Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Good quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

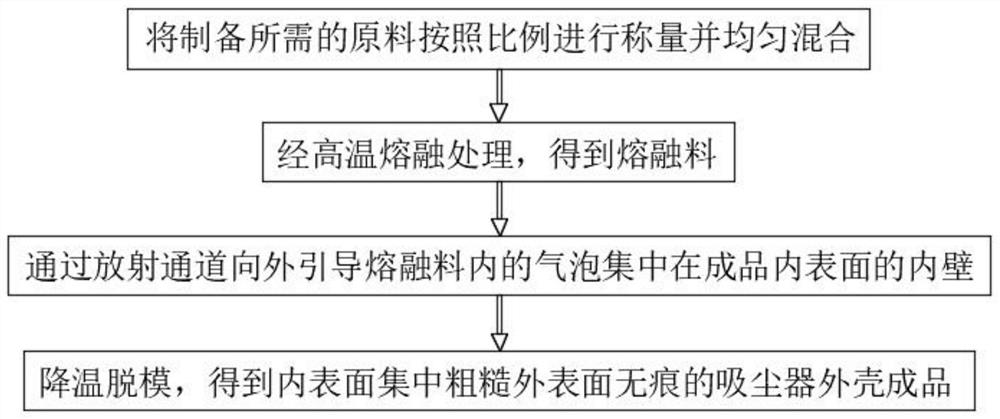

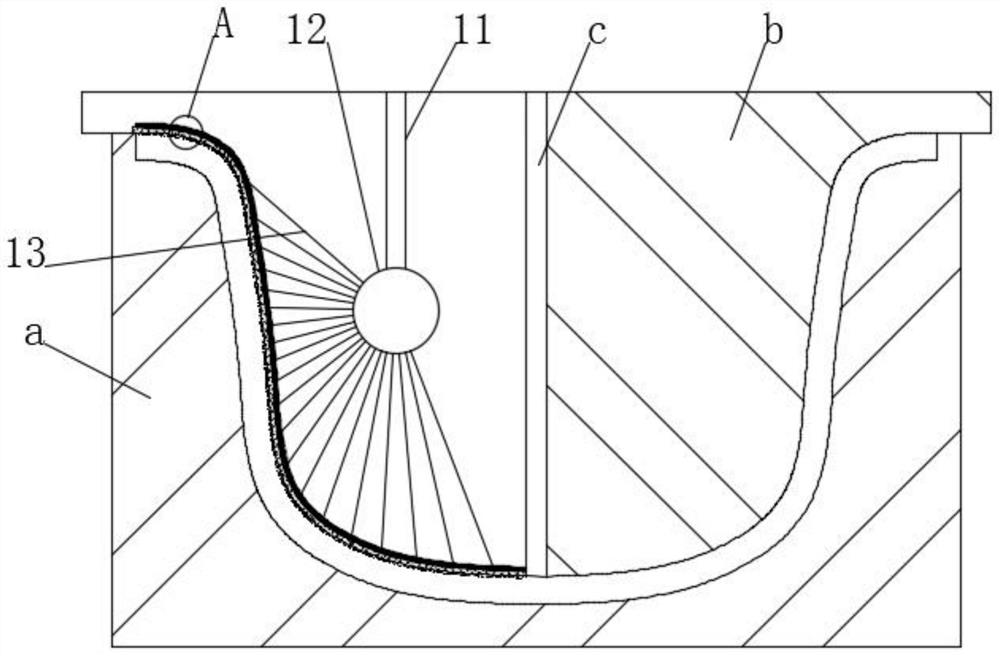

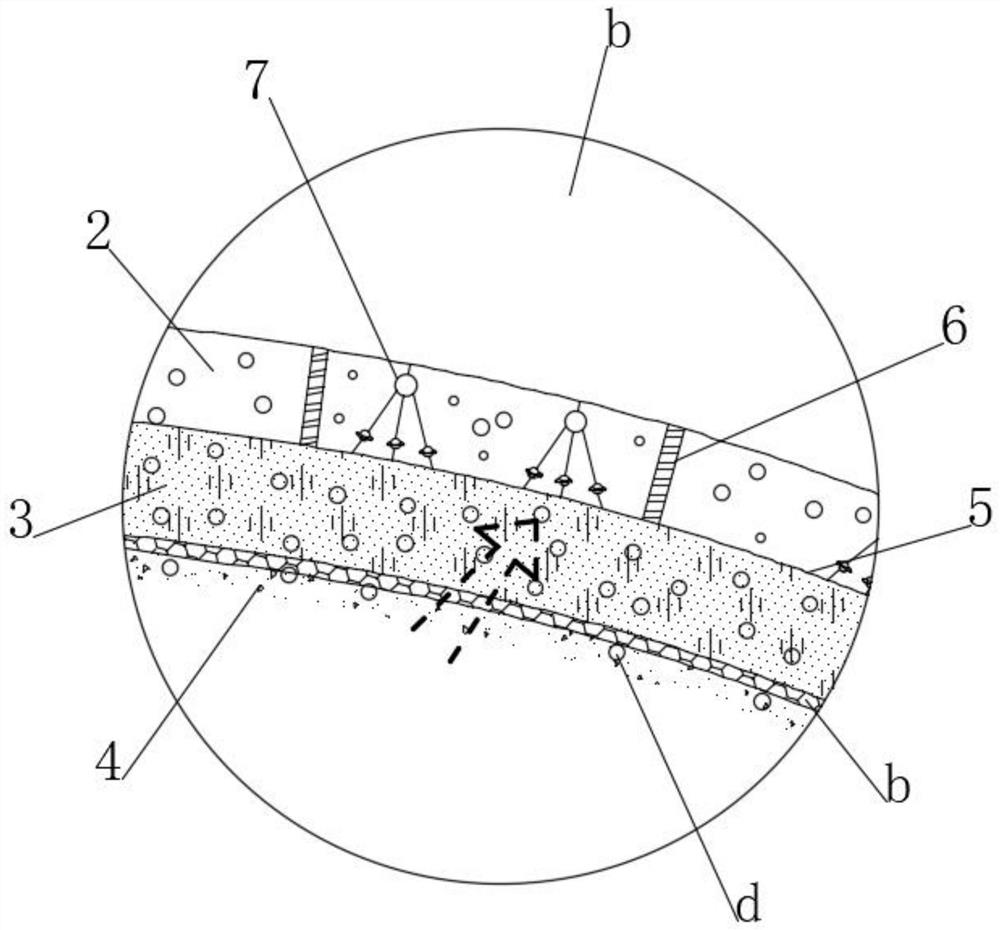

Vacuum cleaner shell soft positioning type injection molding technology

ActiveCN111645253AImprove injection molding efficiencyGood qualityCoatingsProcess engineeringManufacturing engineering

Owner:苏州博琪海电器有限公司

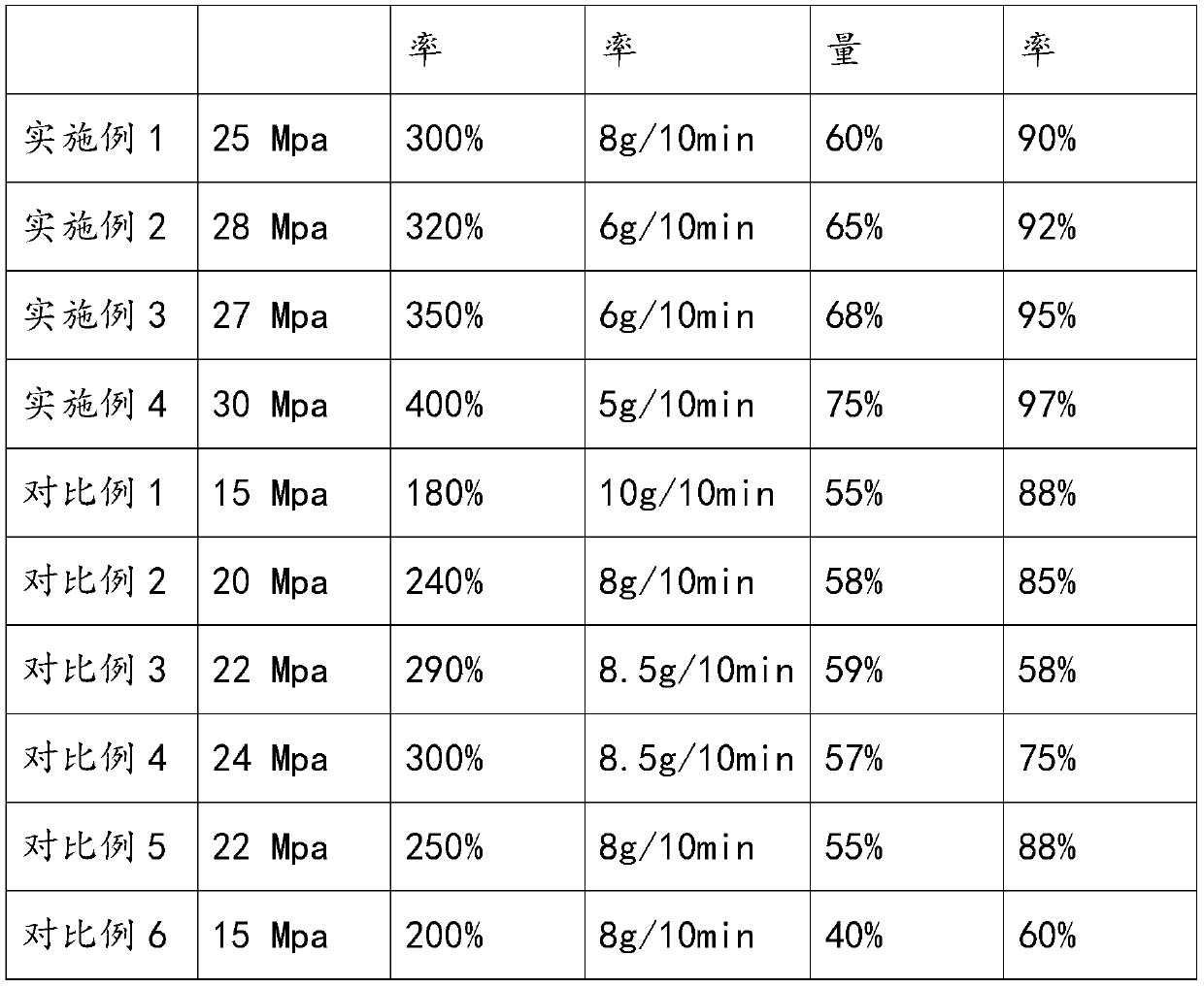

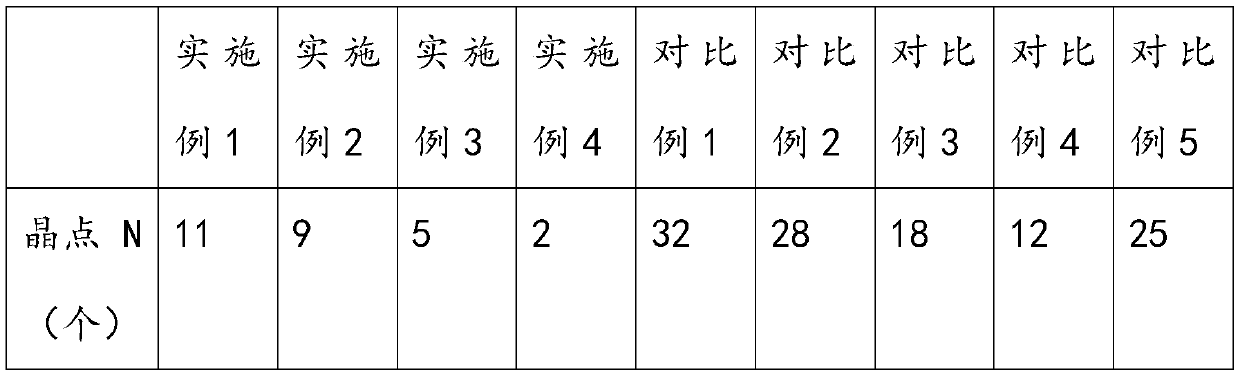

Biodegradable modified material and preparation method thereof

Owner:深圳市萤火生态科技有限公司

Production method for simultaneously preparing metal manganese and manganese dioxide in ion exchange membrane electrolytic method

PendingCN109112569AGood qualityHigh purityOrganic diaphragmsPhotography auxillary processesBuffering agentCathode

Owner:LANZHOU JIAOTONG UNIV

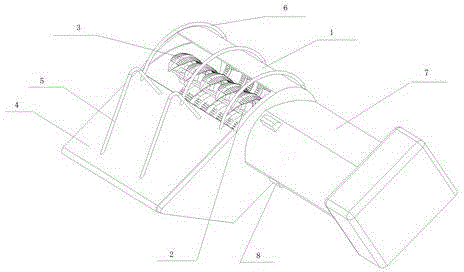

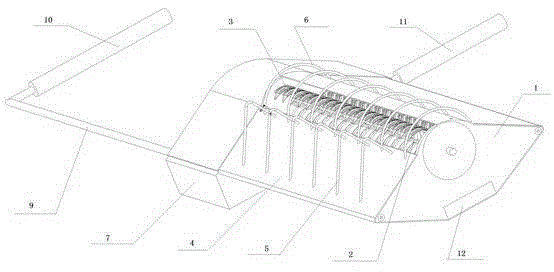

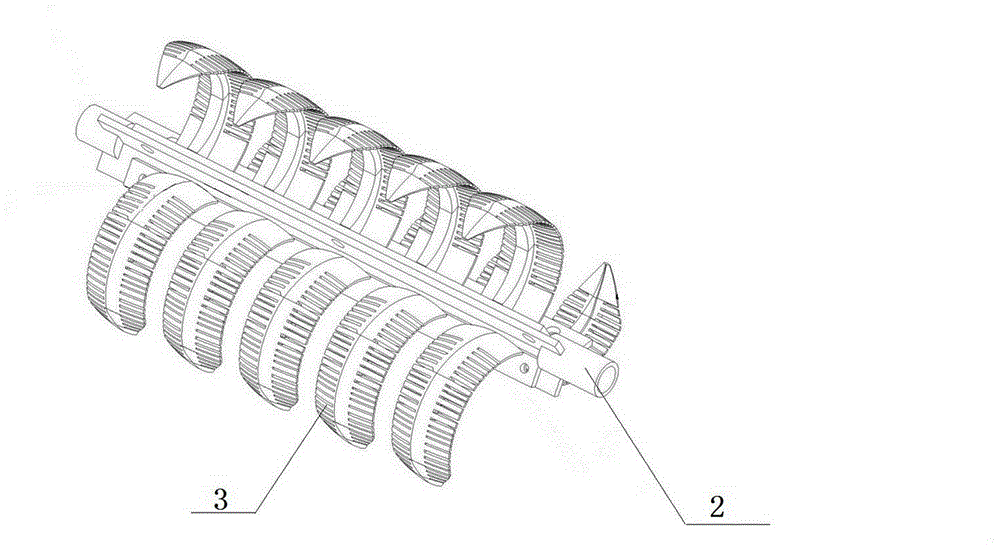

Hand-held rake-like machine for wolfberry plucking

Owner:新疆爱克斯智能科技有限公司

Hardware shell rubber jacket coating device and method

Owner:SUZHOU ZHIRUI PHOTOELECTRIC MATERIAL TECH CO LTD

Dewaxing casting system and casting process

Owner:上海琉璃工房琉璃艺术品有限公司

Wool and rabbit fur coat

The invention discloses a wool and rabbit fur coat. Warps of the wool and rabbit fur coat are pure cashmere yarns smaller than 1.0% in roving ratio, while wefts are composite wool yarns formed by blending wool fiber and milk protein fiber according to a mass ratio of 10:1-10:3. The wool fiber is 18-22 micrometers in fineness and 22-25mm in length. The milk protein fiber is 25-32 micrometers in fineness and 33-38mm in length. The wool and rabbit fur coat is fine in quality, light and soft with no hair slip, and antistatic.

Owner:KUNSHAN CITY ZHOUSHI FEIHUANG GARMENT FACTORY

Method for producing low-melting-point renewable polyester for sheath-core polyester through glycol degradation

ActiveCN103145957AGood qualityIncrease added valueConjugated synthetic polymer artificial filamentsFilament/thread formingAdipic acidAntimony trioxide

Owner:余姚大发化纤有限公司

Rutin extraction method

InactiveCN106749454AExtraction cycle shortenedGood qualitySugar derivativesSugar derivatives preparationBoraxCentrifugation

Owner:衡阳市骏杰化工有限公司

Cordyceps militaris culture medium

InactiveCN107522526AGood economic benefitsGood qualityAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersAdditive ingredientBeef extract

Owner:张家港市藏联生物研究所有限公司

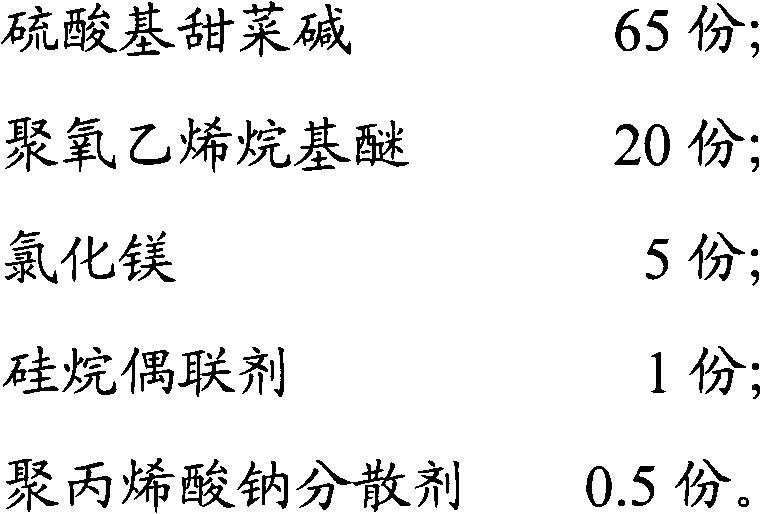

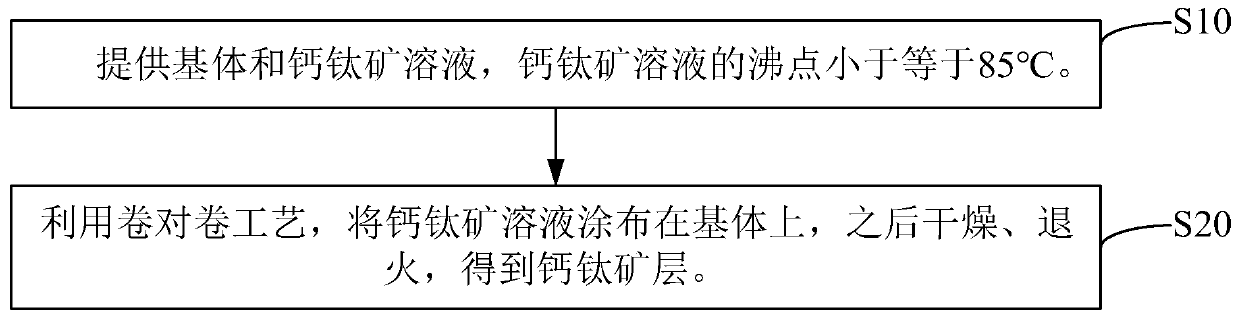

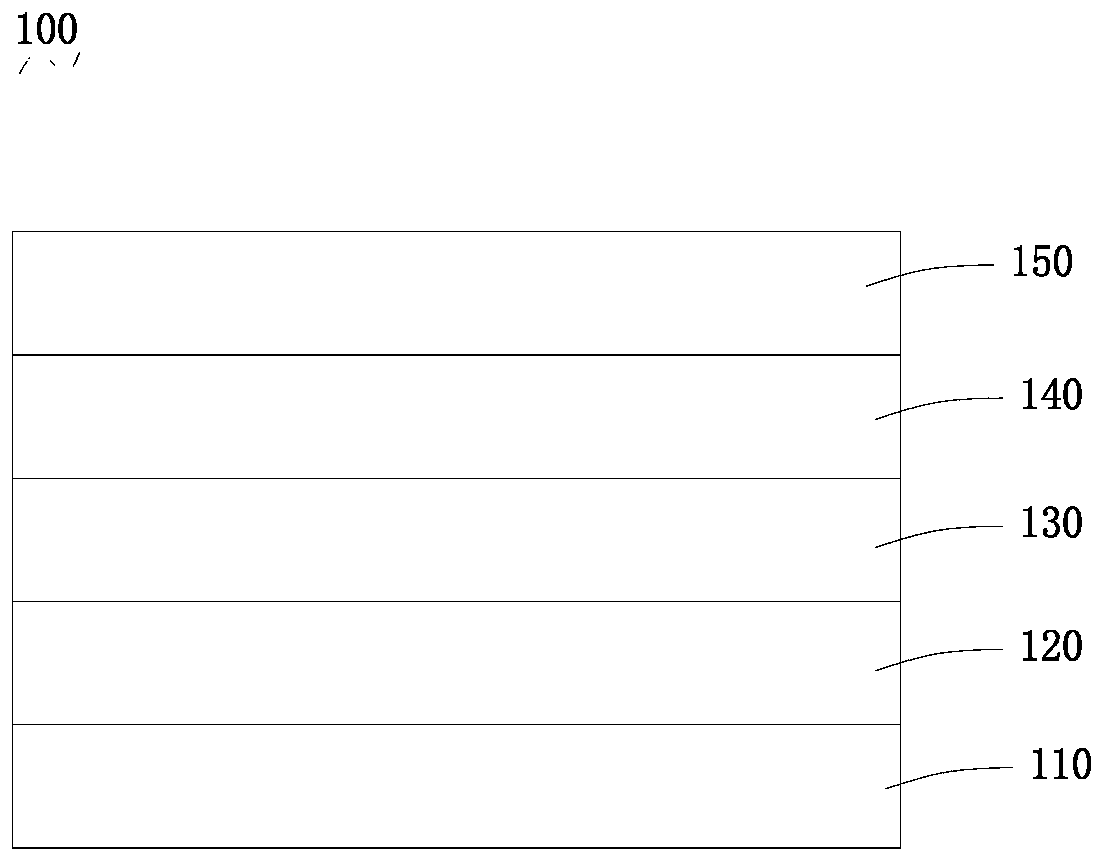

Perovskite layer, preparation method thereof and perovskite solar cell

PendingCN109888113AGood qualityHigh short-circuit current density and fill factorPhotovoltaic energy generationSemiconductor devicesBoiling pointComputational chemistry

Owner:昆山协鑫光电材料有限公司

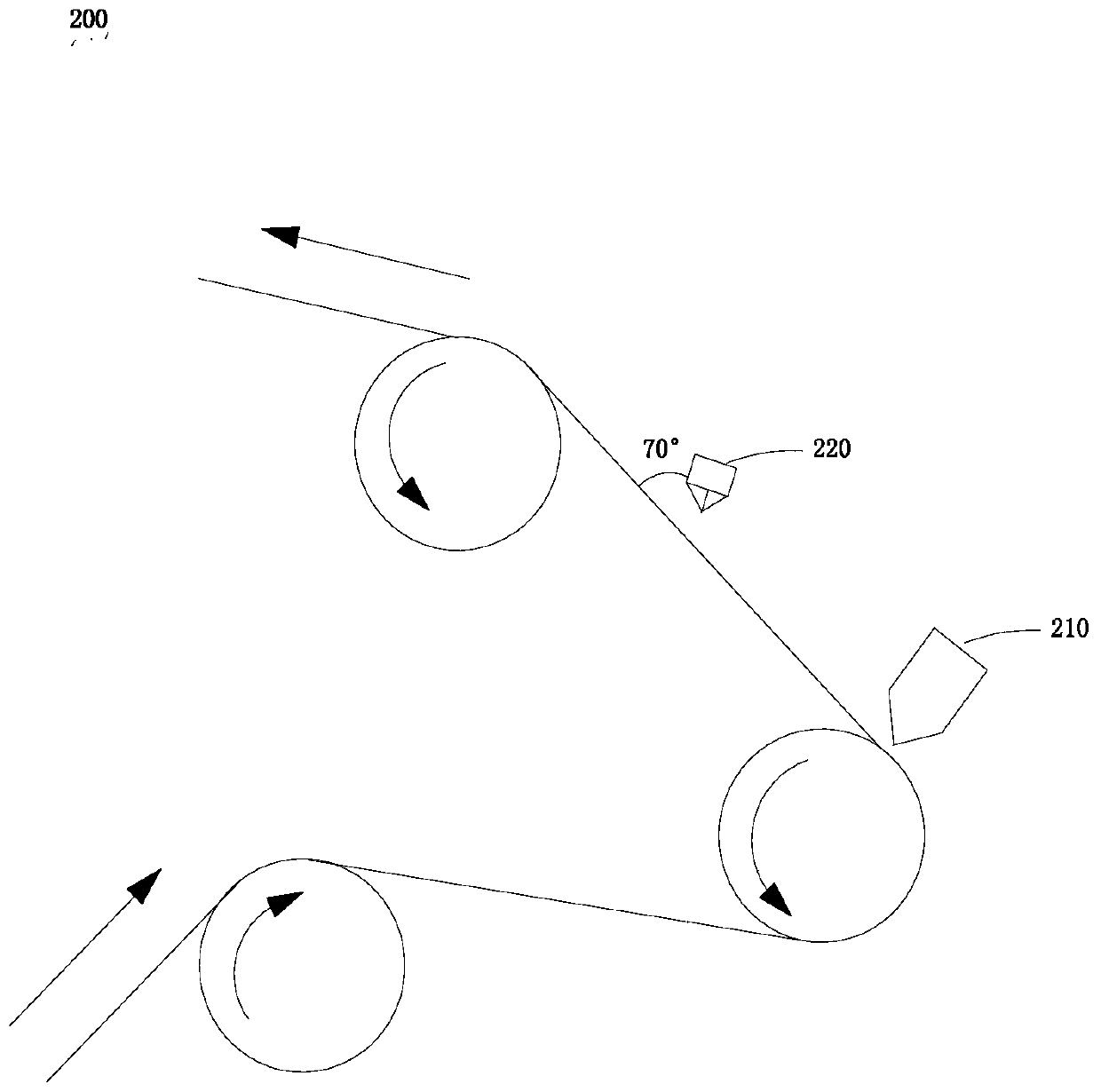

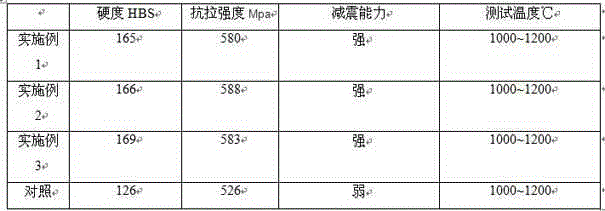

Titanium alloy for damping bicycle frame and preparation method thereof

Owner:TAICANG JUNHAO BICYCLE TECH CO LTD

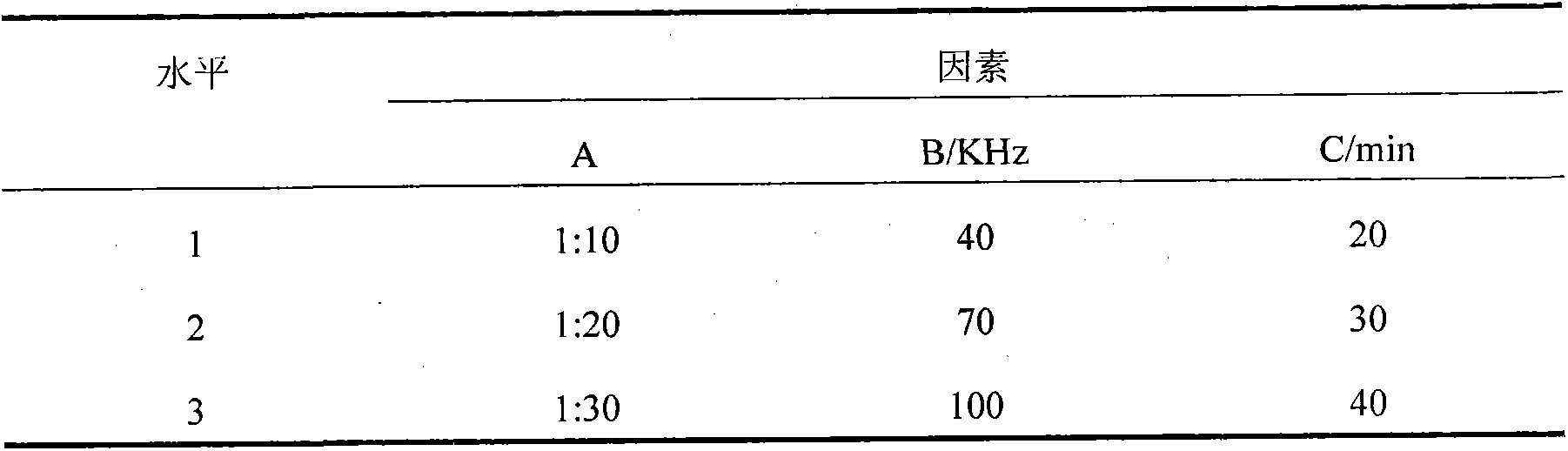

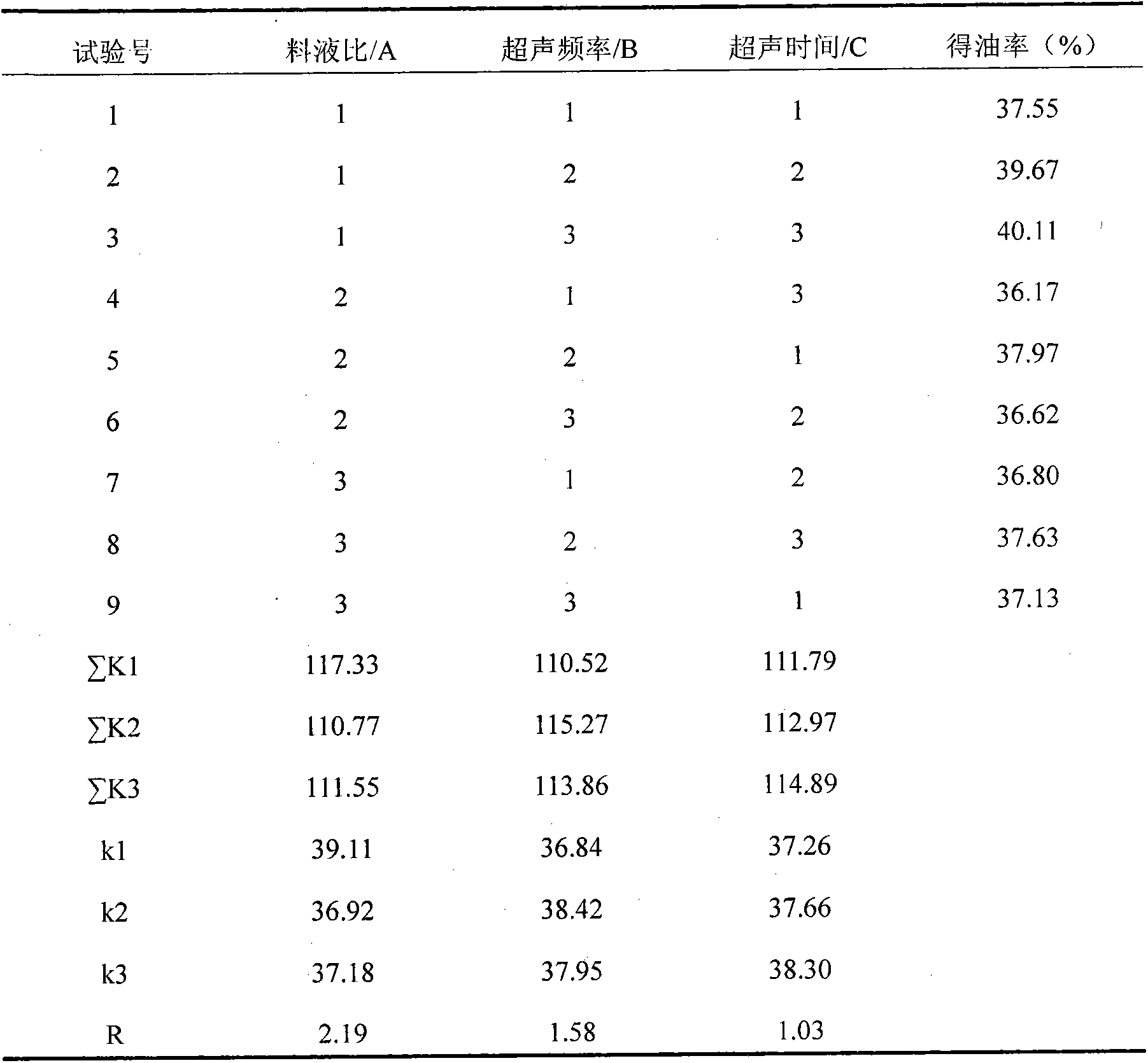

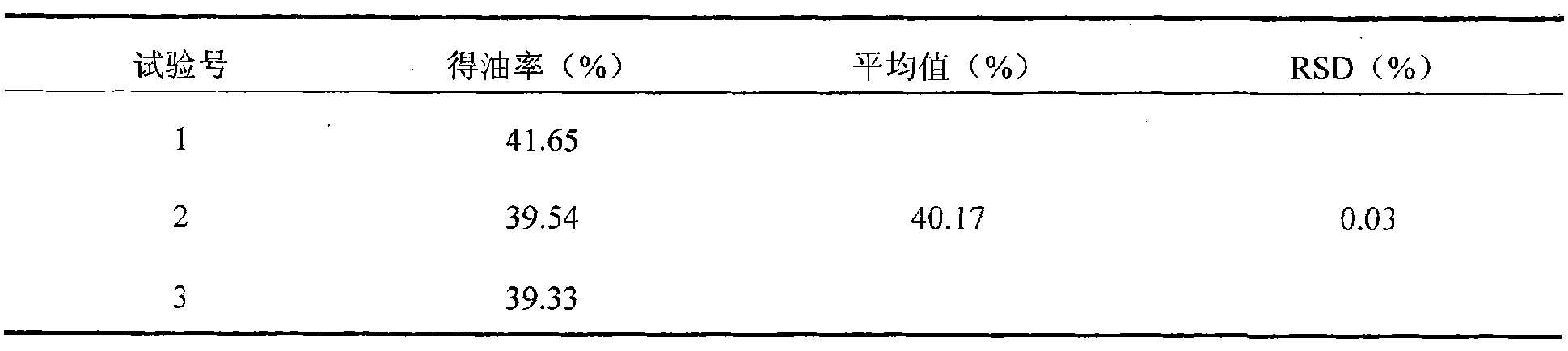

Method for extracting gynostemma pentaphylla seed oil through ultrasonic wave

Owner:SHAANXI NORMAL UNIV

Method and system for providing fast design for testability prototyping in integrated circuit designs

InactiveUS20050228616A1Good qualityImprove design flowCAD circuit designComplex mathematical operationsAND gateCell based

Owner:INCENTIA DESIGN SYST

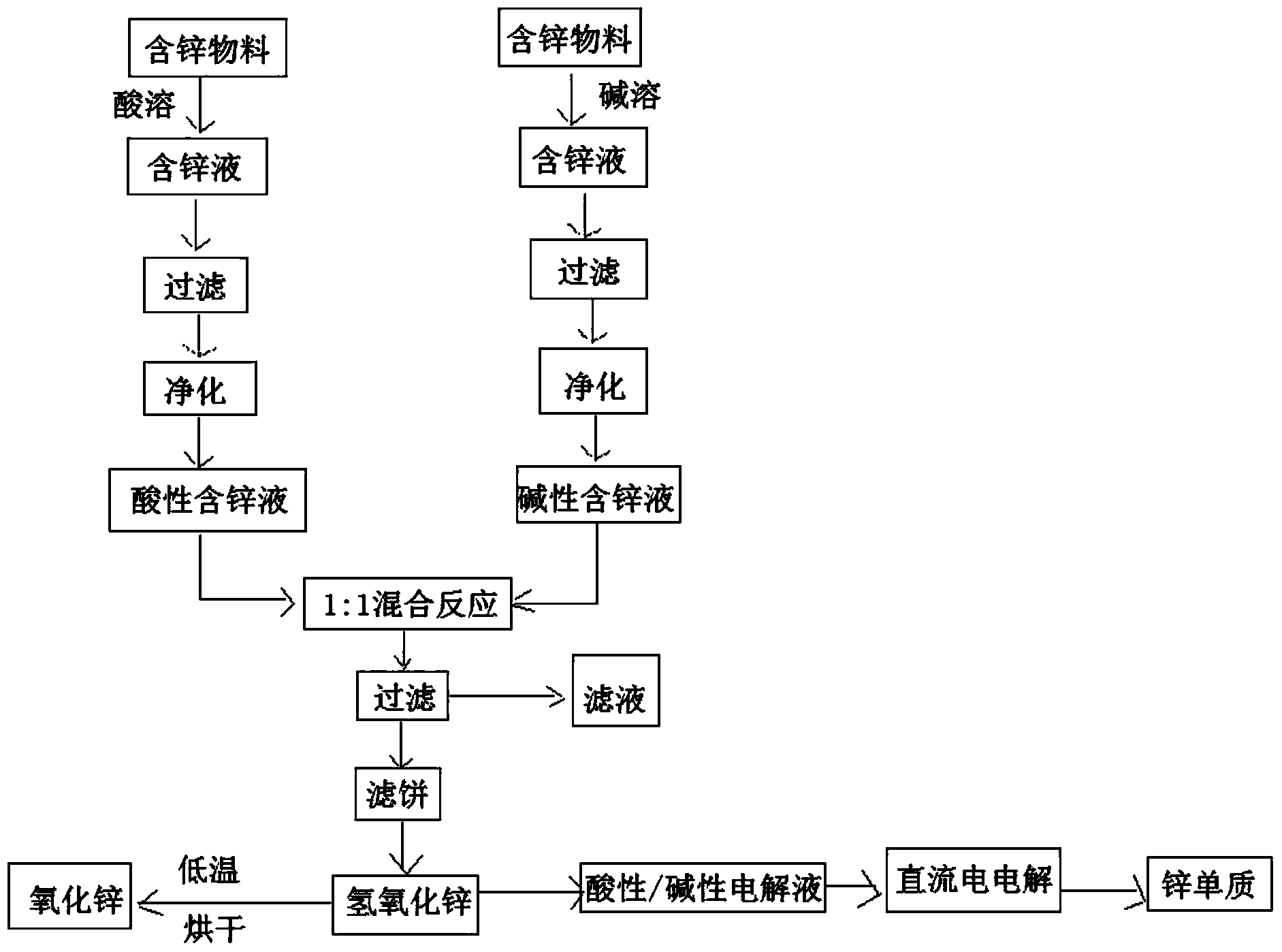

Process for producing zinc compound by acid and alkali combination method

ActiveCN104099479AGood qualityIncrease production profitProcess efficiency improvementChemistryCombination method

Owner:邱政

Application of seed coats/embryonic bodies and rhizomes obtained after harvest of sprout seedling vegetable to cultivation of pholiota adiposa

Owner:桂林健成生物科技开发有限公司 +1

Multi-view video reconstruction method based on GAN latent codes

Owner:FUZHOU UNIVERSITY

Aluminum drying device

InactiveCN103657987ADry evenlyGood qualityCoatingsPretreated surfacesAgricultural engineeringMachining

Owner:湖州镭宝机械有限公司

Planting method for reducing content of nitrate in spinach

InactiveCN106856909AGood qualityIncrease productionBiocideSeed and root treatmentFertilizerGermination

Owner:姚春光

Surface plasmon enhanced light-emitting diode

InactiveUS20110233514A1Good qualityImprove efficiencySemiconductor devicesSolid-state devicesLight-emitting diodeMetal

Owner:NAT CHENG KUNG UNIV

Backward compatible multi-carrier transmission system

InactiveUS20060193244A1Good qualityColor motion picture films scanningColor television with bandwidth reductionMulti carrierOver modulation

Owner:NXP BV

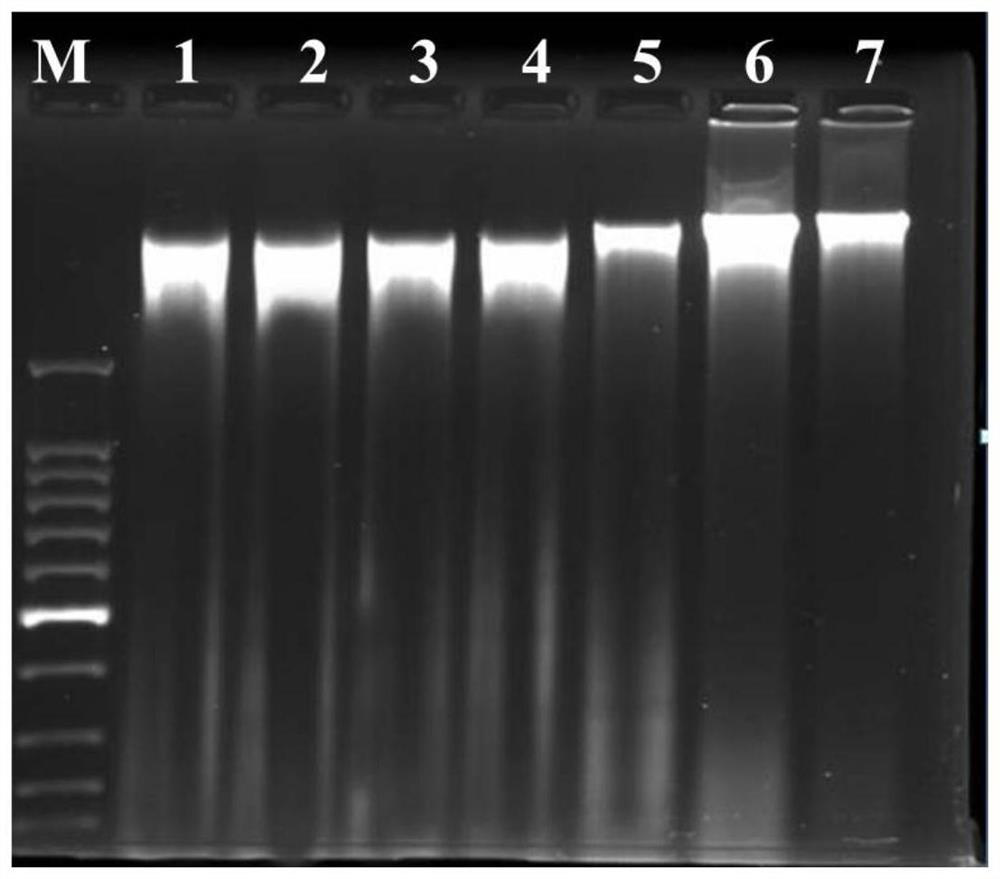

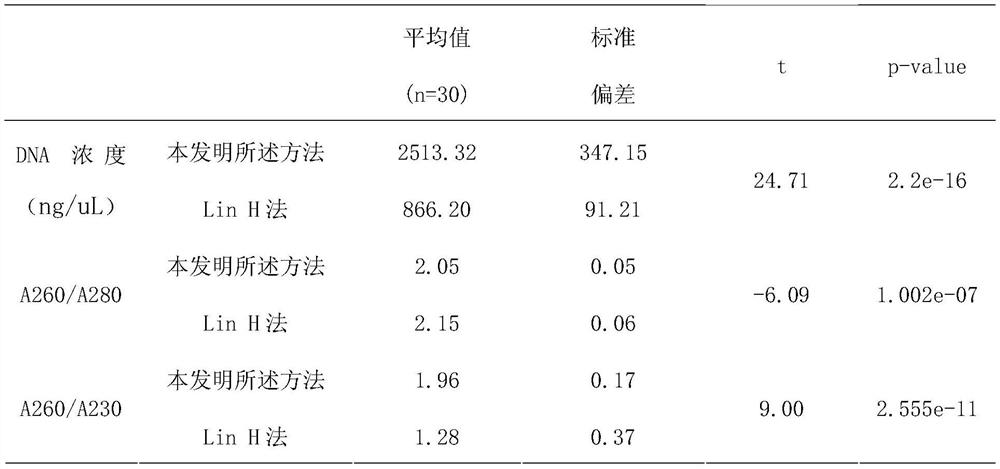

Citrus DNA rapid extraction method

Owner:广西特色作物研究院

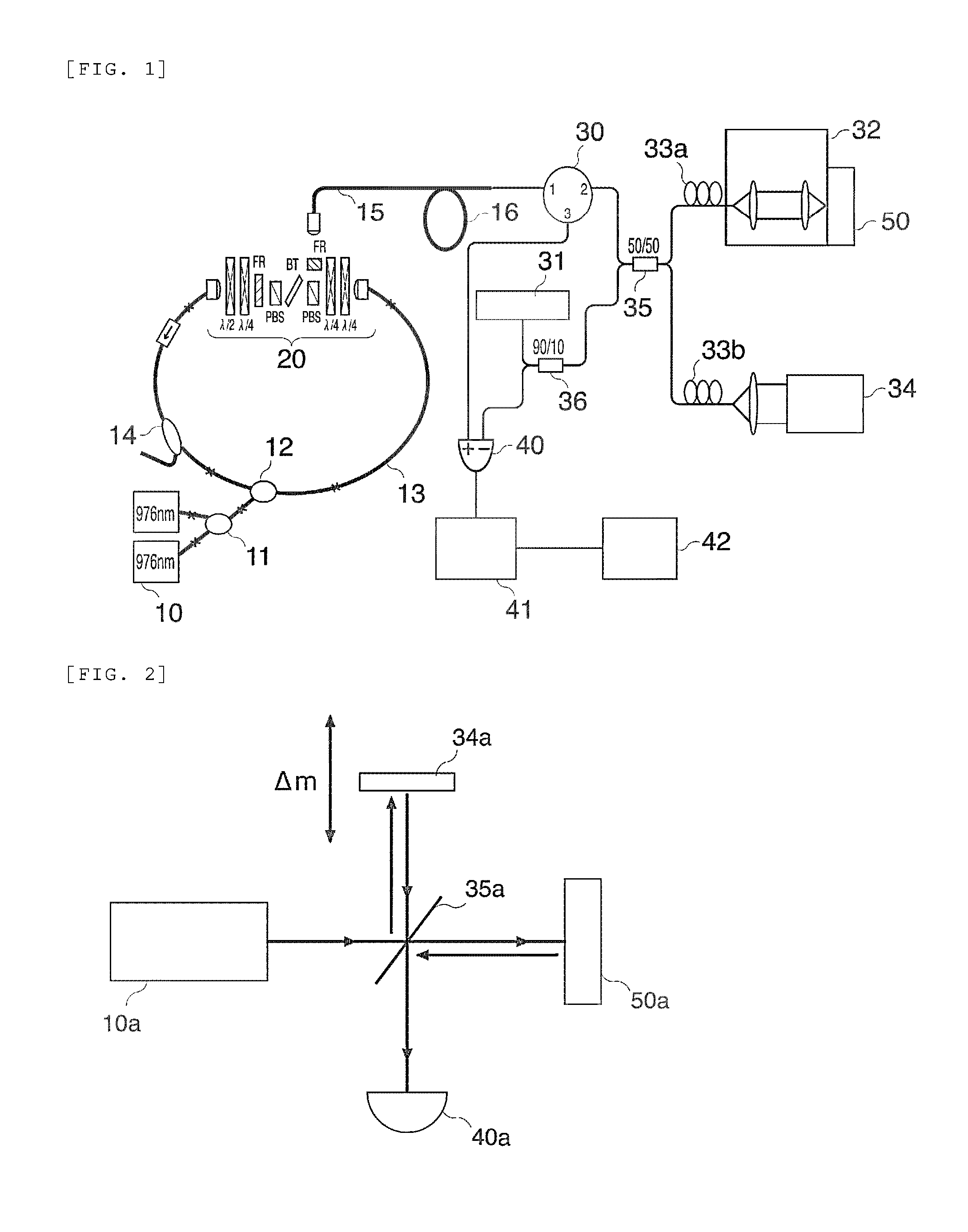

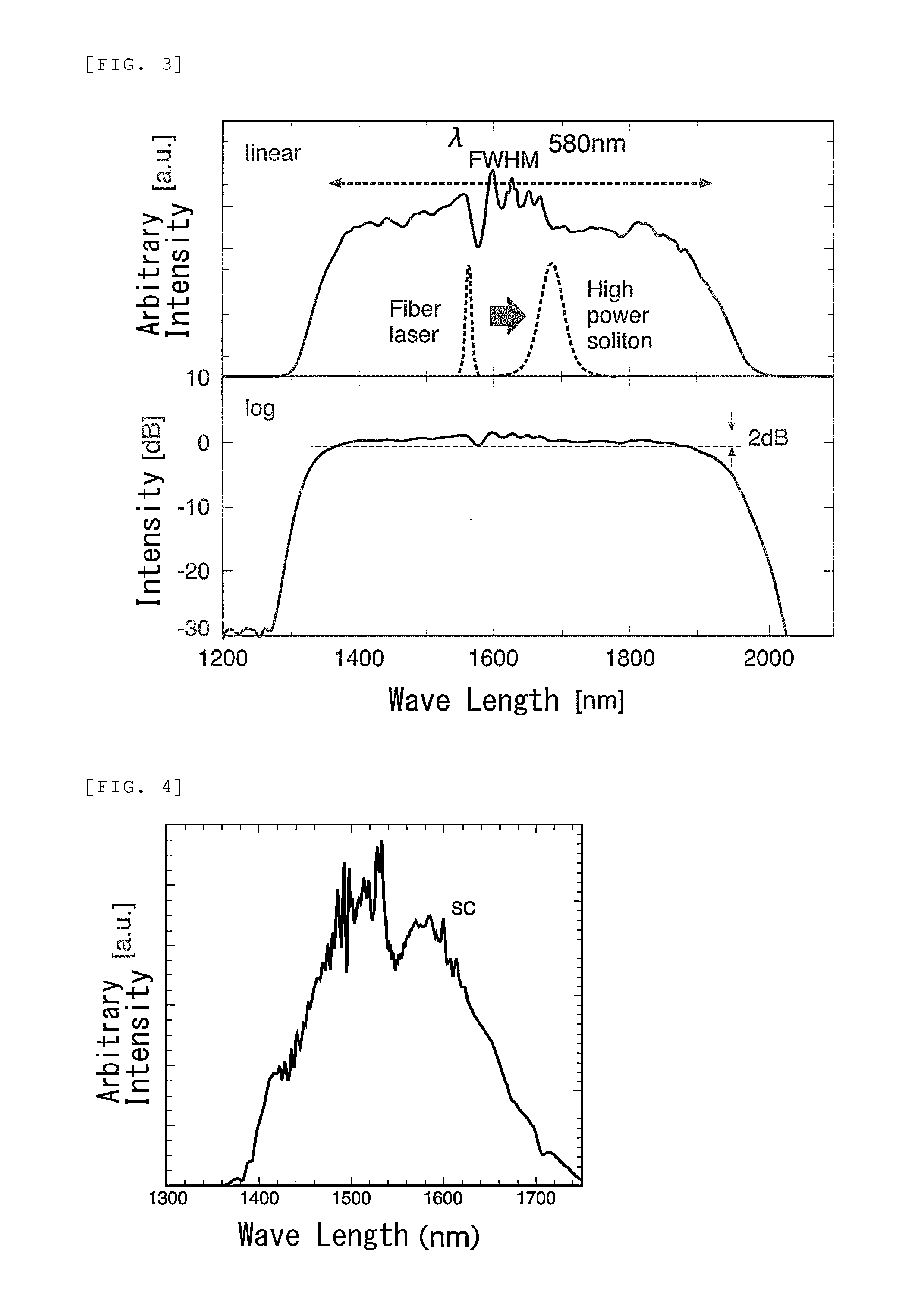

Method for observing protein crystal

InactiveUS20130184445A1Improve accuracyQuality improvementMaterial analysis by optical meansDepsipeptidesBroadbandSupercontinuum

Owner:OSAKA UNIV

Method for recovering and purifying ethanol-ethyl acetate-piperazine waste solvent

InactiveCN113527057AGood qualityHigh yieldCarboxylic acid esters preparationHydroxy compound preparationAzeotropic distillationDehydration

Owner:四川熔增环保科技有限公司

Plastic coil machine and method for producing plastic coil dry wall screws

PendingCN108408127AGood qualityIncrease productivityWrapping material feeding apparatusConveyor beltDrive motor

Owner:南京诺淳五金制品有限公司

Method for manufacturing low-offset flat band voltage SiC MOS capacitor

InactiveCN101540280AAccelerateGood qualitySemiconductor/solid-state device manufacturingCapacitanceChemical vapor deposition

Owner:XIDIAN UNIV

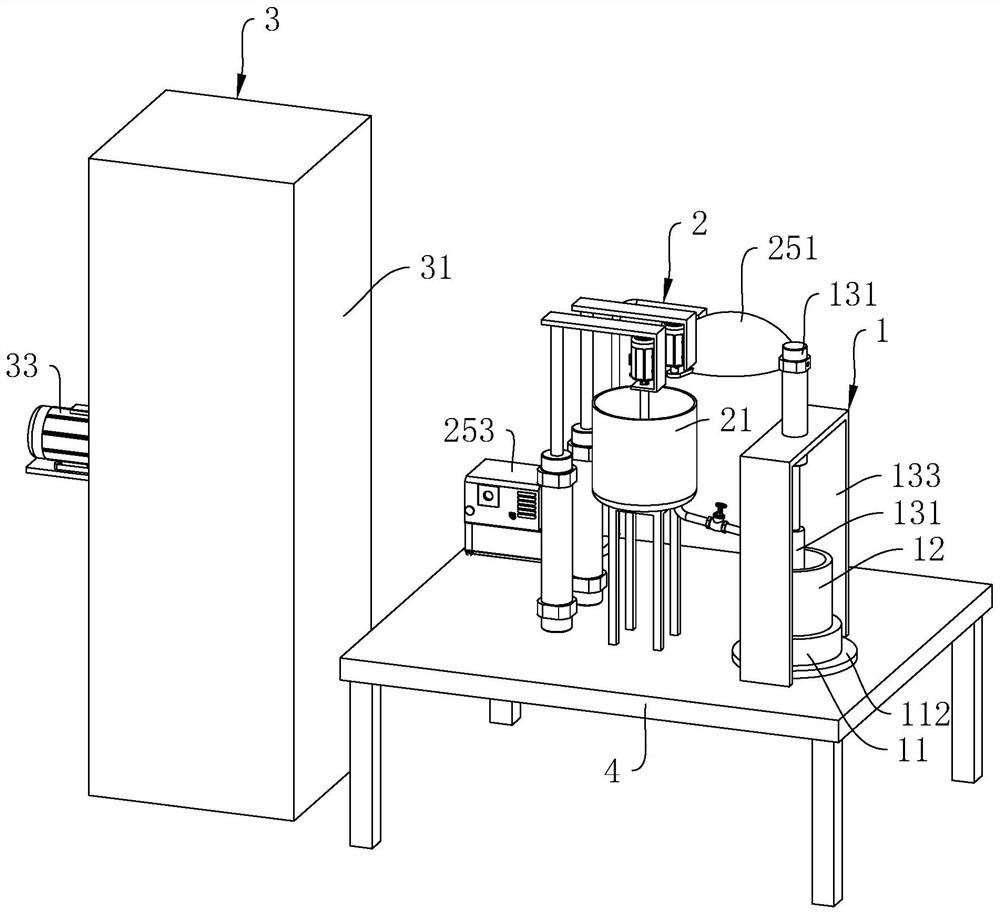

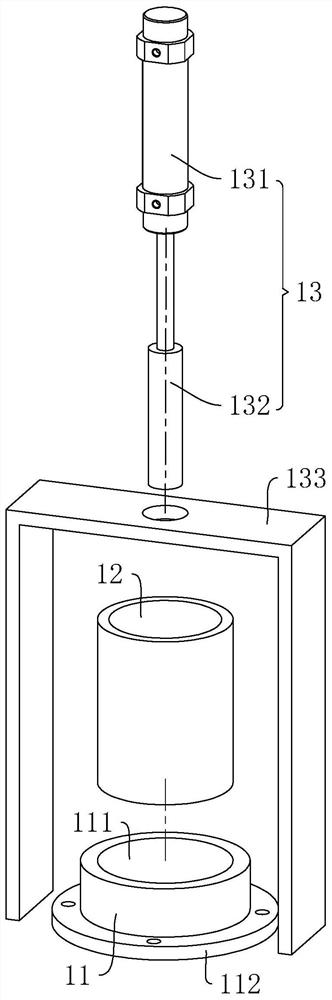

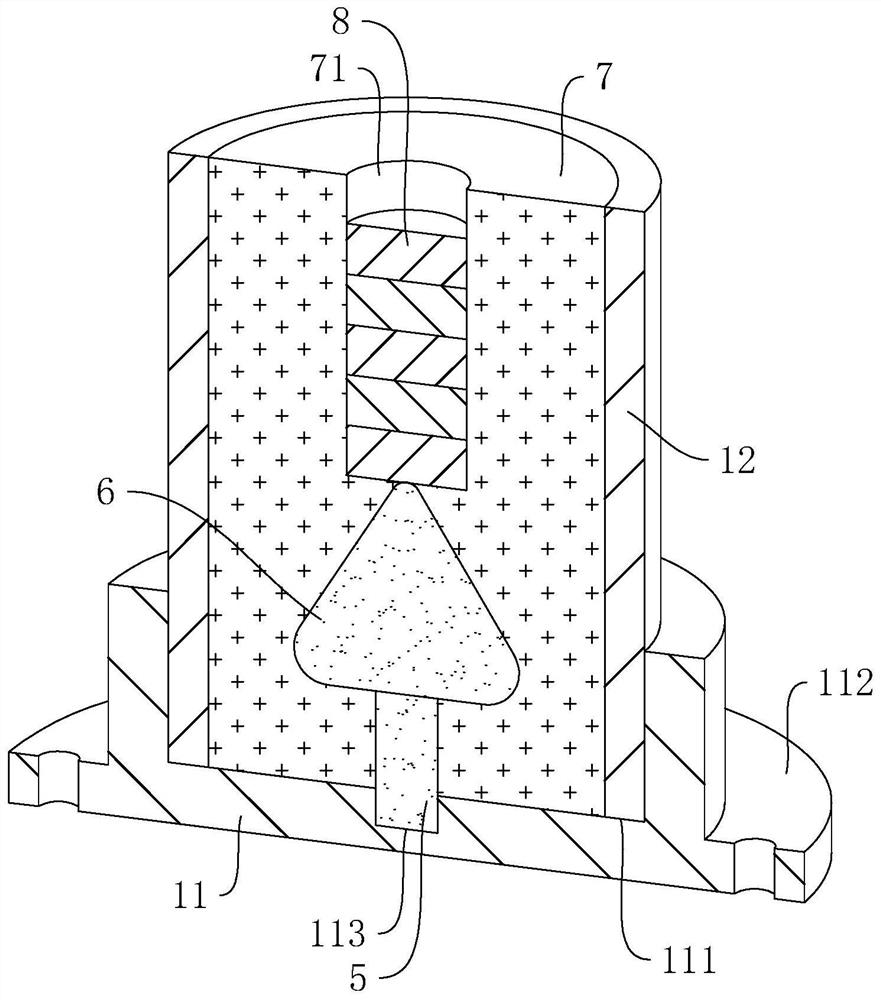

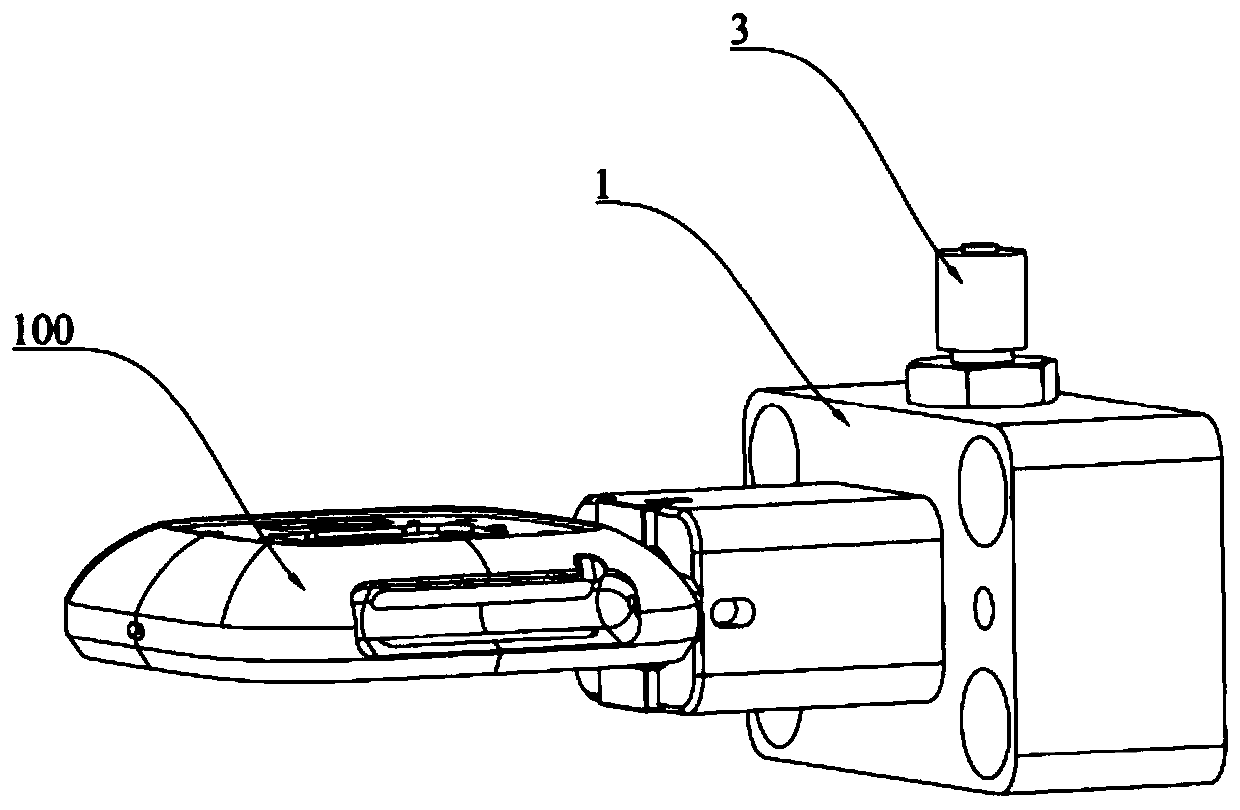

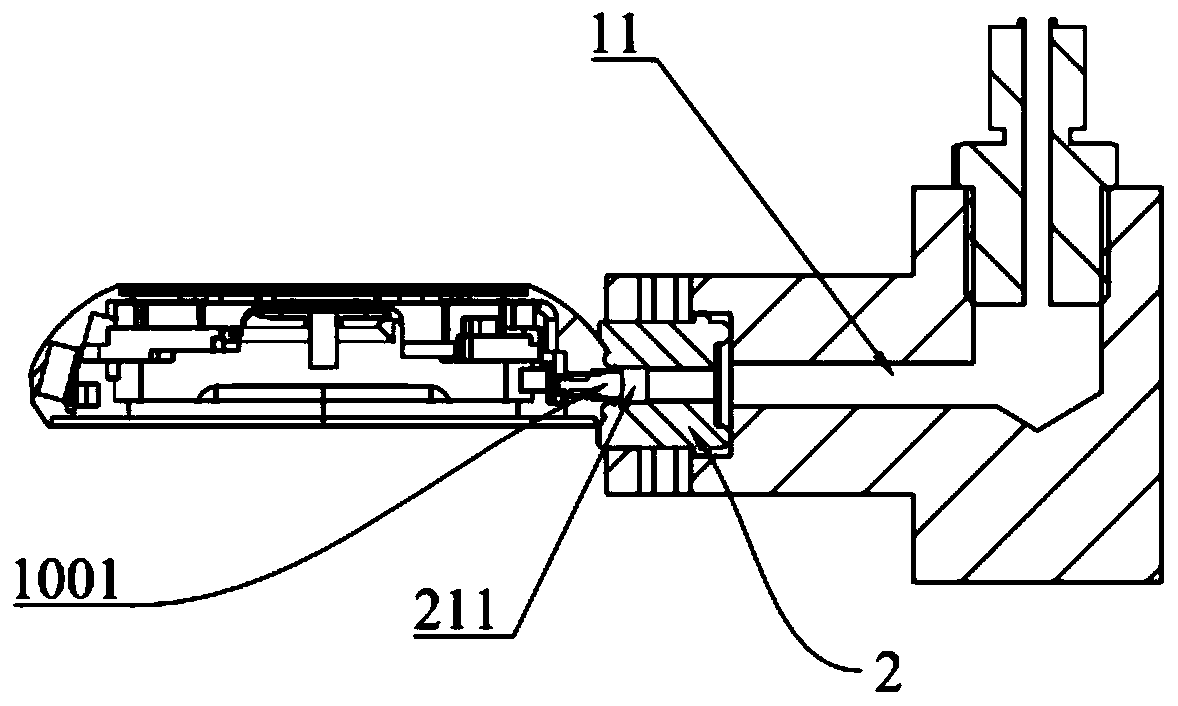

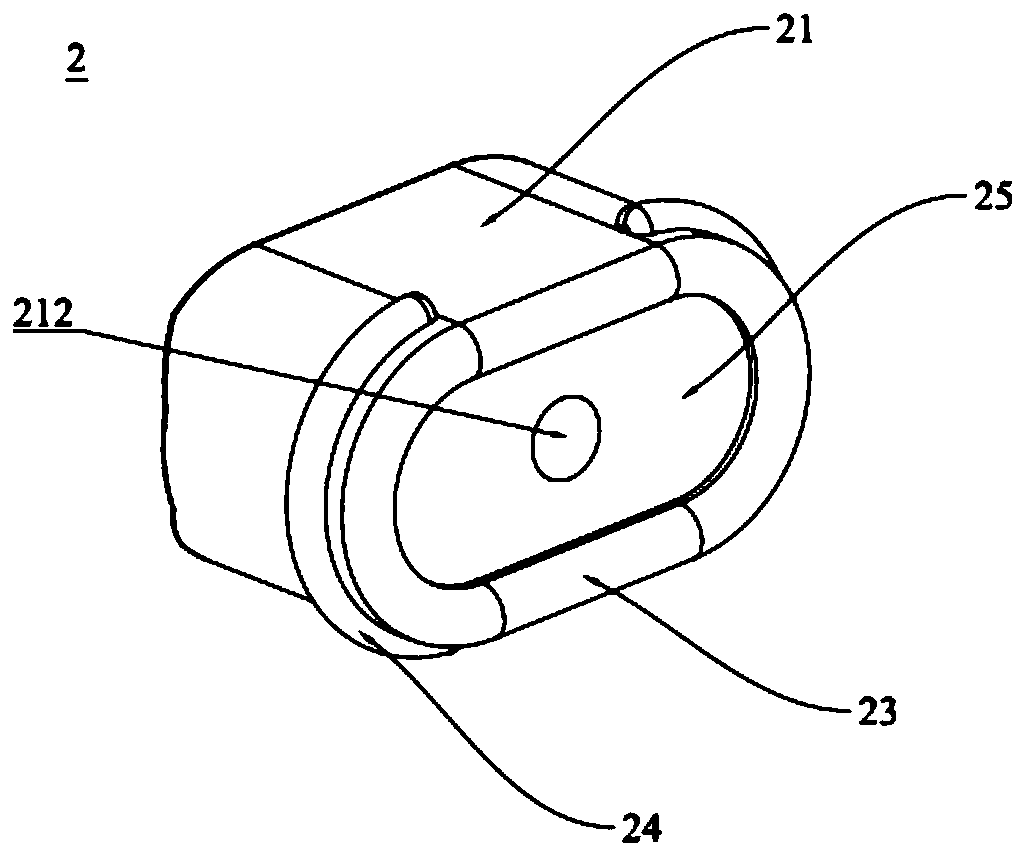

Sealing device

PendingCN111156315AGood qualityGood applicabilityEngine sealsMeasurement of fluid loss/gain ratePhysicsEngineering

Owner:BOZHON PRECISION IND TECH CO LTD

Coarse grain salty egg-yolk puff and preparation method thereof

Owner:南京明仁光电科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap