Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Good economic benefits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wellhead foam content detection sensor

ActiveCN112098338AEnable real-time analysisGood economic benefitsMaterial analysis by optical meansSurveyBattery packElectrical and Electronics engineering

Owner:SOUTHWEST PETROLEUM UNIV

Method for preparing low-zinc lanthanum chloride by utilizing multi-stage wash-extraction method

ActiveCN111041202AFlexible product adjustmentGood economic benefitsProcess efficiency improvementAnalytical chemistryAqueous solution

Owner:钢研集团稀土科技有限公司

Preparation method of nickel-based alloy powder for laser cladding

ActiveCN111014703AGood economic benefitsHigh strengthAdditive manufacturing apparatusMetallic material coating processesInert gasPhencyclone

Owner:中天上材增材制造有限公司

Quasi large-diameter pile formed by bunching plurality of small-diameter piles and construction method of quasi large-diameter pile

ActiveCN107190763AGood economic benefitsIncrease the scope of applicationBulkheads/pilesBuilding constructionEconomic benefits

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Production method for making high-grade cardboard using brush wood sheet hot grinding pulp to replace OCC (obsolescence corrugated cardboard) pulp

ActiveCN106223091AGood economic benefitsImprove economic efficiencyCellulose treatment using microorganisms/enzymesPaper-making machinesCardboardEconomic benefits

Owner:LIANSHENG PAPER IND LONGHAI

Rapid mold filling feeding and gating system for large high-temperature alloy casing casting part and pouring method

ActiveCN113787171AGood economic benefitsImprove metallurgical qualityCasting cleaning apparatusFoundry coresEngineeringFront edge

Owner:SHANGHAI JIAO TONG UNIV +1

Economizer coil hanger for narrow gaps

Owner:HARBIN BOILER

Swinging power generation device

ActiveCN107269455AExtend effective working hoursGood economic benefitsEngine componentsMachines/enginesElectric generatorElectricity

Owner:DALIAN UNIV OF TECH

Slide block elastic locking type position-adjustable chamfering device

InactiveCN104801765AEasy to useGood economic benefitsTransportation and packagingTrepanning drillsEngineeringMachine tool

Owner:SUZHOU BLUE KING MACHINE TOOL TECH CO LTD

Open-pore polyurethane rigid foam prepared from polyurethane rigid foam degradation liquid

Owner:NANJING HONGBAOLI POLYURETHANE

Device and method for detecting instability of steel-structure pressing rod

ActiveCN106093180AEnsure safetyGood economic benefitsMachine part testingMaterial magnetic variablesDistance sensorsEngineering

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Cordyceps militaris culture medium

InactiveCN107522526AGood economic benefitsGood qualityAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersAdditive ingredientBeef extract

Owner:张家港市藏联生物研究所有限公司

Hybrid power synthetic system based on magnetic gear brushless direct current motor

InactiveCN108705955AEasy to transformGood economic benefitsAssociation with control/drive circuitsElectric energy managementControl mannerControl mode

Owner:JIANGSU UNIVERSITY OF TECHNOLOGY

Integrated system for utilization of waste heat of tunnel kiln

InactiveCN103322821AEnergy savingGood economic benefitsDrying gas arrangementsWaste heat treatmentEconomic benefitsEnergy conservation

Owner:孝义市和中兴矿产有限公司

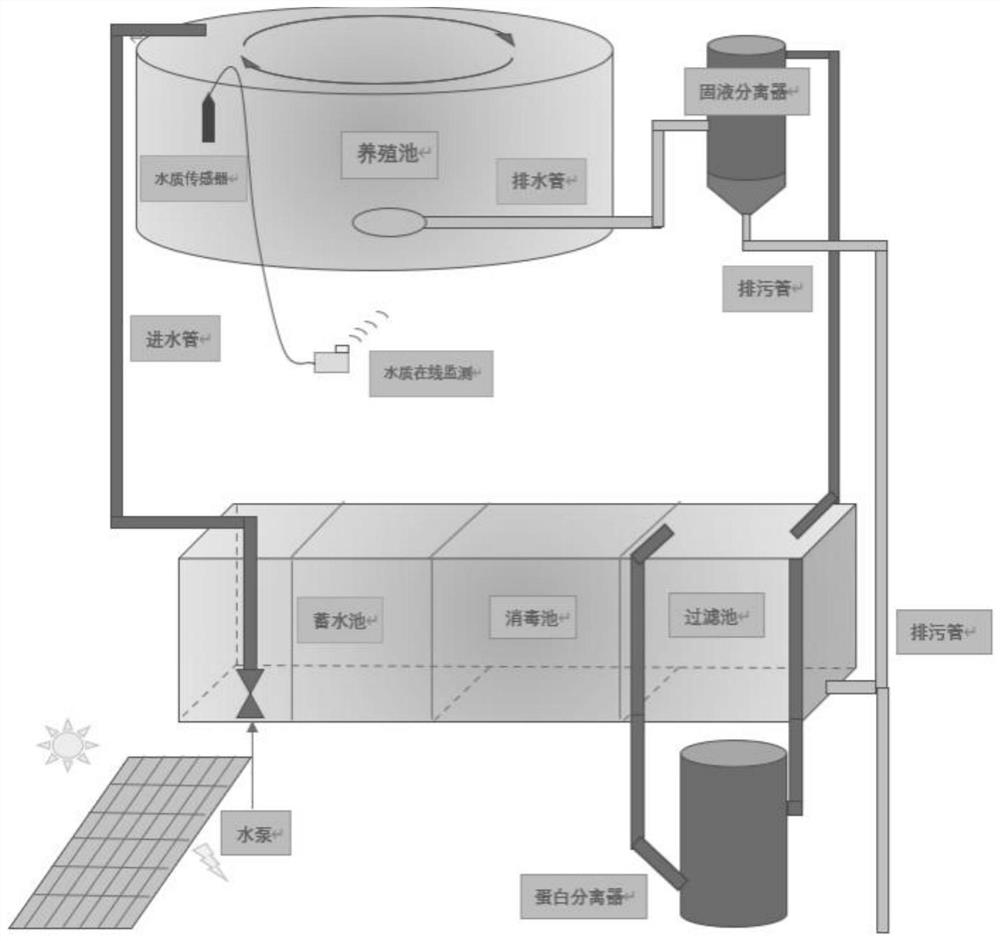

Prawn industrial culture system combining circulating water and biofloc

InactiveCN111937802AGood eco-efficiencyGood economic benefitsClimate change adaptationPisciculture and aquariaAutomatic controlBiological filter

Owner:巨大(江苏)农业科技有限公司

Cement clinker and preparation method thereof

InactiveCN110436803AGood economic benefitsHigh strengthCement productionBlended cementBuilding material

Owner:刘全富

Recovery process for crosslinked polyethylene wastes

ActiveCN105061805AEfficient and environmentally friendly recyclingGood economic benefitsPlastic recyclingCross-linked polyethyleneDepolymerization

Owner:ZHEJIANG UNIV +1

Water-based lubricant for titanium tube rolling

InactiveCN101864339AEasy to use directlyGood economic benefitsLubricant compositionAdhesiveLubricant

Owner:张岳

Low-density ceramsite proppant using industrial wastes as raw material

InactiveCN109320281AGood economic benefitsImprove use valueCeramic materials productionCeramicwareCoal chemical industryCopper

Owner:YUANQU CORUNDUM PROPPANTS

Construction method for inclined tensioning reinforcing bar type and overhanging section steel scaffold

InactiveCN103031947AGood economic benefitsSimple construction processBuilding support scaffoldsBearing capacityBuilding construction

Owner:青建集团股份公司

Novel formula of photosynthetic bacteria culture medium and preparation method

ActiveCN103898022AGood economic benefitsImprove antibacterial effectBacteriaAMINO ACID CONCENTRATEB Vitamin Family

Owner:ZHANJIANG EVERGREEN CULTURE TECH SERVICE

Rapid propagation method for cyclobalanopsis glauca tissue culture

InactiveCN106797888AGood economic benefitsGood effectHorticulture methodsPlant tissue cultureBudCulture mediums

Owner:唐春艳 +1

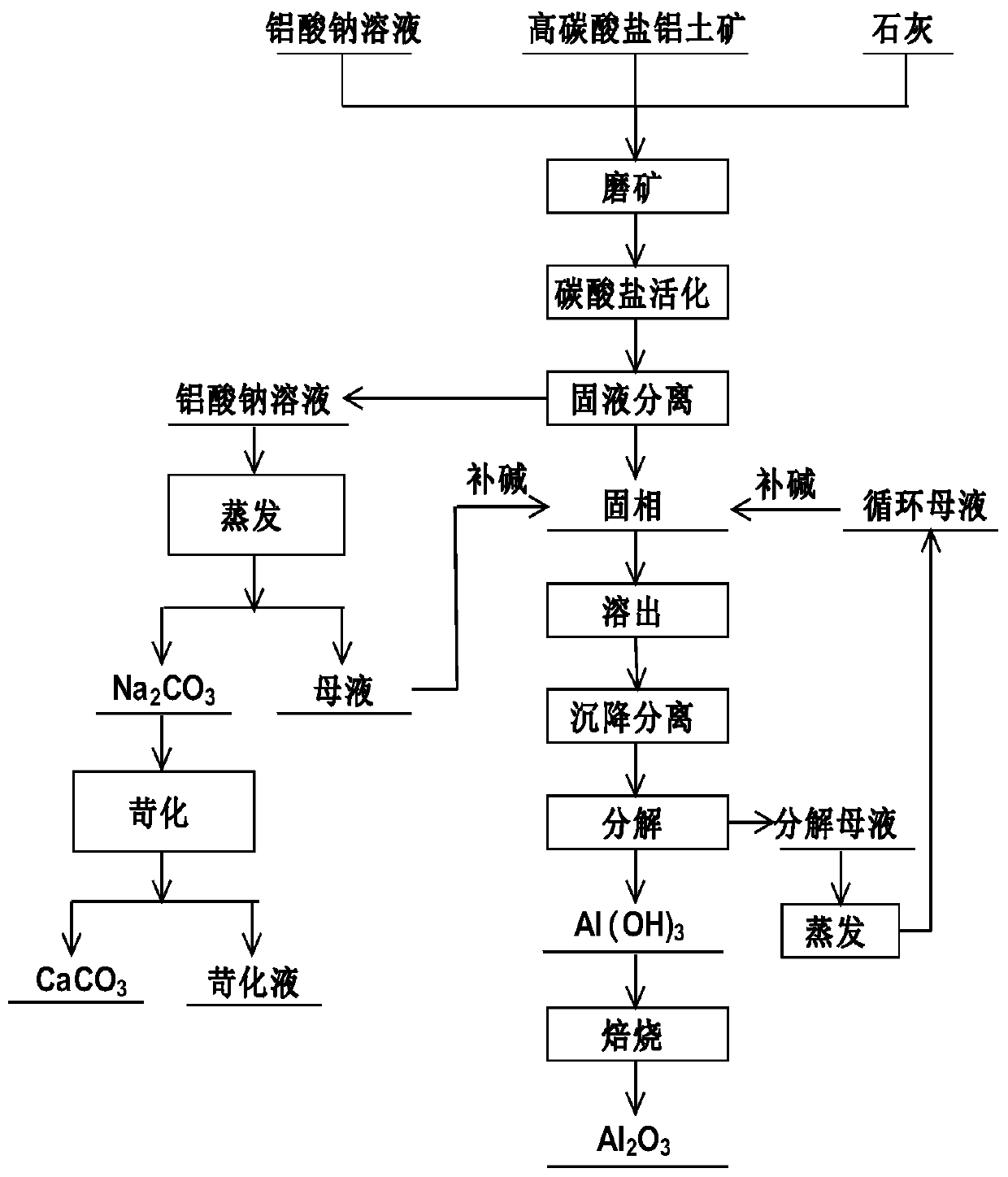

Method for producing aluminum oxide by using high-carbonate bauxite

ActiveCN110950366AGood economic benefitsReasonable processAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium hydroxideAluminium oxides

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Non-calcined desulfurized gypsum hydraulic composite gel system

InactiveCN106673574AGood economic benefitsGood mechanical propertiesBuilding materialCrystallization

Owner:TONGJI UNIV

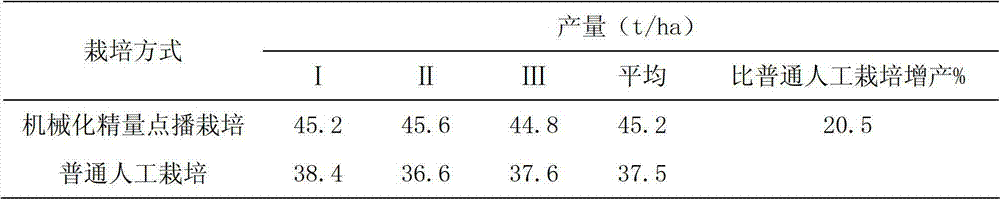

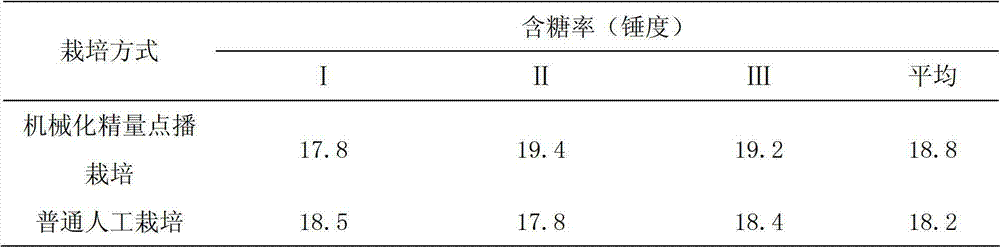

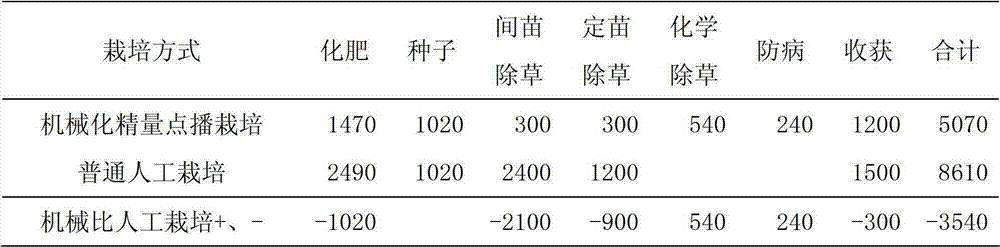

Low-cost beet mechanical precision spaced sowing cultivation method

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

Binary graphitization furnace

ActiveCN105565311AGood economic benefitsGood practical performanceEnergy inputEconomic benefitsEnergy analysis

Owner:SHANXI BEITERUI NEW ENERGY TECH

Production method of heavy alkyl benzene sulfonic acid for producing oil-displacing agent

ActiveCN104744319AGood economic benefitsImprove oil displacement effectDrilling compositionSulfonic acid preparationAlkylbenzenesAqueous solubility

Owner:江苏棋成化工有限公司

Electromagnetic wave radiation prevention PVC environment-friendly composite film material

PendingCN113022034AGood anti-electromagnetic wave and anti-radiation effectGood economic benefitsLaminationLamination ancillary operationsComposite filmEconomic benefits

Owner:GUANGZHOU PLATO PLASTIC CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap