Hand-held rake-like machine for wolfberry plucking

A picking machine and wolfberry technology, which is applied in the direction of picking machines, harvesters, agricultural machinery and tools, etc., can solve the problems of restricting industrial development, high branch damage rate, and low harvesting efficiency, so as to reduce labor intensity and fruit damage The effect of low yield and high picking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

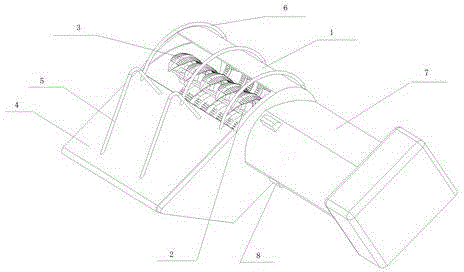

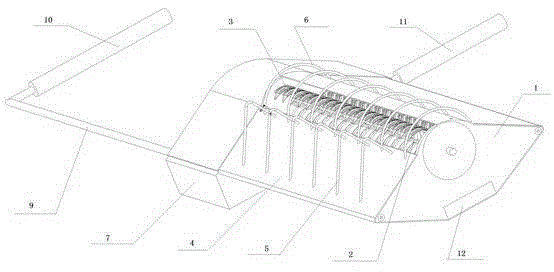

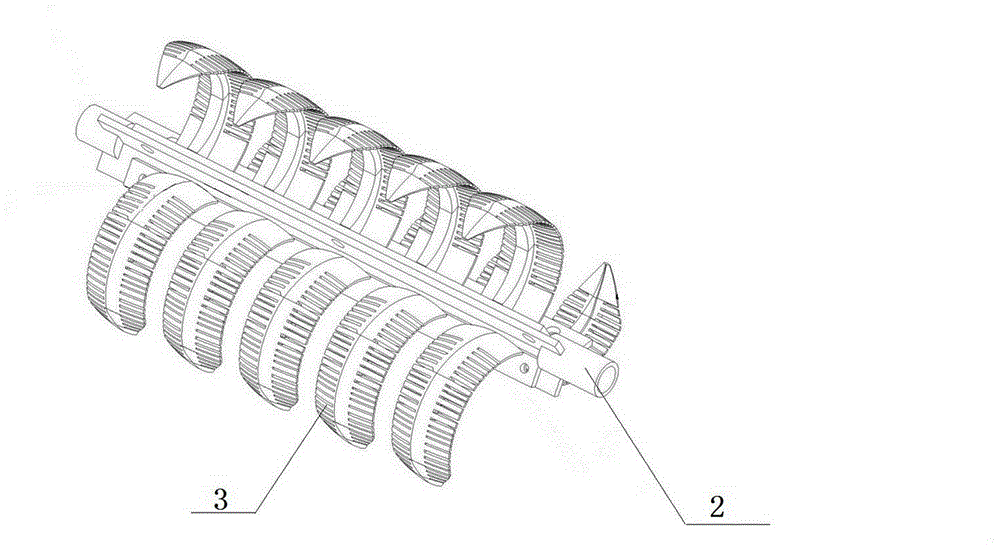

[0010] A hand-held comb-rake type wolfberry picking machine, such as figure 1 , figure 2 , image 3 As shown, the upper opening of the fruit harvesting bin body 1 is open, in the fruit harvesting bin body 1, a fruit rake shaft 2 is installed through a bearing, and a rake brush fruit tooth row is arranged radially evenly on the fruit rake shaft 2 The rake brush fruit tooth row is a rake brush fruit tooth comb 3 arranged evenly along the axial direction of the rake brush fruit shaft 2, and the front side of the opening of the fruit harvesting bin body 1 is connected with a guide plate 4, and the guide plate 4 is evenly arranged. The cloth is provided with a front guide comb rail 5 that is perpendicular to the fruit raking device shaft 2, and a rear guide comb rail 6 is arranged laterally on the opening of the fruit harvesting bin body 1, and the fruit harvesting bin body 1 is connected to the casing 7, A battery-driven deceleration motor is installed in the casing 7 , and the de

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap