Manufacturing method of plate type integrated power battery module

A technology of power battery and production method, which is applied in the direction of secondary battery manufacturing, secondary battery, multi-mode battery, etc., can solve the problems of electric vehicle development constraints, difficulty in replacement and supervision, and increase in vehicle weight, so as to facilitate long-distance Monitoring and management, long-term use without maintenance, and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0077] In order to further illustrate the technical means adopted by the present invention and its technical effects, the following describes in detail the preferred embodiments of the present invention and the accompanying drawings.

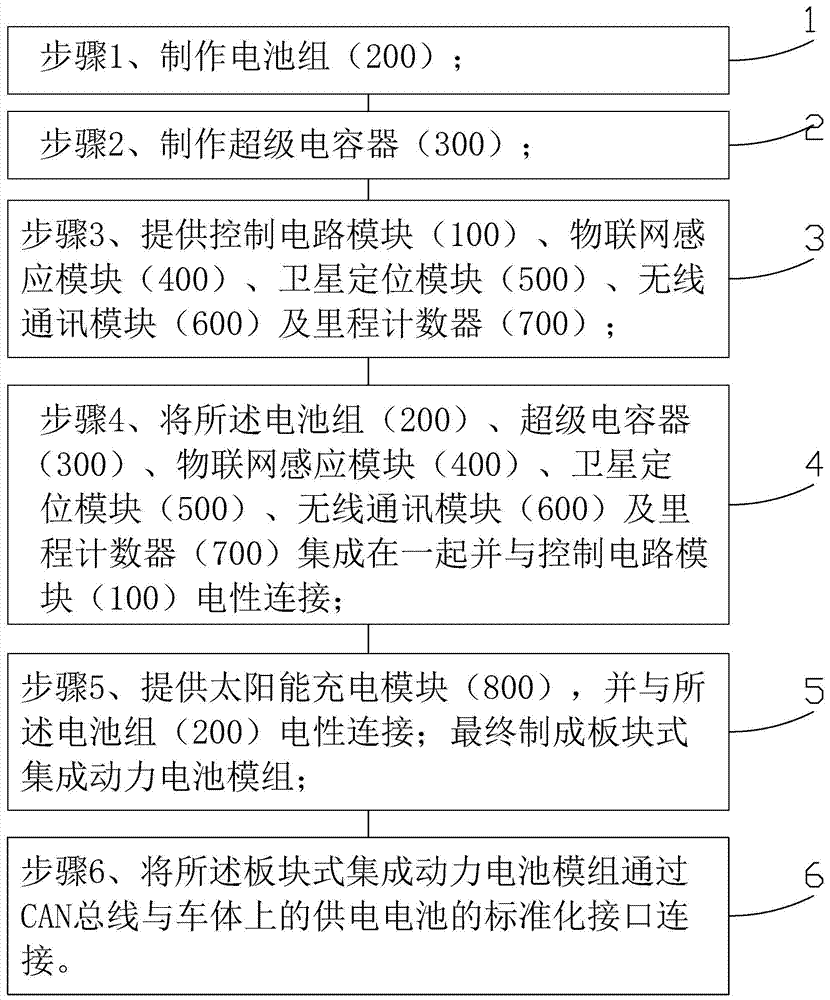

[0078] The manufacturing method of the plate-type integrated power battery module of the present invention includes the following steps:

[0079] Step 1. Make the battery pack 200.

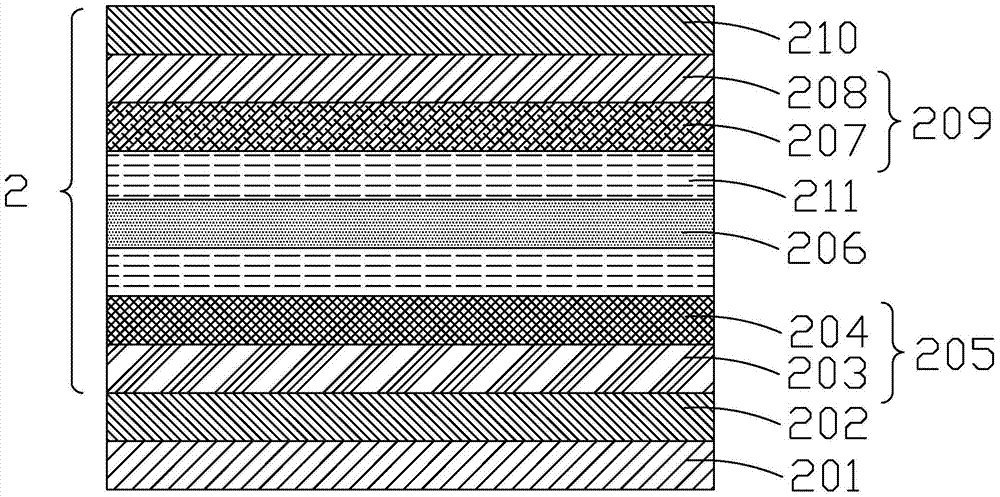

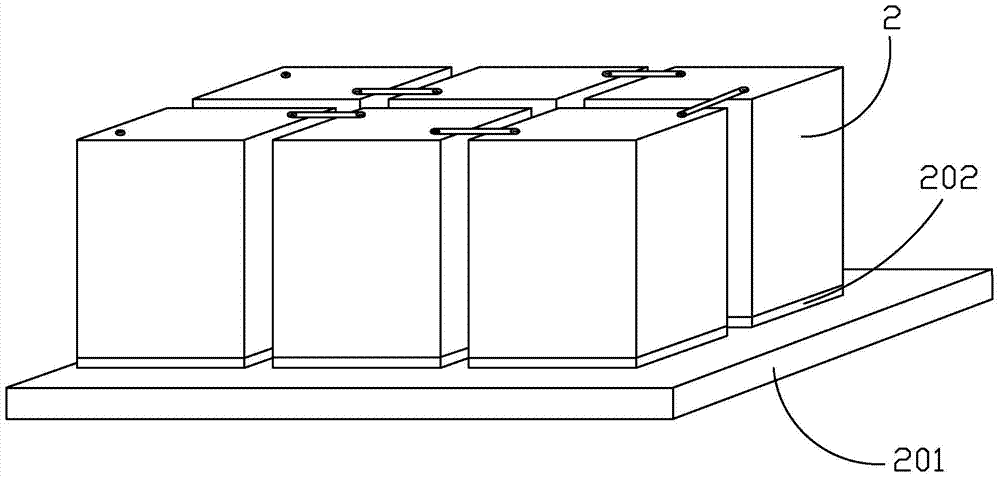

[0080] Made by figure 2 The battery cell 2 shown is composed of image 3 The steps of the battery pack 200 shown are as follows:

[0081] Step 101: Provide a flat substrate 201.

[0082] Preferably, the material of the planar substrate 201 is ceramic. In addition, metal layers are formed on both sides of the planar substrate 201 to serve as capacitors. Preferably, the metal layer is copper or aluminum. The planar substrate 201 is divided into several substrate units, and the area of each substrate unit is the area required to form a battery cell. Preferably, the thickness

PUM

| Property | Measurement | Unit |

|---|---|---|

| Withstand voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap