An anti-icing rainwater pipe system and working method suitable for flat roofs in the north

A working method and technology of rainwater pipes, which are applied to roof drainage, roofs using flat/curved panels, and roofs using tiles/slate tiles, etc., can solve problems such as not being found by engineers and technicians, prevent winter cracking, and significantly economical Benefits and social benefits, the effect of facilitating the promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

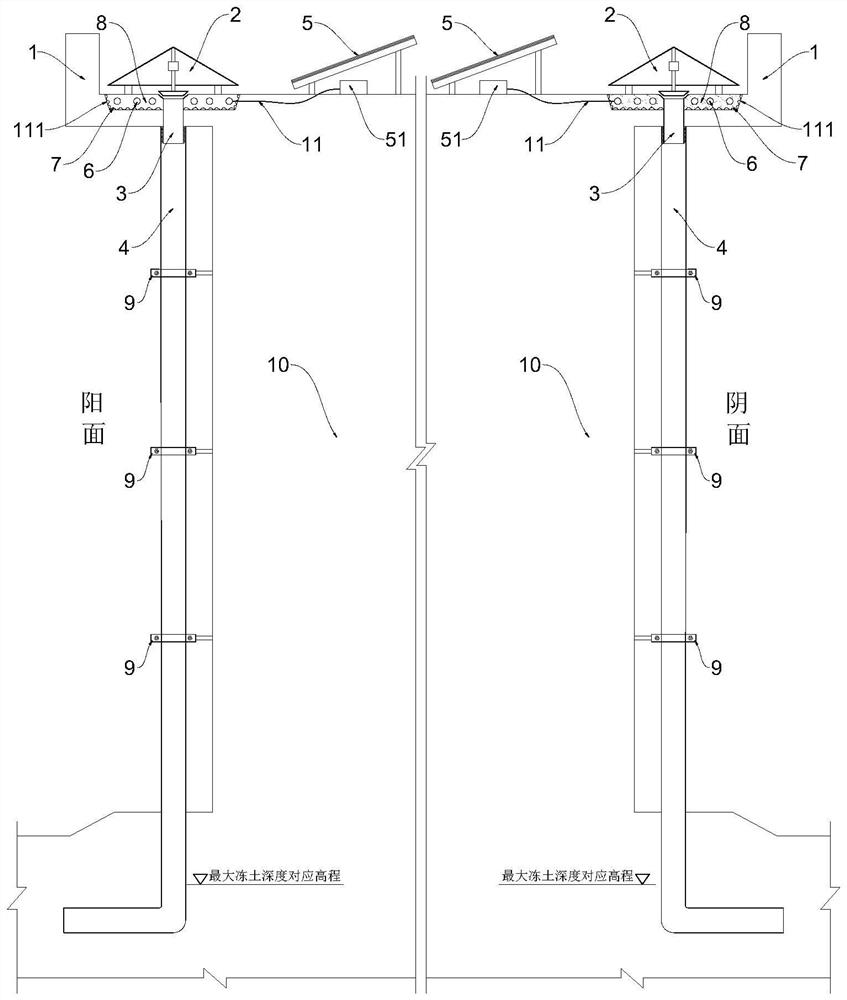

[0037] Example 1: as figure 1 As shown in the figure, the present invention can be applied not only to new buildings, but also to renovation and renovation of roof drainage systems of existing buildings. When applied to a new building, when pouring concrete on a flat roof, reserve the position of the concave mouth 111 of the combined gutters 1 in advance in the corresponding parts of the gutters, and wait until the concrete around the periphery of the concave mouth 111 is poured and hardened. After that, the solar power generation panel 5 and the attached cable 11, the power control switching device 51, etc. are installed on the flat roof. In the concave opening of the combined gutters 1, lay the thermal insulation reflection layer 7, after the laying is completed, arrange and lay the heating cables 6 with the approximate center of the 3 water inlets. Then vibrated, scraped, plastered, and calendered. After the curing of the bean stone concrete 8 is completed, the water inle...

Embodiment 2

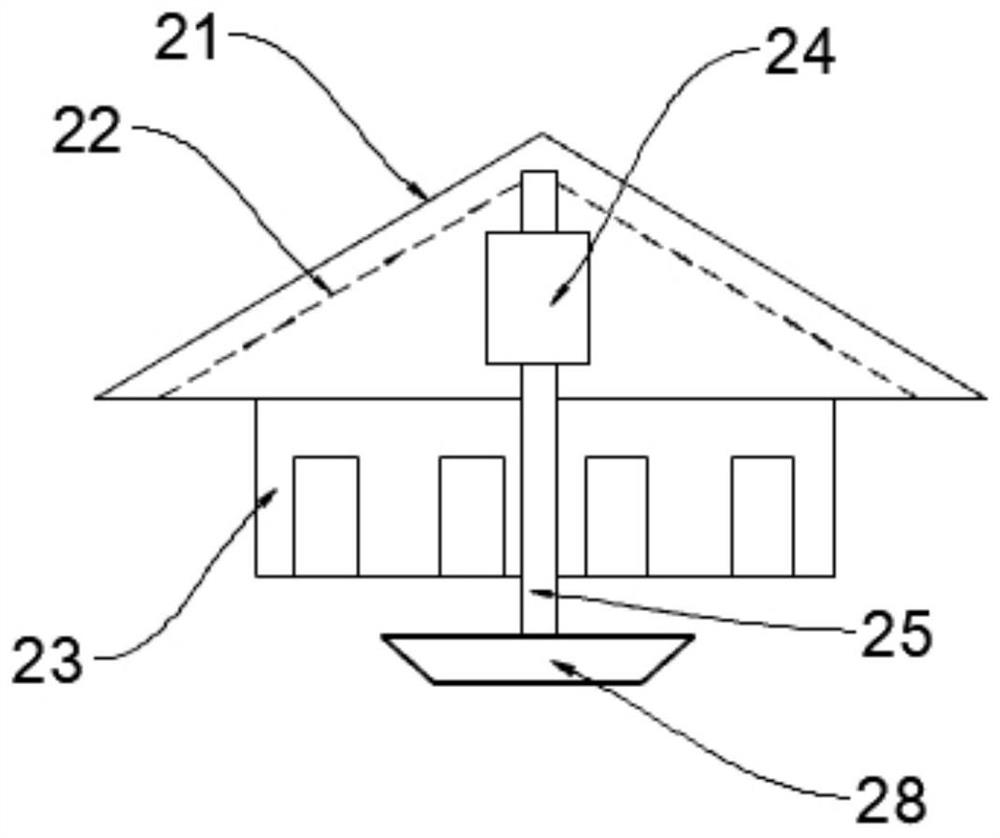

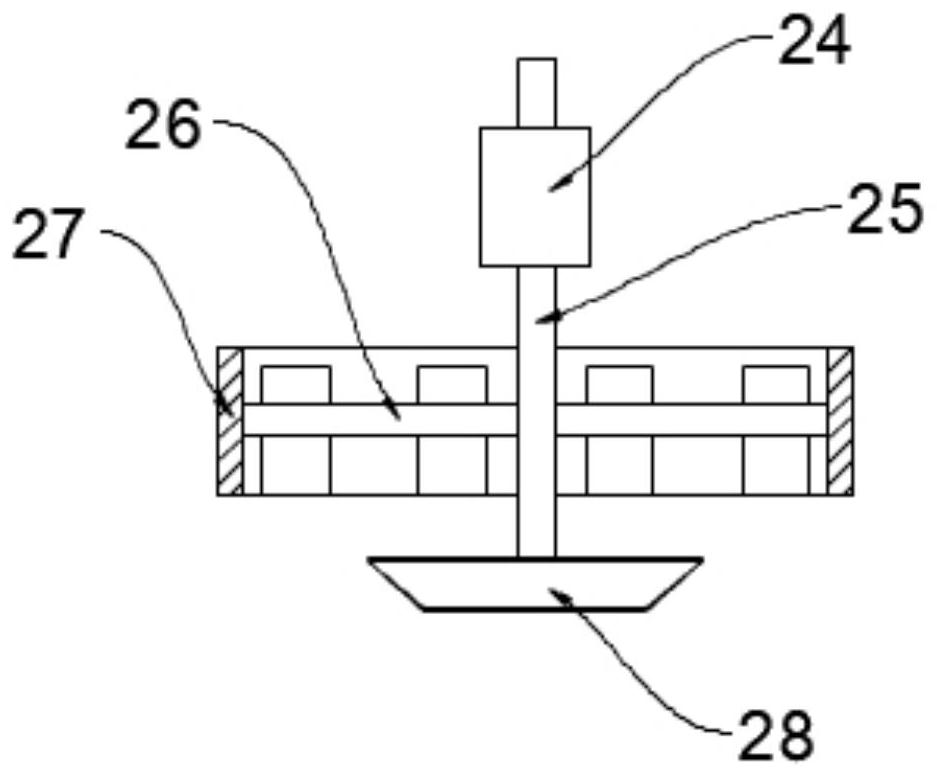

[0040] Embodiment 2: As shown in Figure 2, the shape of the water inlet protective cap 2 in the figure is a combination of a conical shape and a cylindrical shape, the outer side of the conical shape is provided with a protective cap waterproof layer 21, and the lower layer of the protective cap waterproof layer 21 is provided There is a reflective arc panel 22; the water inlet grille 23 is a cylindrical sheet-like structure, which is spaced with water inlet holes, and the inside of the water inlet grille 23 is also nested with a slightly smaller diameter, which can be passed through. The water inlet grille sealing door 27 with a cylindrical sheet-like structure is rotated by the vertical axis of the center of the circle. The water inlet sealing door 27 is spaced with water inlet holes of the same size as that on the water inlet grille 23; the water inlet protective cap 2 is vertical A lift rod 25 is arranged at the axis position, a temperature-controlled electromagnetic switch...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap