Method for forming acrylonitrile rubber drop beads on antislip gloves

A molding method and nitrile rubber technology are applied to gloves, devices for coating liquid on the surface, clothing, etc., to achieve the effect of easy operation and overcoming easy peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A kind of nitrile rubber bead molding method of non-slip gloves, comprises the following steps:

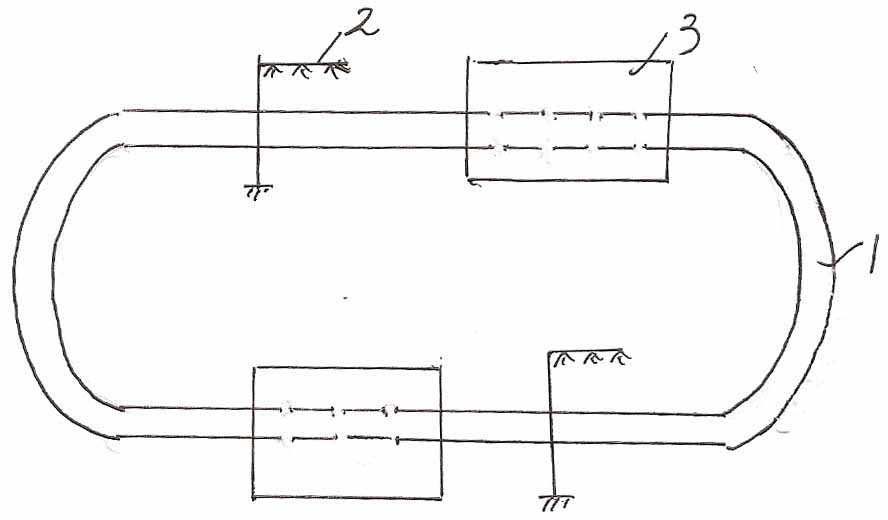

[0014] (1) The nitrile rubber bead injection device is arranged above the glove conveyor belt 1. When the glove passes through the nitrile rubber bead injection device 2, the nitrile rubber bead injection device injects the nitrile rubber bead on the glove. Nitrile beads form on gloves;

[0015] (2) The gloves injected with beads are sent to the oven 3 for drying treatment through the glove conveyor belt, and the temperature of the oven is 100~110°C;

[0016] The glove conveyor is in the shape of an oval loop and passes through the oven.

[0017] Nitrile bead injection unit can be installed above multiple stations on the glove conveyor belt.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap