Vacuum cleaner shell soft positioning type injection molding technology

A vacuum cleaner and positioning technology, applied in the coating and other directions, can solve the problems of high surface roughness, low strength and low efficiency of the injection molding process of the finished product, and achieve the effect of reducing the unevenness of the outer surface, improving the quality and improving the injection molding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0033] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

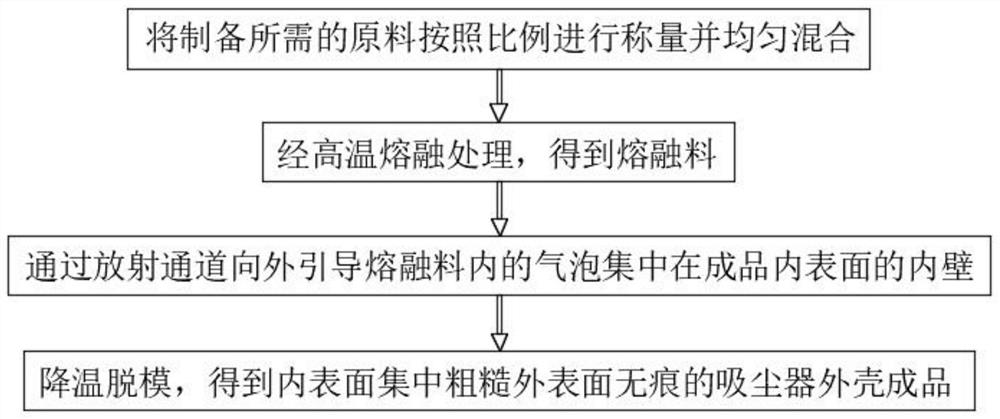

[0034] As attached figure 1 The soft positioning type injection molding process for a vacuum cleaner housing according to the present invention is shown, and the soft positioning type injection molding process for a vacuum cleaner housing includes the following steps:

[0035] S1. First, weigh the raw materials required for the preparation of the vacuum cleaner shell in proportion and mix them evenly;

[0036] S2. The mixed raw materials are added to the reactor for high-temperature melting treatment, and stirring is continuously performed during the melting process to obtain a molten material;

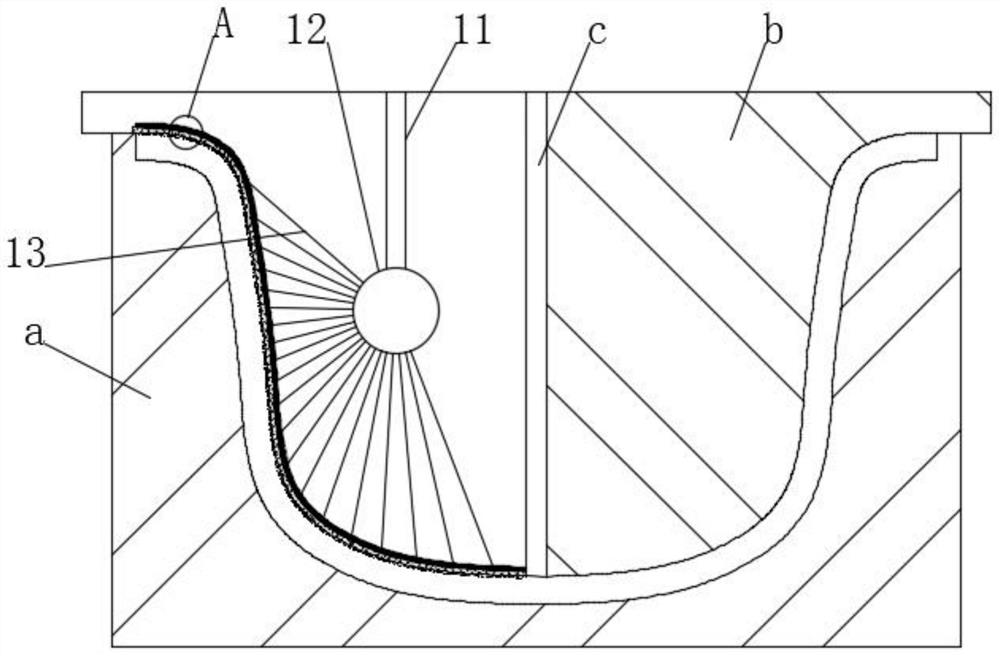

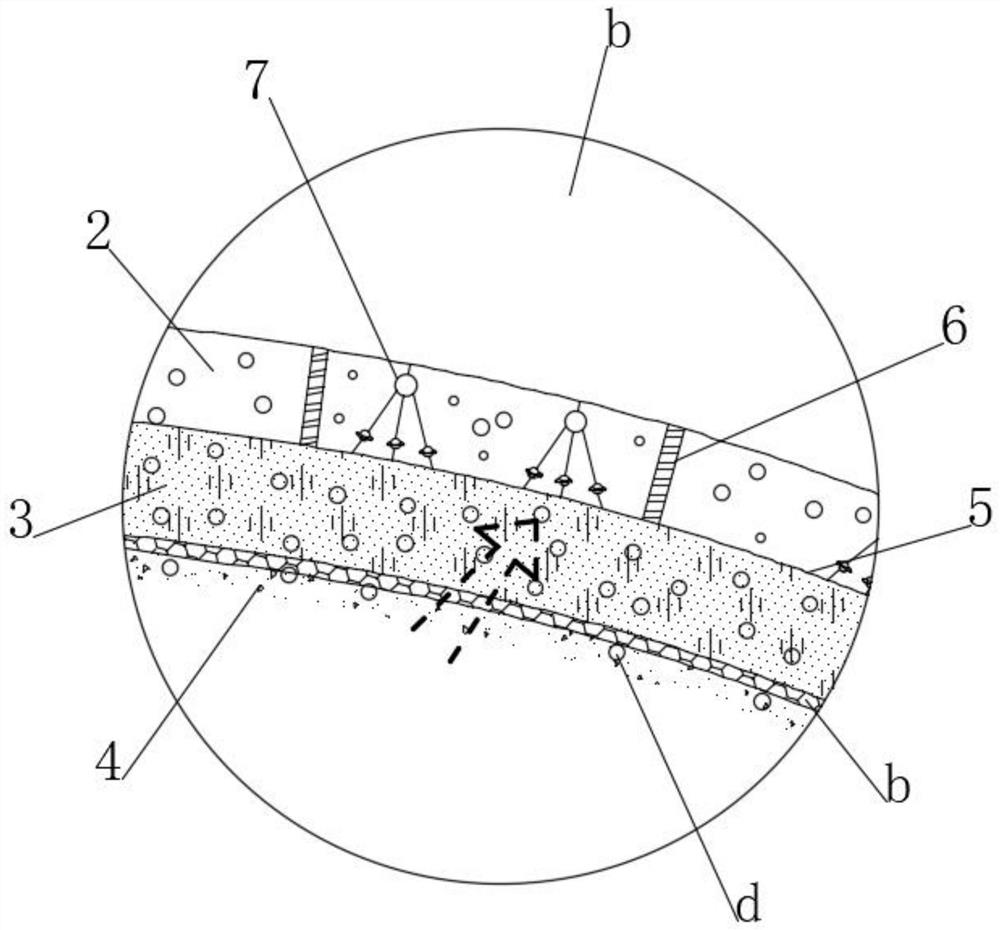

[0037] S3. Under the action of the plastic injection machine, the molten material is passed into the soft positioning and non-marking mold through the injection port, and then sucked outward through the radiation channel, thereby guiding the bubbles in the molten mat

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap