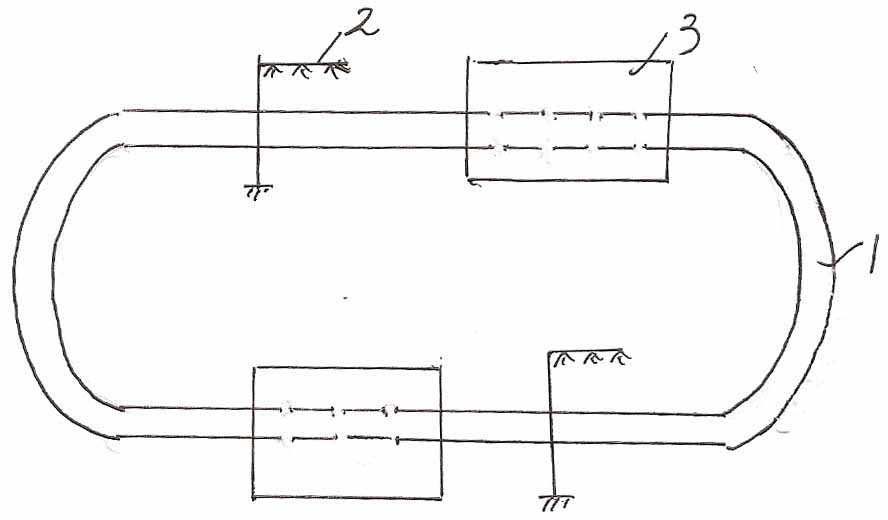

The invention discloses a mechanical device, in particular a chain-plate compost turning machine for production of organic compost. The chain-plate compost turning machine comprises a frame, a travelling mechanism, a chain-plate turning mechanism, a lifting system and an automatic control system. A driven wheel set and a driving wheel set are mounted at front and rear ends of the lower portion of the frame respectively. The driving wheel set is driven by a travelling motor set which is connected through a spindle. The driving wheel set is disposed on a travel rail of the travelling mechanism, and meanwhile, the chain-plate turning mechanism and the lifting system are driven by corresponding motors, thus coordinative operation of the systems is achieved. The chain-plate compost turning machine has the advantages that two travelling motors are used for control so that continuous operation of the machine is ensured; compost material in a fermenting tank is thrown, aerated and mixed by a rotary chain-plate hooked-tooth turning and scattering mechanism, efficiency is high, turning distance is long, turning is thorough, fermenting period can be shortened effectively, and compost quality is improved; the chain-plate compost turning machine is more adaptive and flexible.

Owner:HANGZHOU HUAXIN MECHANICAL & ELECTRICAL ENGINEERING CO LTD

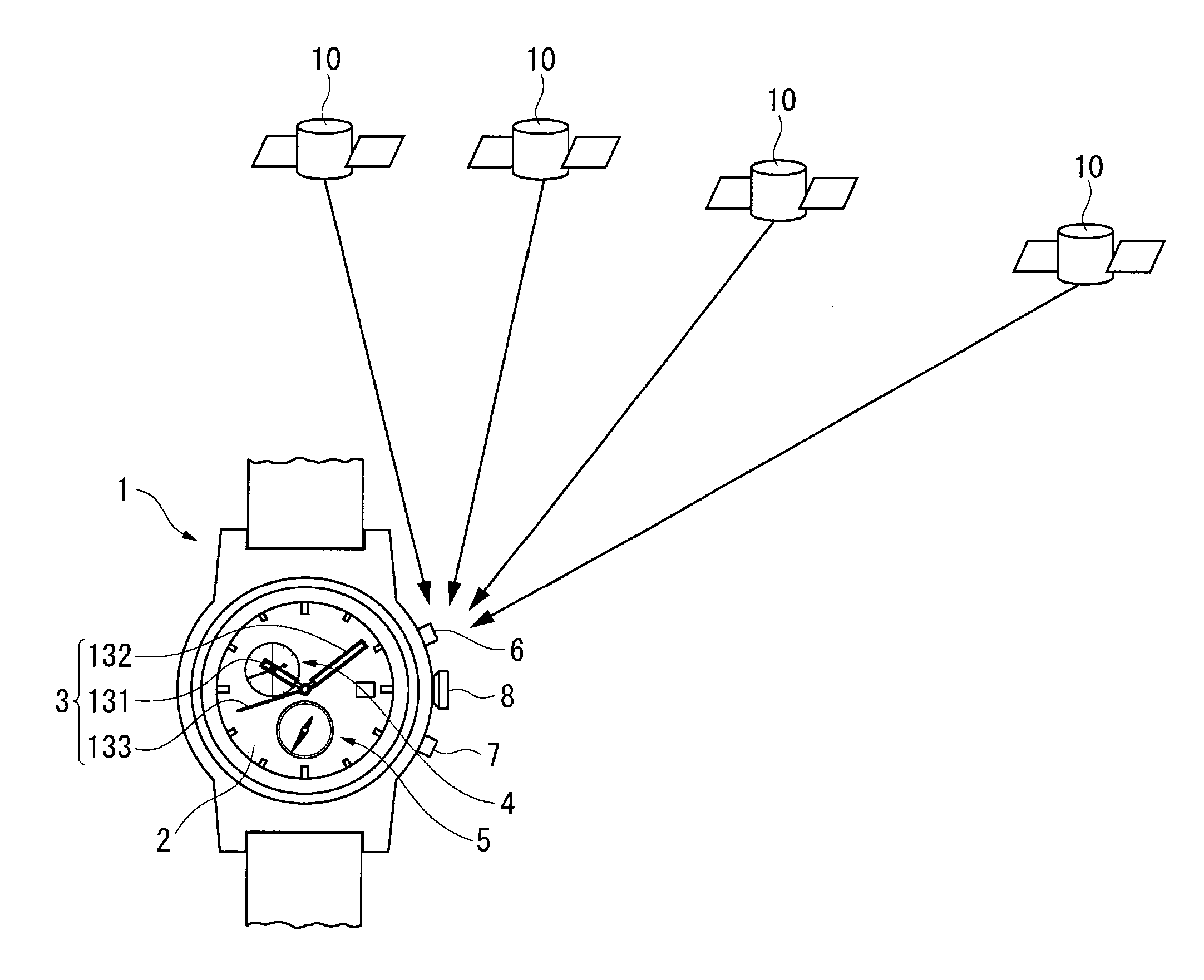

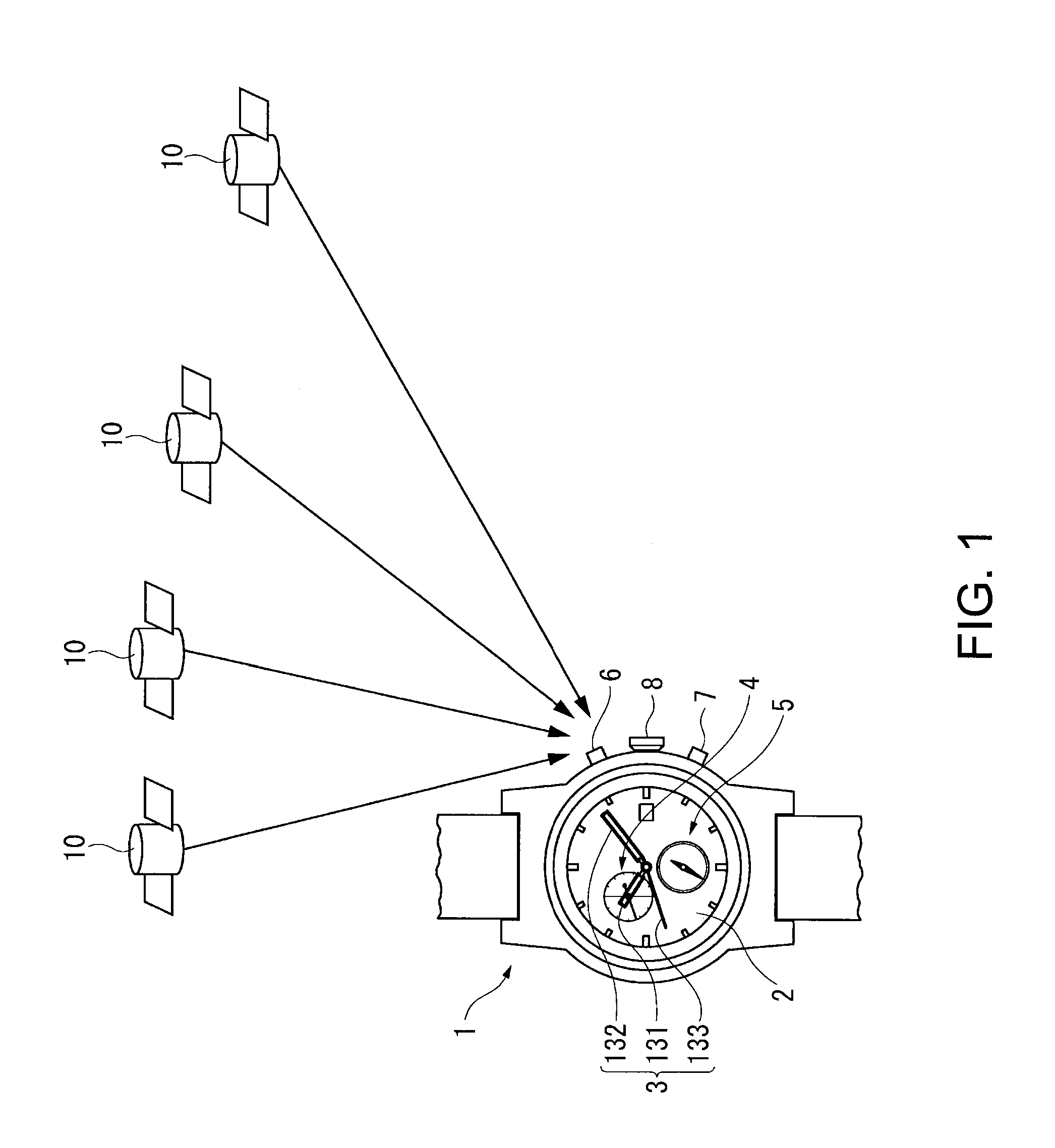

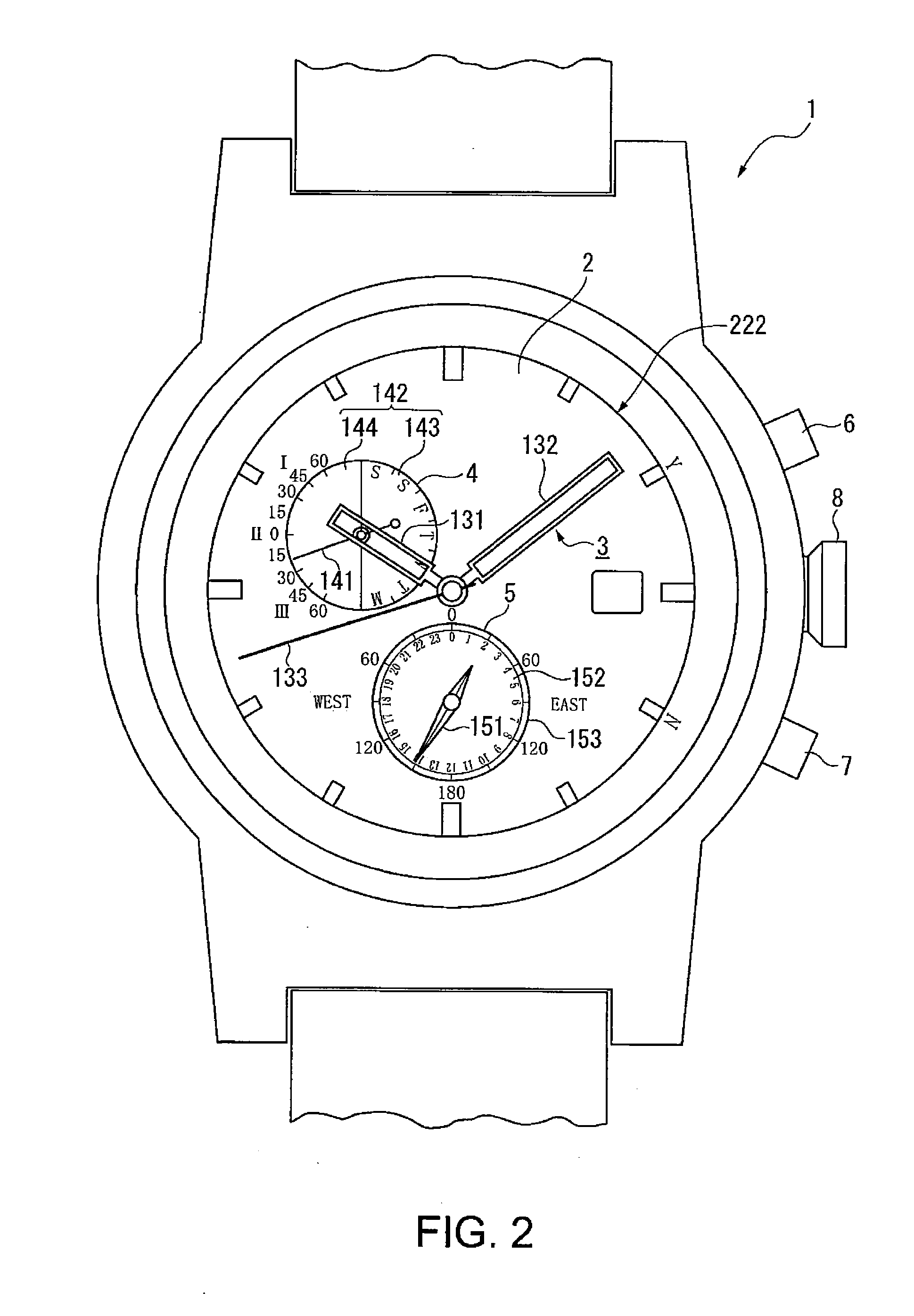

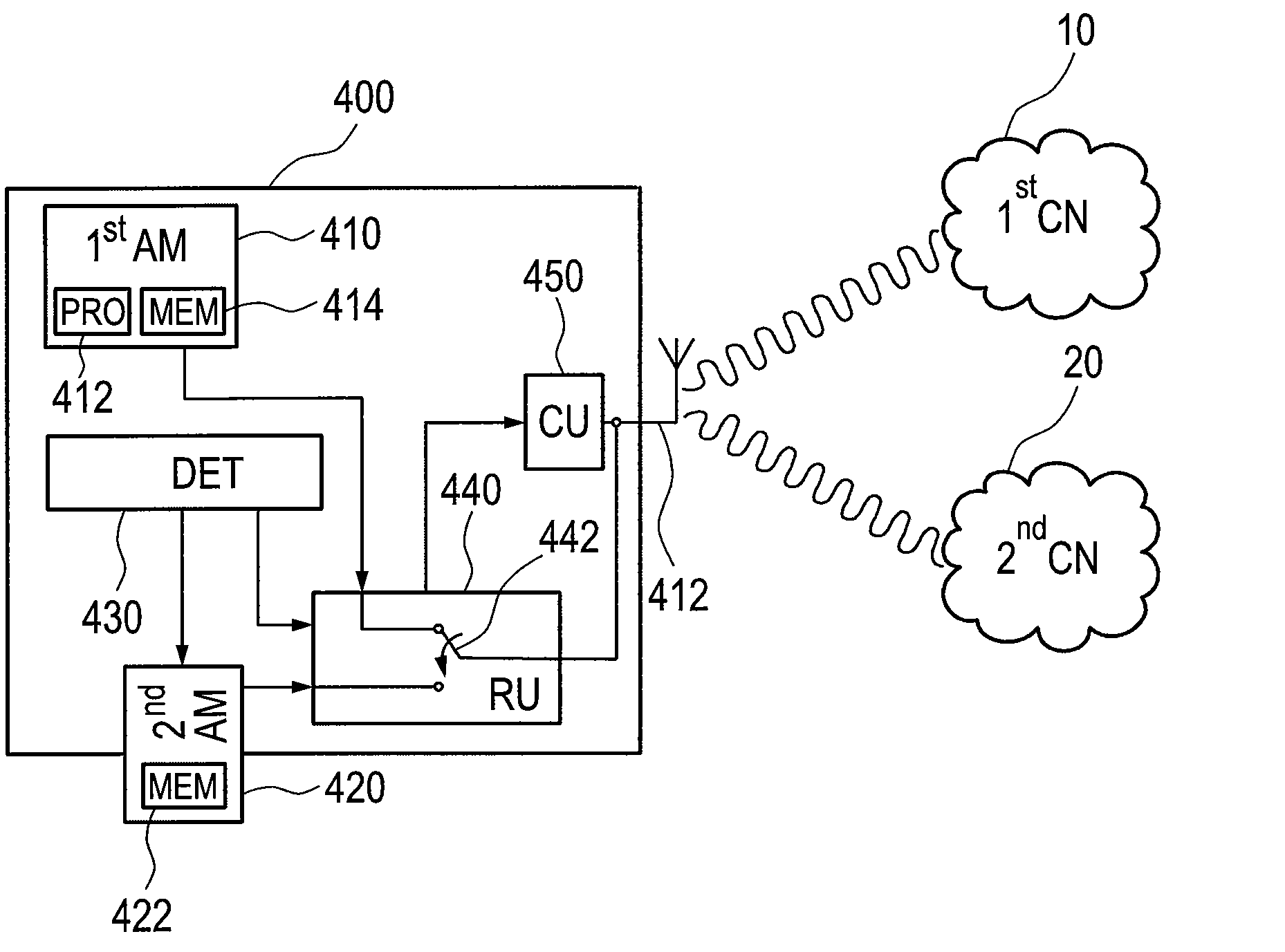

Electronic Timepiece and Electronic Device

ActiveUS20130051186A1Easy to checkImprove usabilityVisual indicationsSynchronous motors for clocksTime informationEngineering

Owner:SEIKO EPSON CORP

SIM Information Based SIM Validation

InactiveUS20120315875A1Quick implementationAvoid replacementUnauthorised/fraudulent call preventionEavesdropping prevention circuitsContinuous operationVIT signals

Owner:CINTERION WIRELESS MODULES

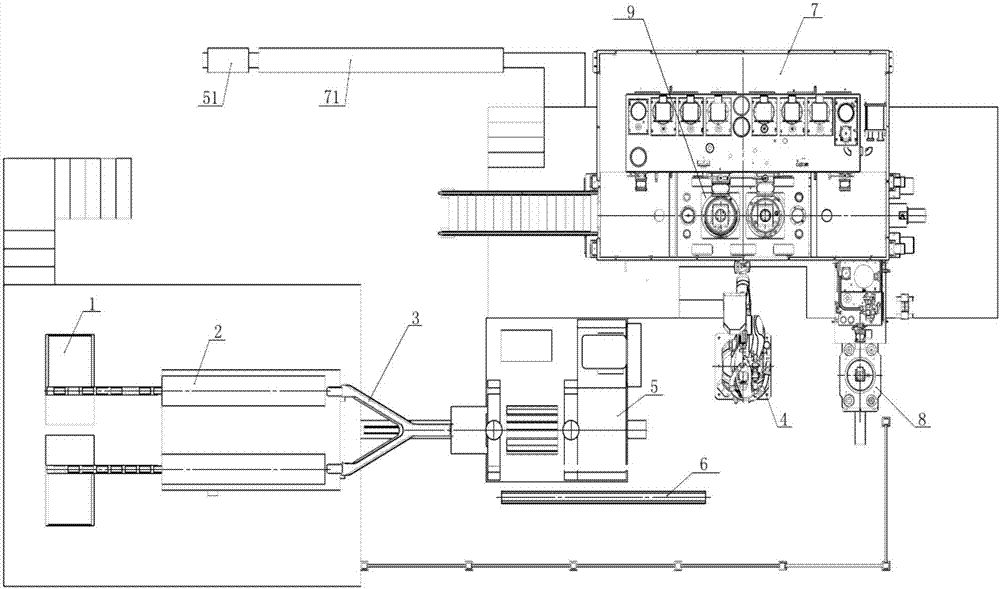

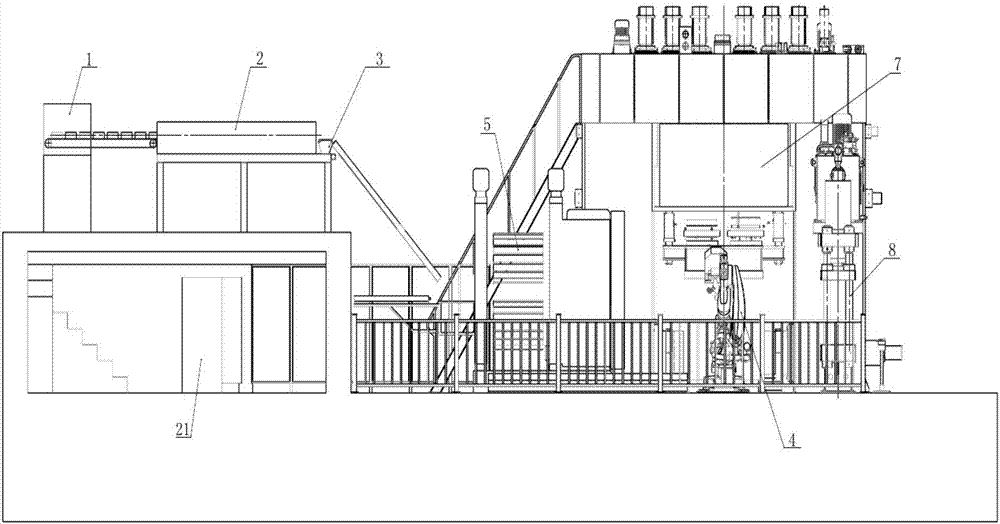

Valve body closed type multidirectional precision forging production line

ActiveCN106955955AIncrease profitReduce wasteValve arrangementsForging/hammering/pressing machinesProduction lineAutomatic control

Owner:HUZHOU MACHINE TOOL WORKS

Method for detecting events on cellular comm. network

InactiveUS20090186610A1Radio/inductive link selection arrangementsWireless communicationContinuous operationComputer science

A system and method that detects related events in the cellular comm. network and its derivatives with minimum overhead and in a changing cellular environment, both in the installation stage of a system, as well as during continuous operation.

Owner:AVNI OFER +1

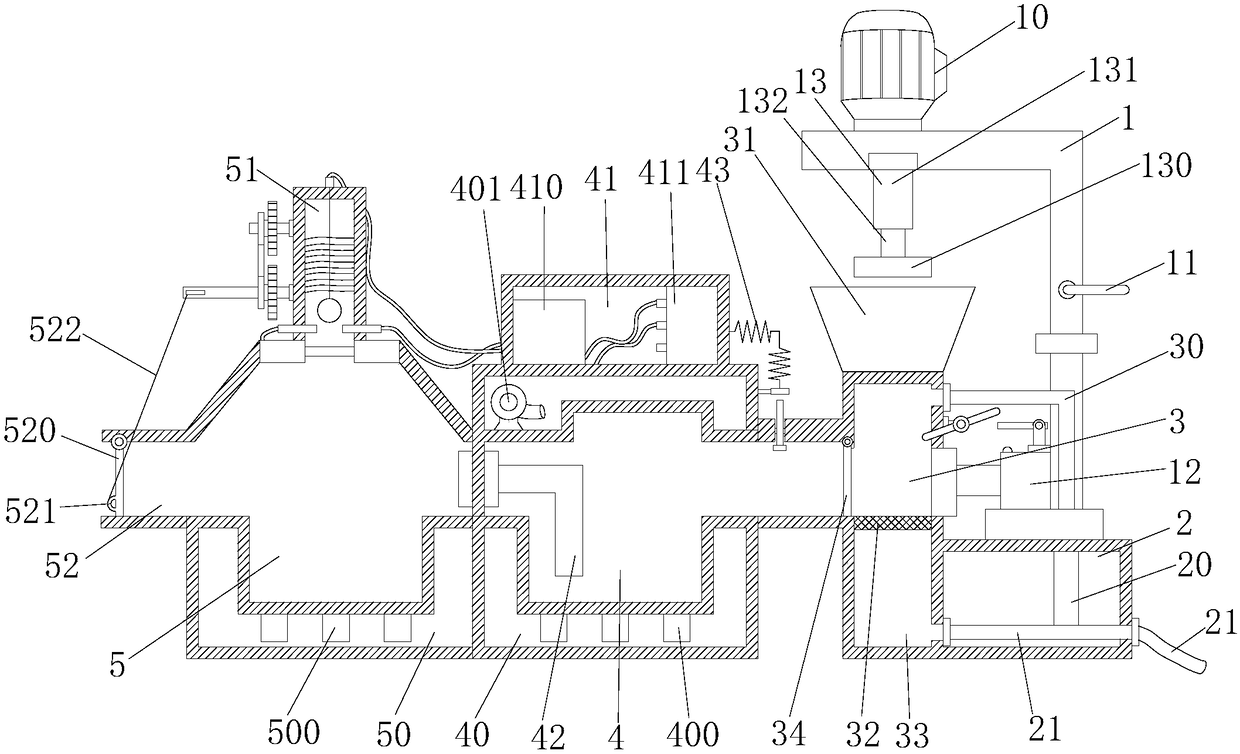

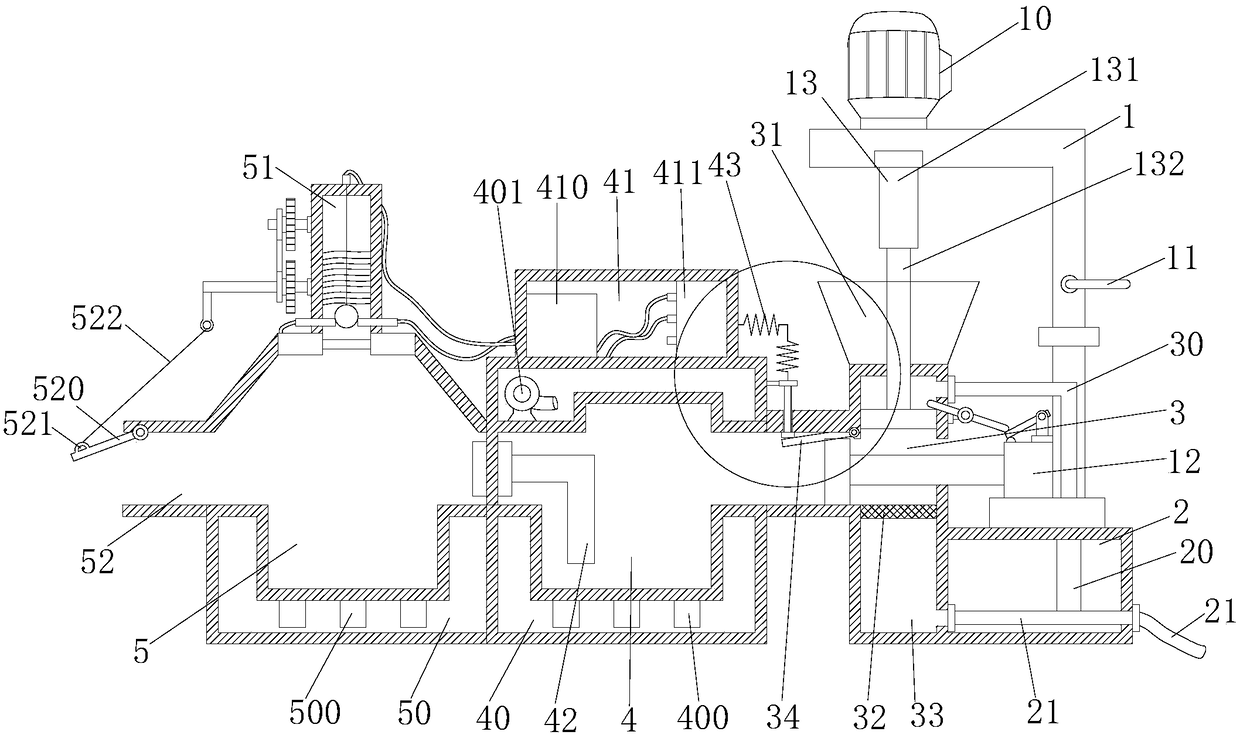

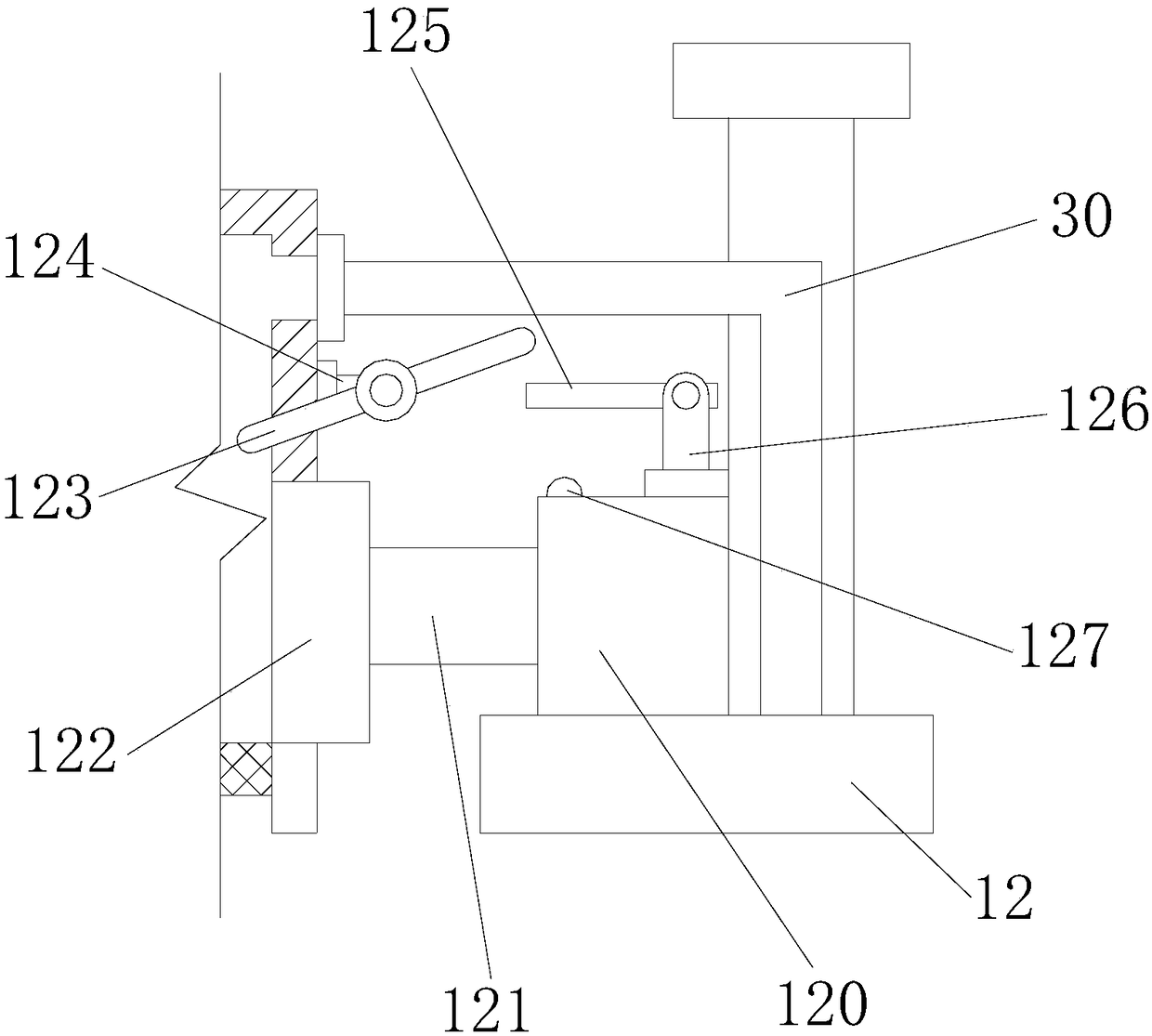

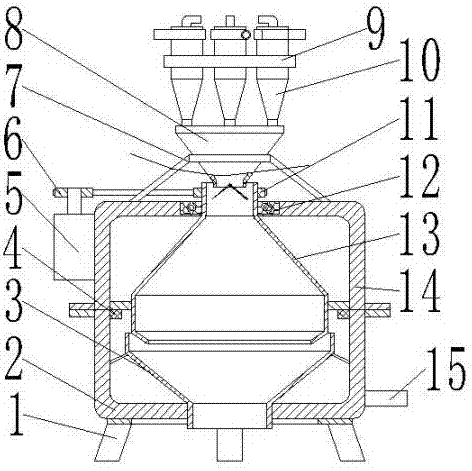

Crushing device for producing moulded coal

The invention provides a crushing device for producing moulded coal. The crushing device comprises a crushing mechanism, a vibration mechanism and a coarse material recycling mechanism. The crushing mechanism comprises a crushing machine body, a crushing motor and a scraper motor. The lower end of the crushing mechanism is provided with the vibration mechanism which is a vibration screen. The interior of the vibration screen is provided with screen cloth with the particle size being 3 mm, the upper portion of the vibration screen is provided with a coarse material outlet, and the lower portion of the vibration screen is provided with a discharge outlet. The coarse material recycling mechanism comprises a receiving hopper, an air cylinder and a telescopic rod, wherein the receiving hopper is arranged at the lower end of the coarse material outlet, and the air cylinder is arranged on a fixed rod and connected with a moving rod; the moving rod is in axial connection with the telescopic rod, and an air cylinder switch is connected to the air cylinder; and the bottom of the receiving hopper is provided with a slide plate and a slipway matched with the slide plate. The crushing device for producing the moulded coal has the beneficial effects that by arranging the coarse material recycling mechanism, not only can continuous operation of a production line be ensured, but also coarse materials can be recycled through recrushing, and coal dust can be prevented from flying through a hopper cover.

Owner:TIANJIN BEIFANG YULIANG TECH

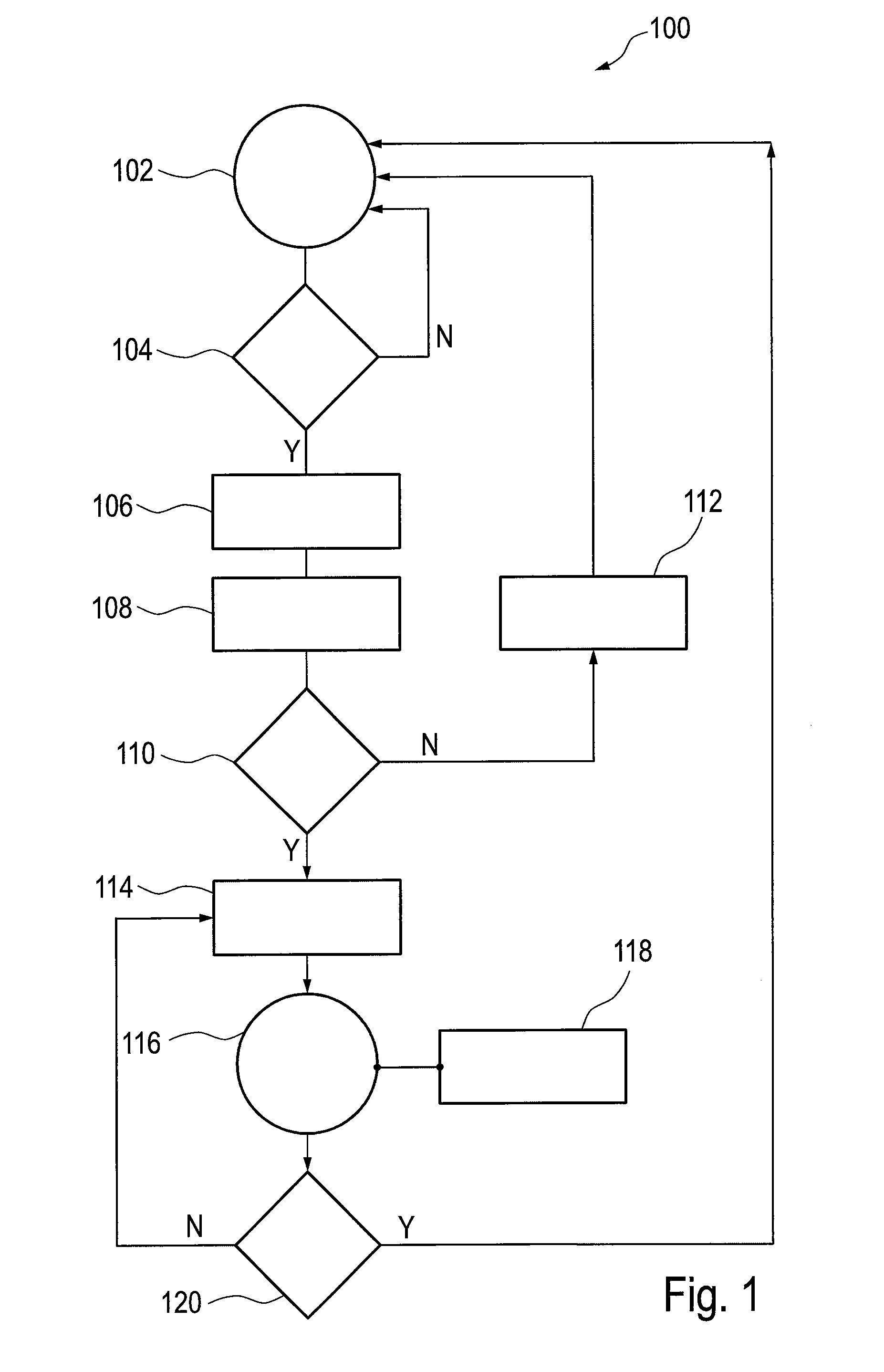

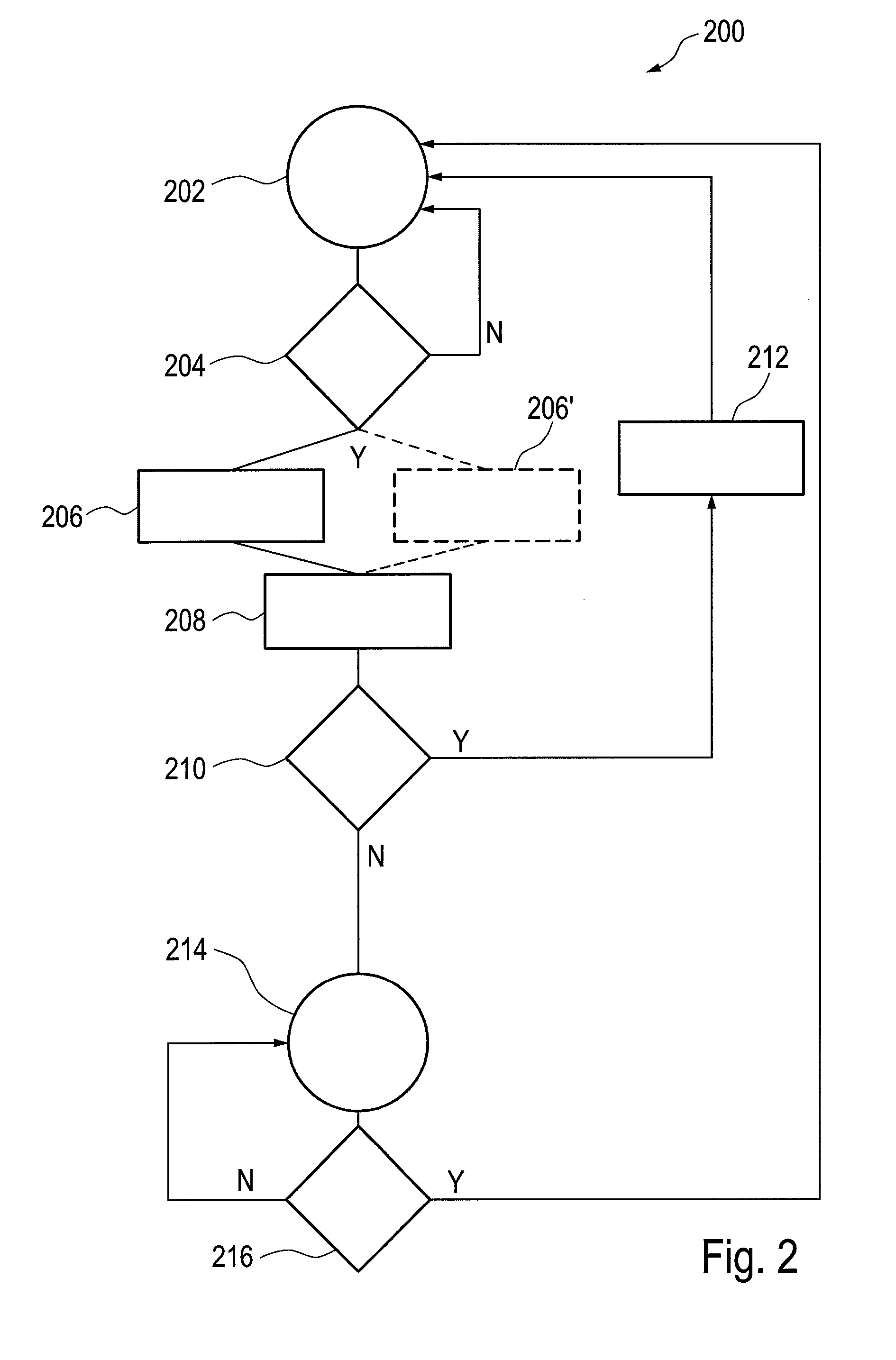

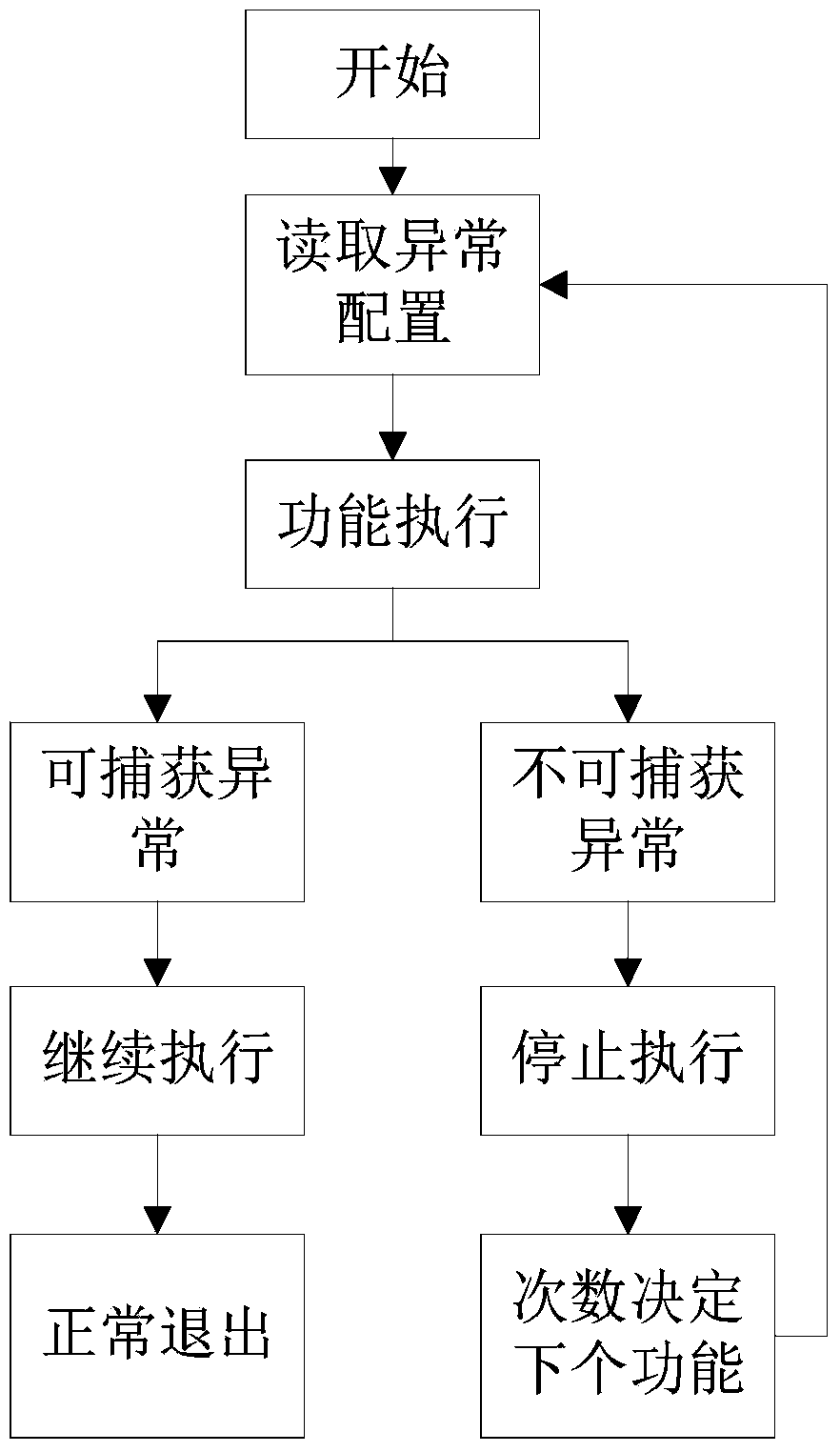

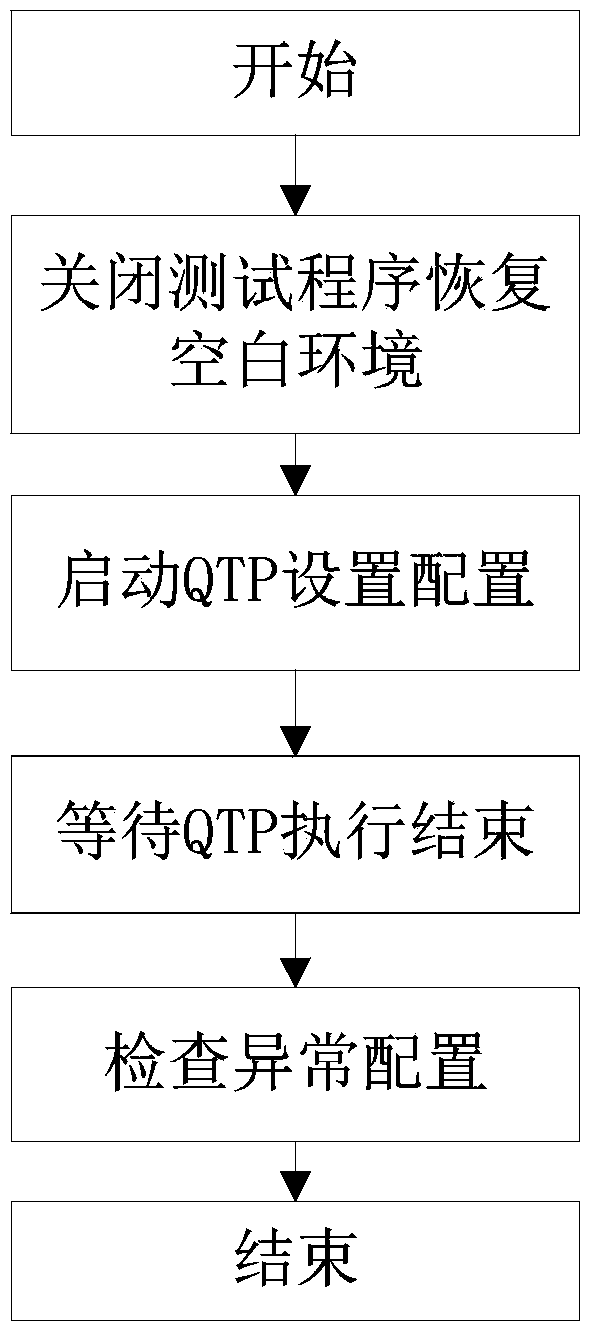

Recovery method for exceptions during automation execution

ActiveCN104239208AReduce manual maintenance workExecute tests persistentlySoftware testing/debuggingRecovery methodContinuous operation

Owner:FUJIAN XINGHAI COMM TECH

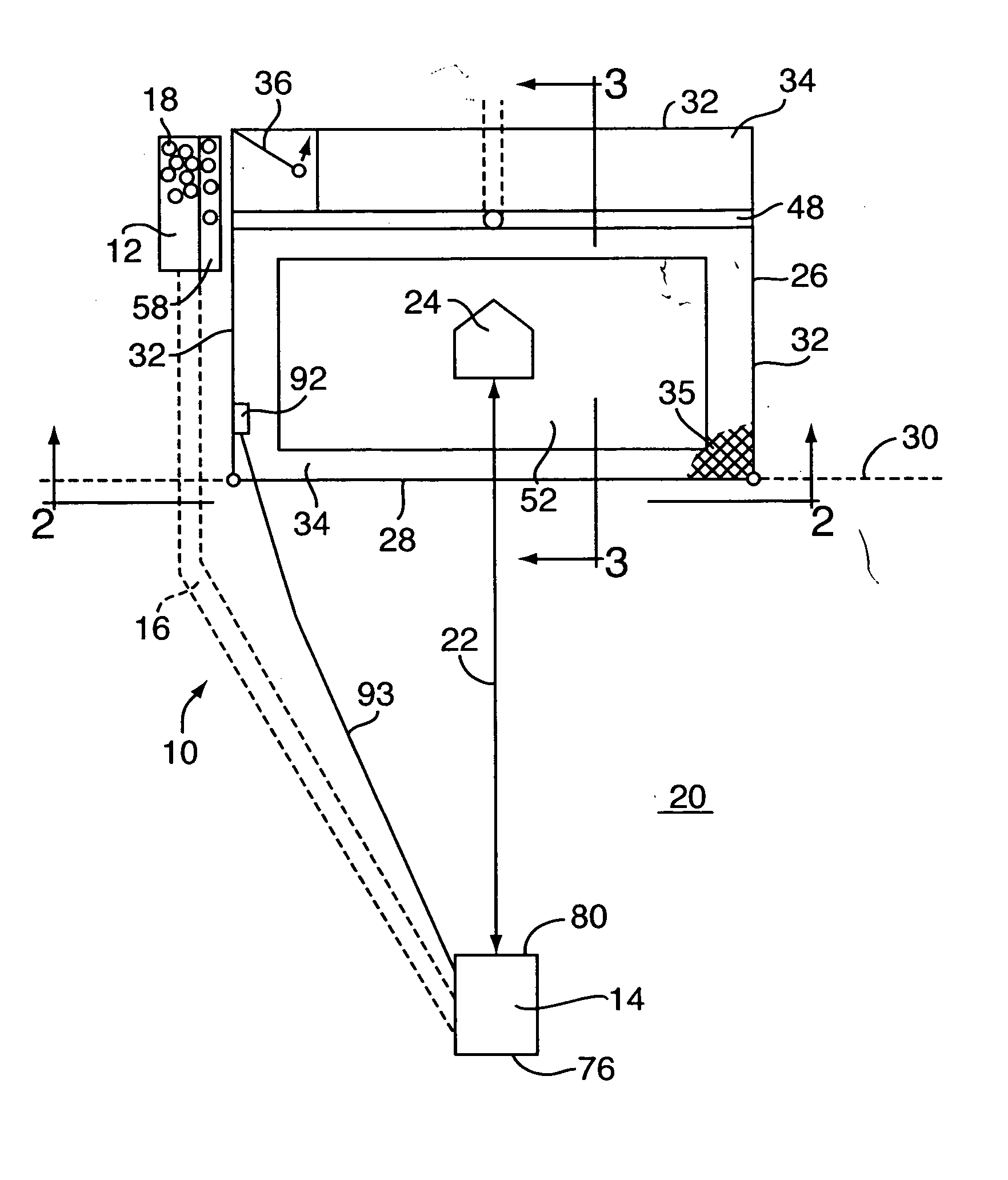

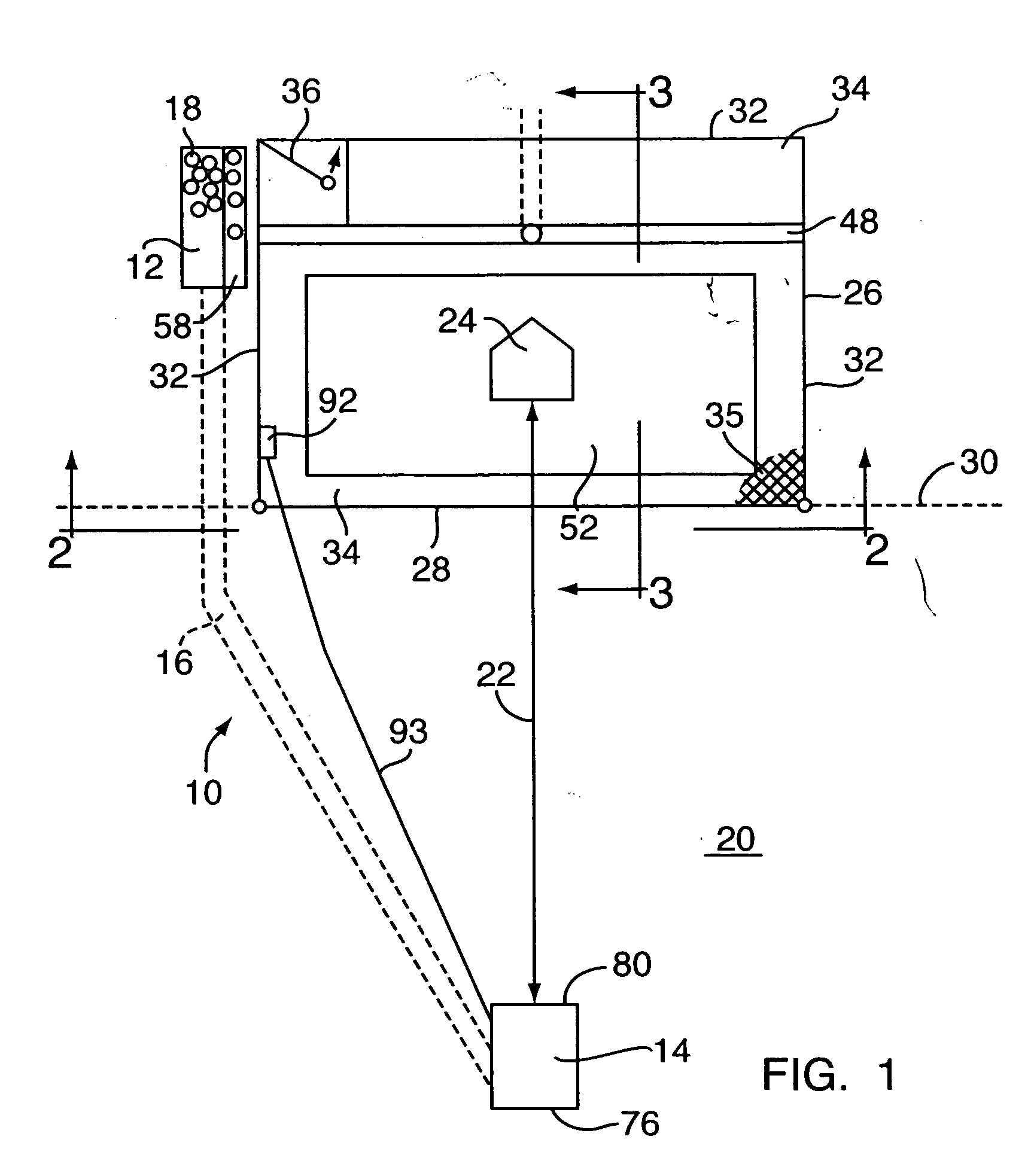

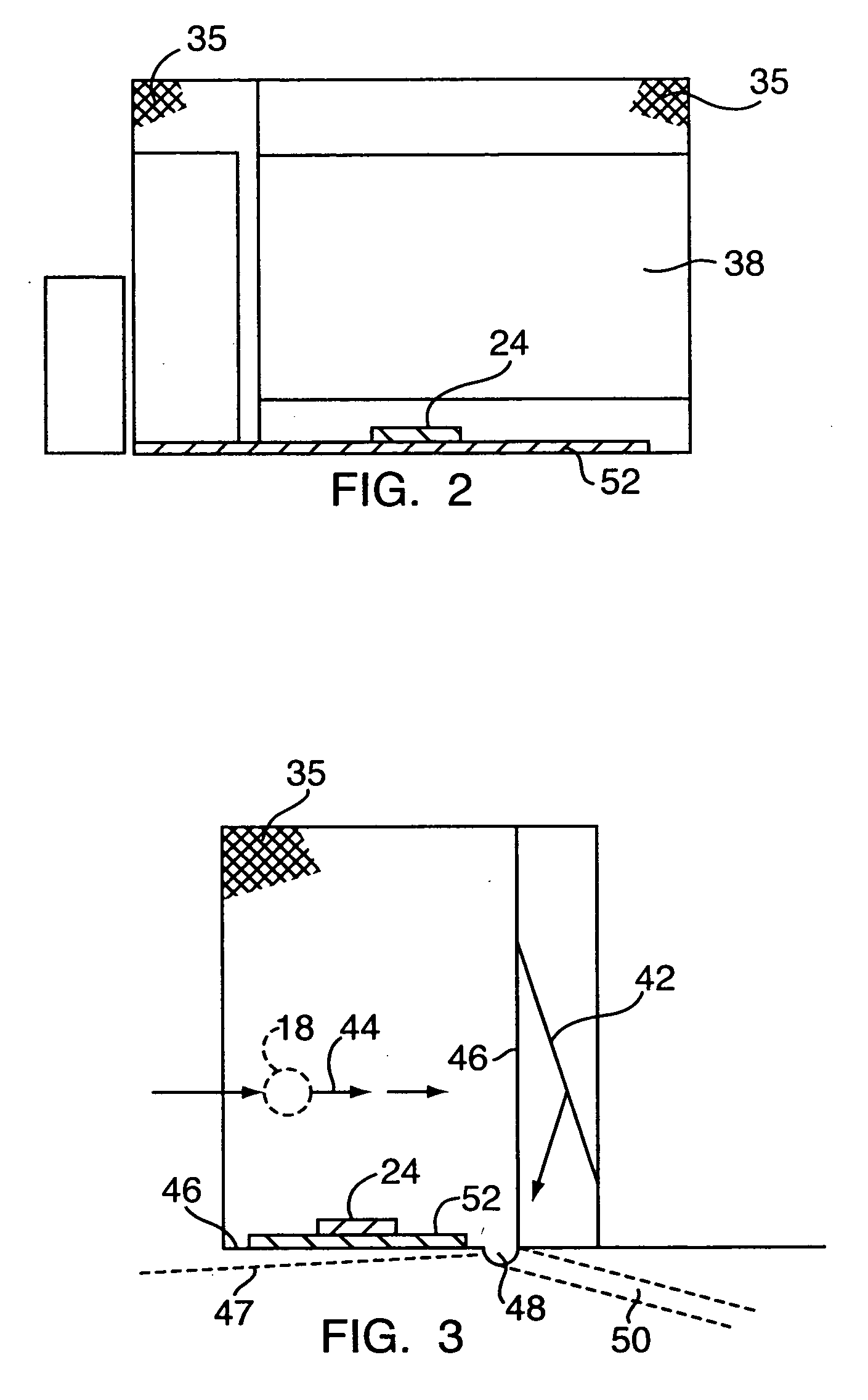

Batting system

InactiveUS20050170915A1Compressed gas gunsSolid ballsDriving rangeContinuous operation

Owner:HOLLROCK J RICHARD

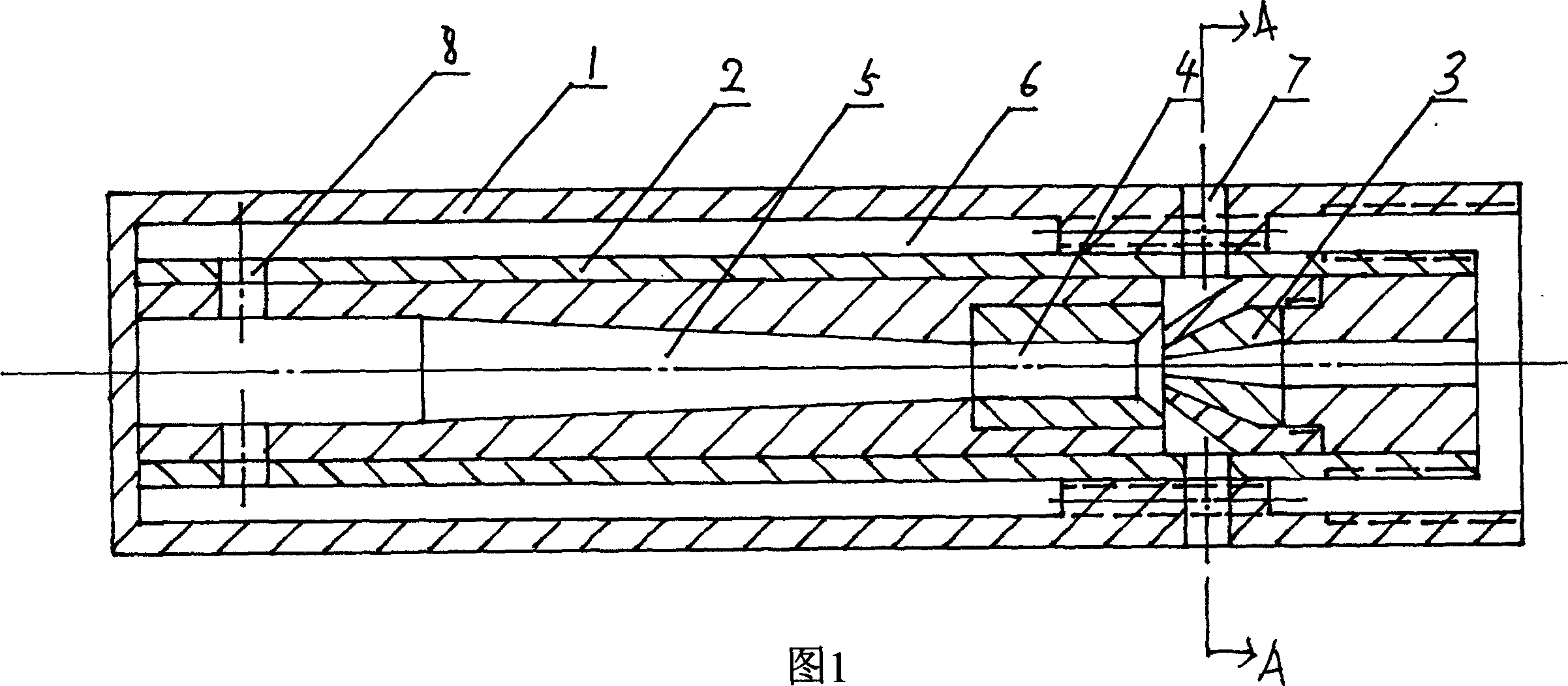

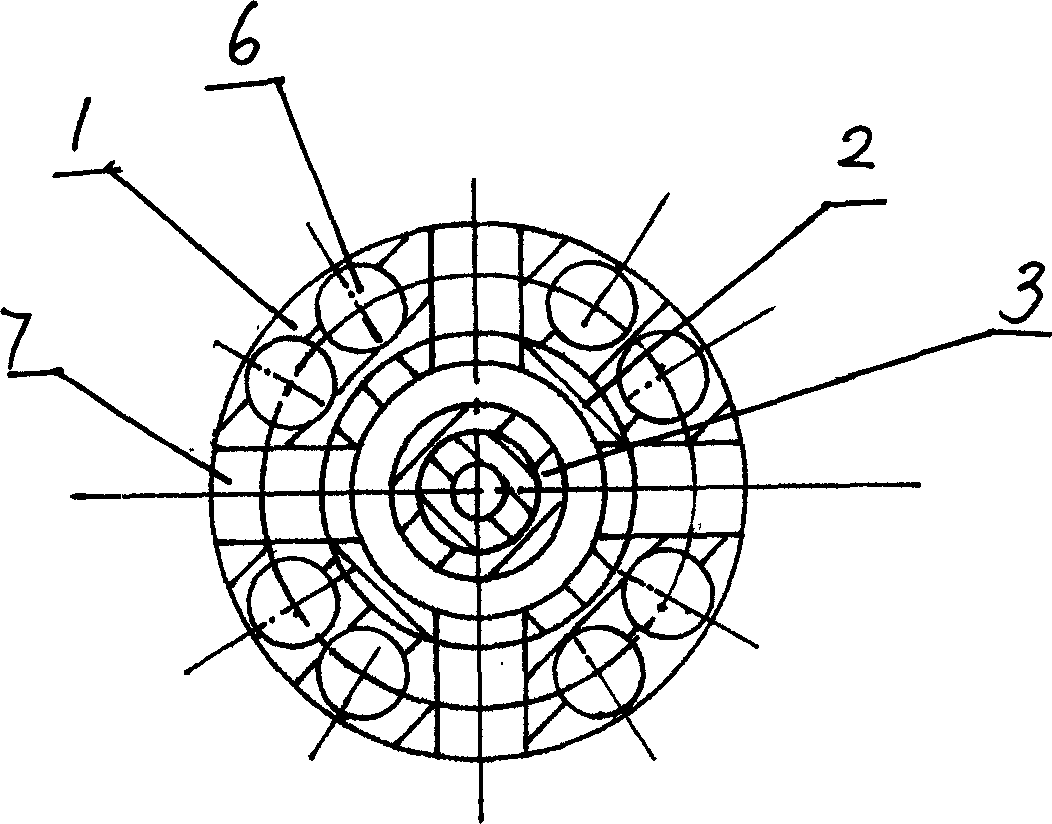

Petroleum lifting pump

InactiveCN1556333ALarge displacementDistribute slowlyJet pumpsFluid removalEngineeringContinuous operation

Owner:关建华 +1

Construction method for laying packaged concrete drainage pipelines

The invention relates to a construction method for laying concrete drainage pipes. The method comprises the following steps: (1) excavating the pipeline trench; (2) laying pipelines; (3) closed watertest for the pipelines; (4) pouring; (5) carrying out the closed water test and the pouring in sequence according to step 3 and step 4, thus completing the concrete foundation casting construction. Byutilizing the pipeline laying method, the pipeline is located and limited very well. By adopting the method of carrying out closed water test before pouring the pipelines, it overcomes the problems that the hidden trouble is difficult to be solved and the time limit is affected by the failure in continuous operation caused by the closed water test after the expiration of the concrete curing in traditional method. The two-step method utilized to pour the concrete foundation is a solution to the construction accident or quality accident caused by the traditional pouring method.

Owner:HUNAN ARCHITECTURAL DESIGN INST

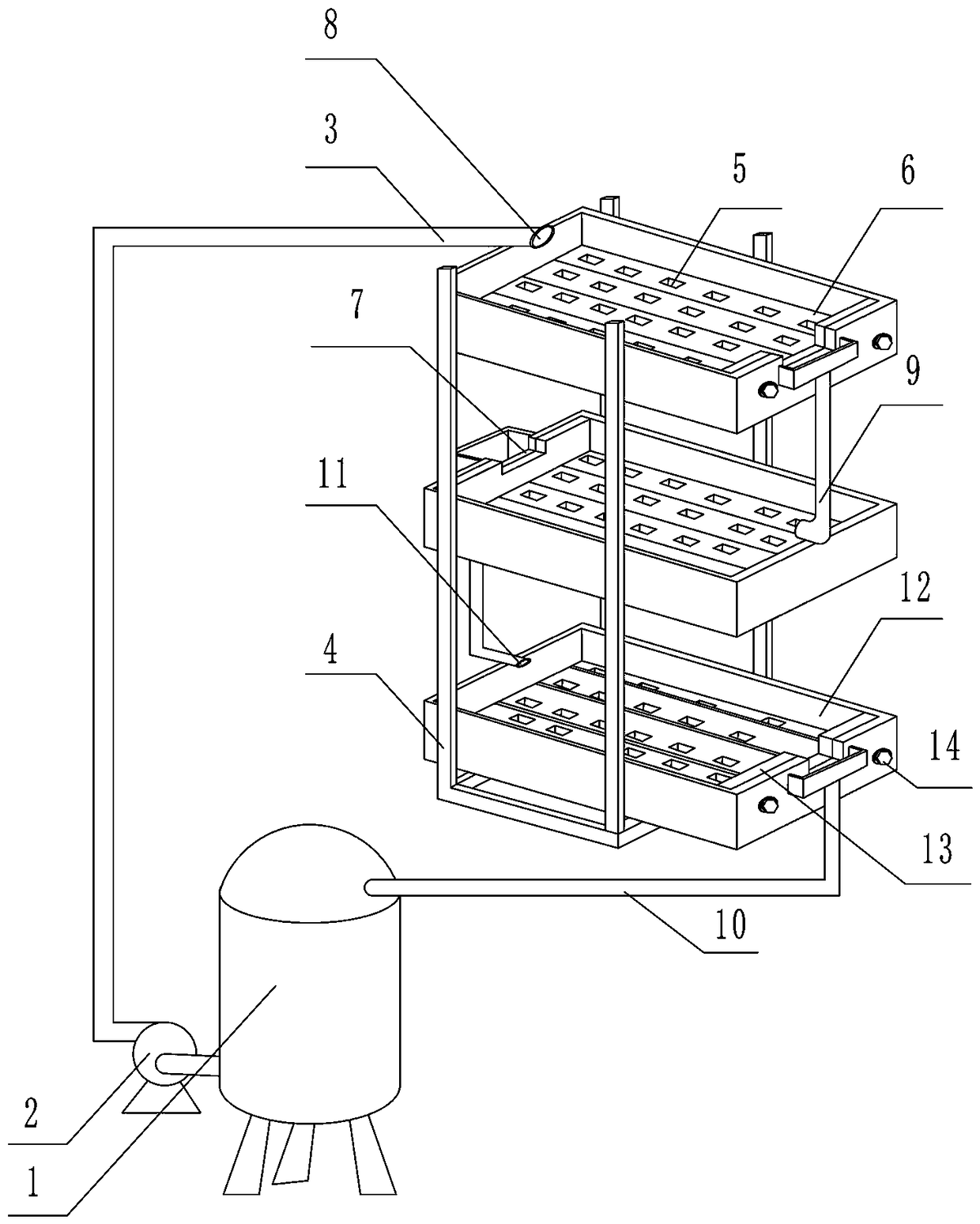

Novel straw water washing device

ActiveCN108103821ADigestersLiquid hydrocarbon mixture productionContinuous operationElectric heating

Owner:ANHUI XINDA HOME FURNISHING CO LTD

Method for forming acrylonitrile rubber drop beads on antislip gloves

InactiveCN102151649AOvercome defects such as easy peelingMeet environmental protection requirementsGlovesPretreated surfacesEngineeringContinuous operation

Owner:陈国平

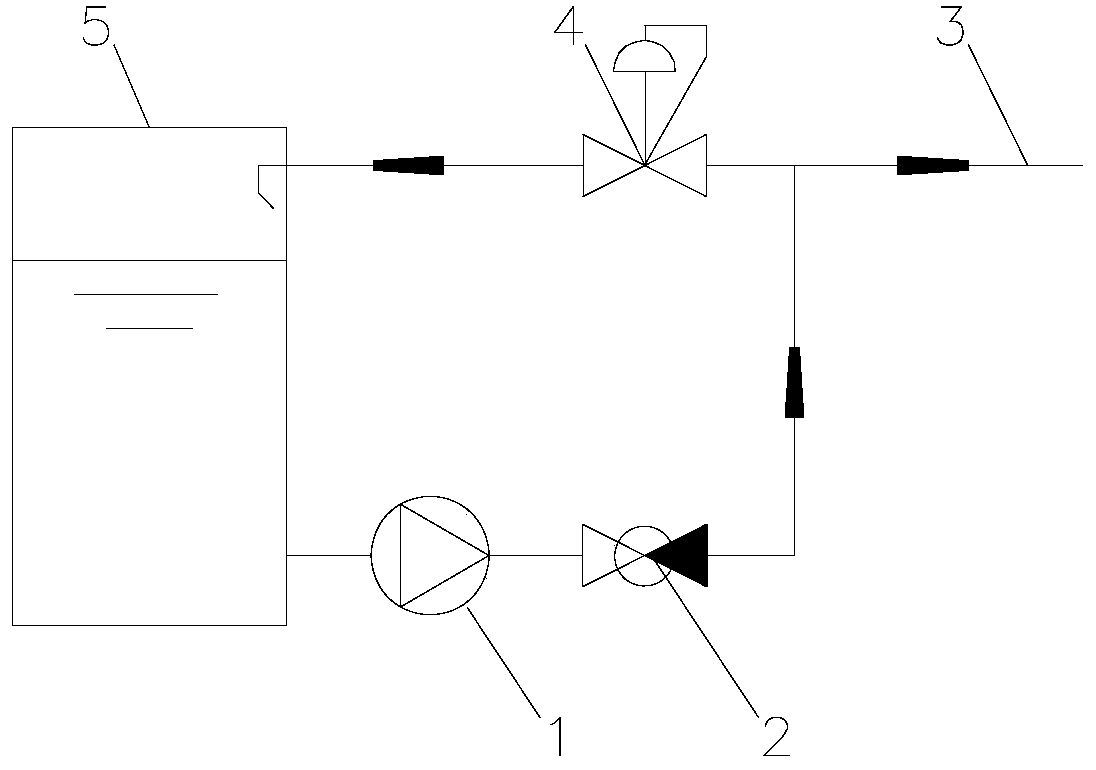

Pure pump type pressure water supply device

InactiveCN111572708AOptimize layoutReduce in quantitySelf-bailing equipments/scuppersVessel partsFrequency changerEngineering

Owner:708TH RES INST OF CSSC

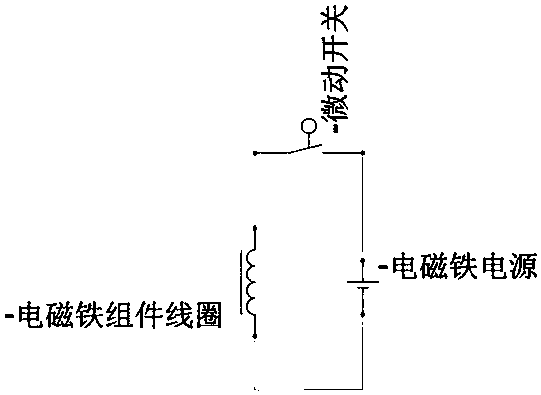

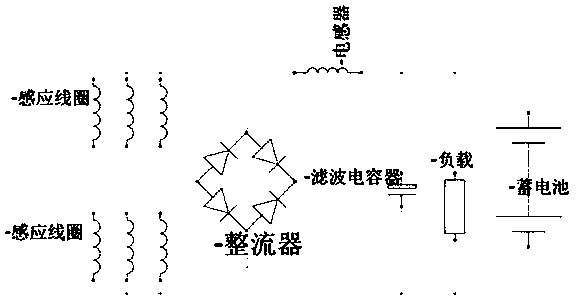

Gradient magnetic field generator

Owner:宁波聚福泰新材料科技有限公司 +1

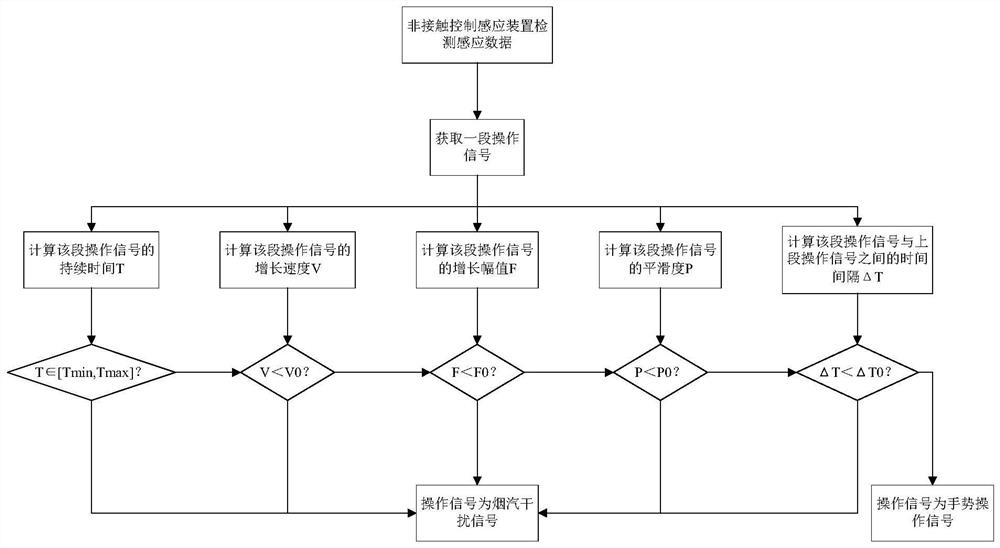

Smoke and steam interference prevention control method of non-contact control extractor hood and extractor hood

ActiveCN112728607AImprove accuracyAvoid false triggeringDomestic stoves or rangesLighting and heating apparatusThermodynamicsEngineering

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Novel high-efficiency energy-saving tailing dry-discharge equipment

InactiveCN107999270AImprove efficiencyImprove dehydration qualityDrying solid materials without heatVortex flow apparatusArchitectural engineeringContinuous operation

Owner:佛山市天宇鸿图创新科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap