Sealing element, and drive unit containing a sealing element

a sealing element and drive unit technology, applied in the direction of engine sealing, gearing, toothed gearings, etc., can solve the problem of inability to achieve axial sealing between two axially adjacent components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

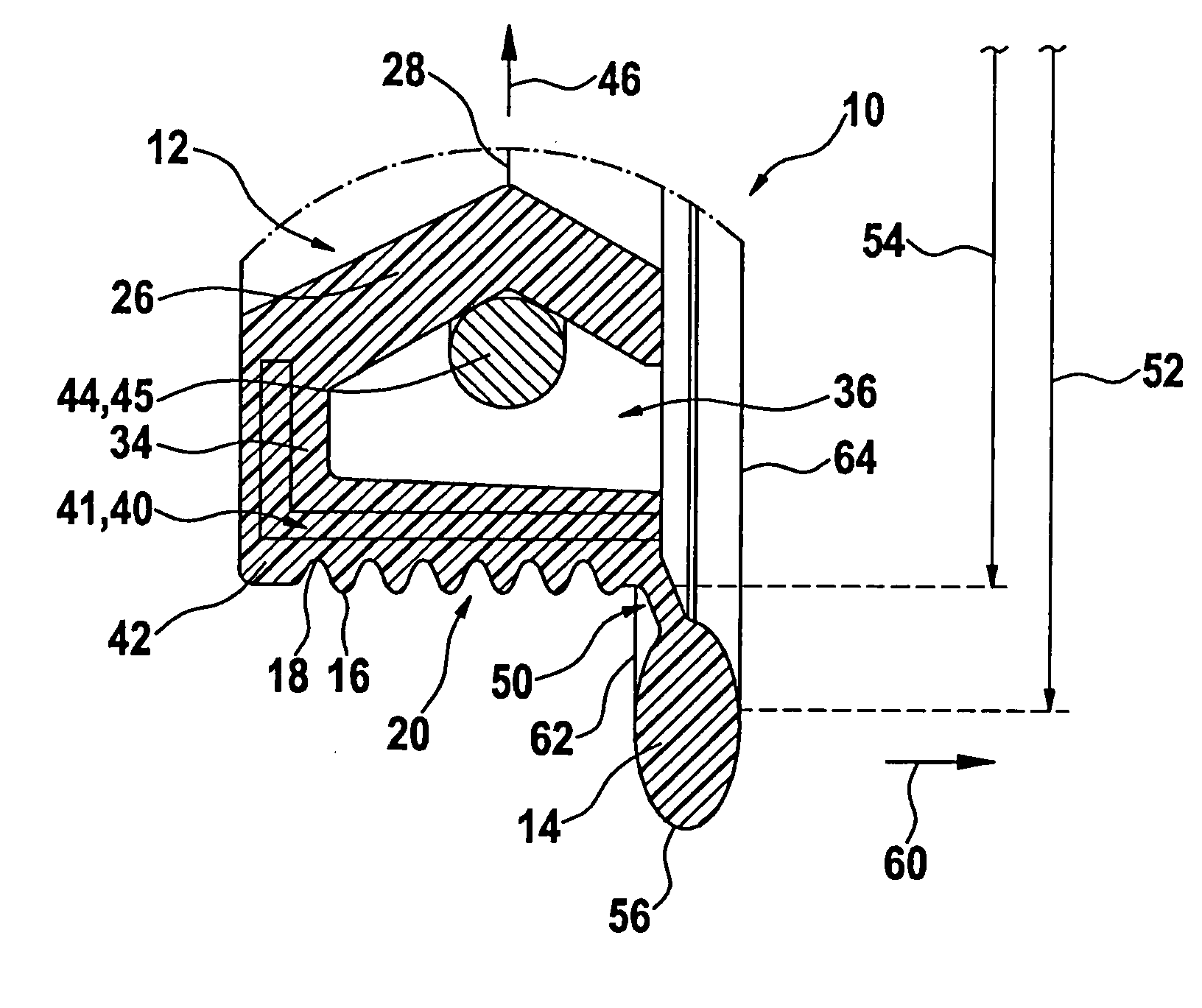

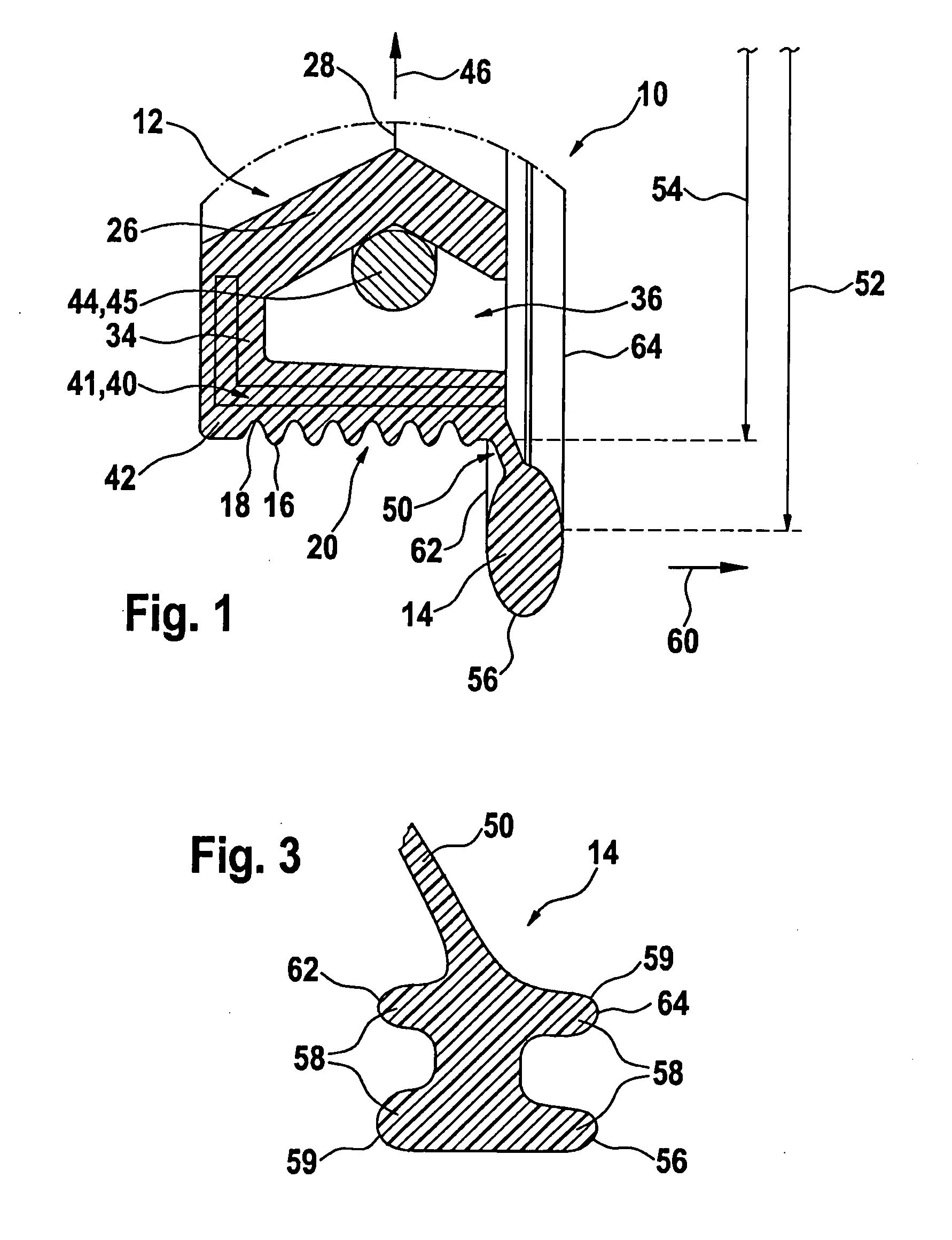

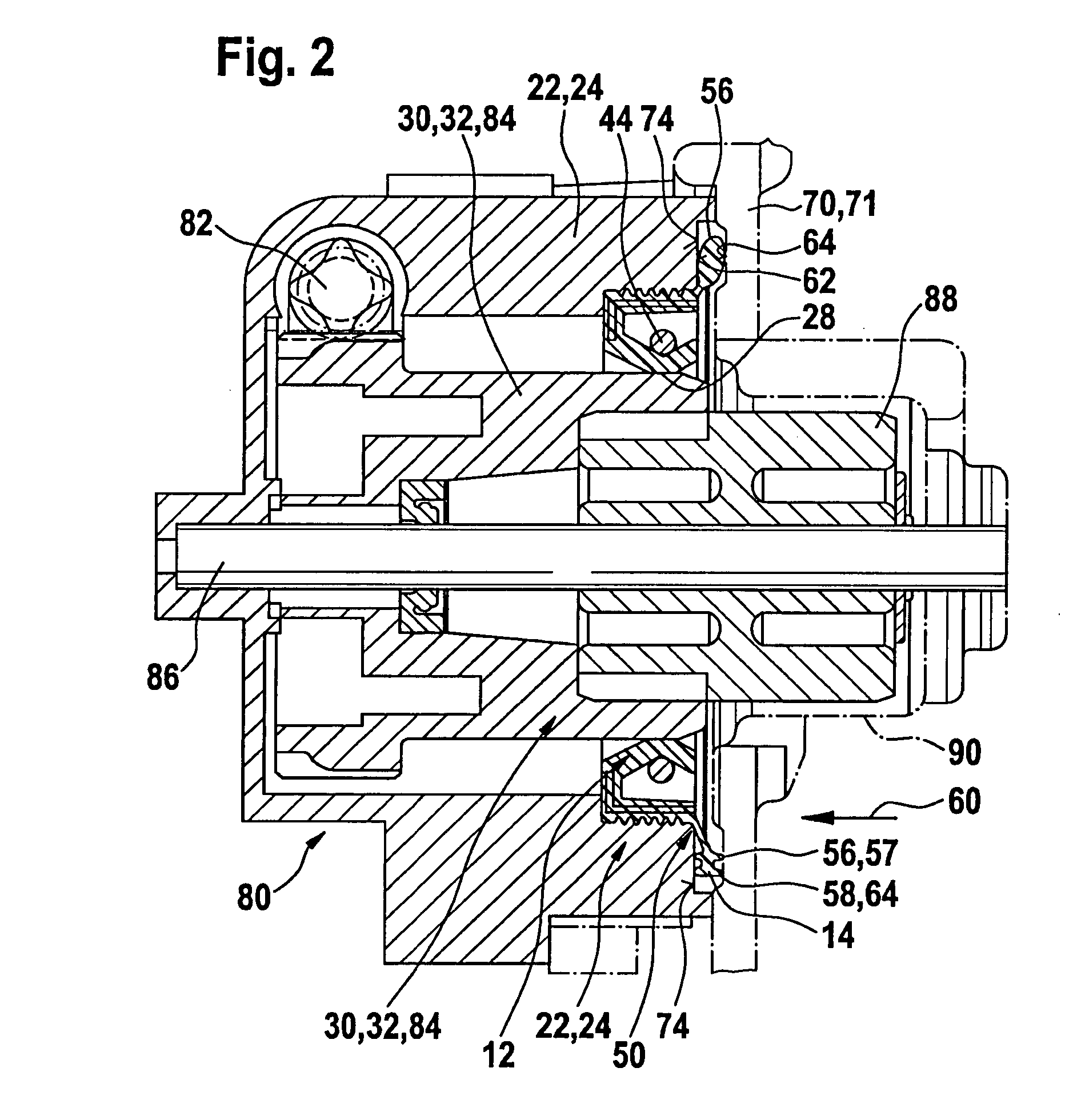

[0022] In FIG. 1, a sealing element 10 is shown, which has a radial shaft sealing ring 12 that is joined to an axial sealing ring 14. The radial shaft sealing ring 12 has a radial sealing face 16, which in the exemplary embodiment has a structuring 20 embodied as grooves 18. This structuring 20 serves to compensate for pressure peaks and for better adhesion to an outer component 22 to be radially sealed off. Diametrically opposite the outer sealing face 16, a sealing lip 26 is integrally formed onto the radial shaft sealing ring 12 and has a sealing edge 28 for radial contact with an inner component 30. The inner sealing lip 26 is joined to the outer sealing face 16 via a connecting region 34 extending in the radial direction, so that the radial shaft sealing ring 12 has a substantially U-shaped profile 36. The sealing element 10 in the exemplary embodiment is produced by means of an injection-molding process, in which a metal support ring 40, as an inlay part, is spray-coated with a s

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap