Heating cable with invisible joint and manufacturing method thereof

A technology for heating cables and manufacturing methods, applied in the direction of heating elements, heating element materials, heating element shapes, etc., can solve the problems of high contact resistance of explicit joints, poor high temperature resistance, overheating in working conditions, etc., so that it is not easy to break , Improve flexibility, improve the effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

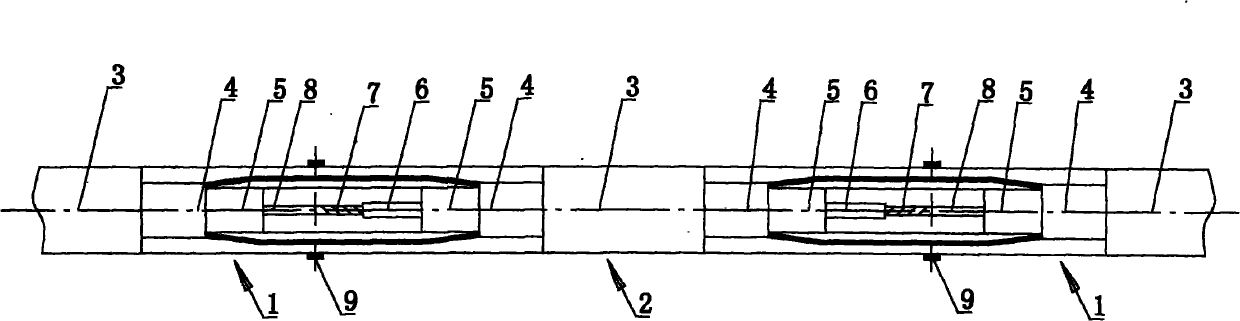

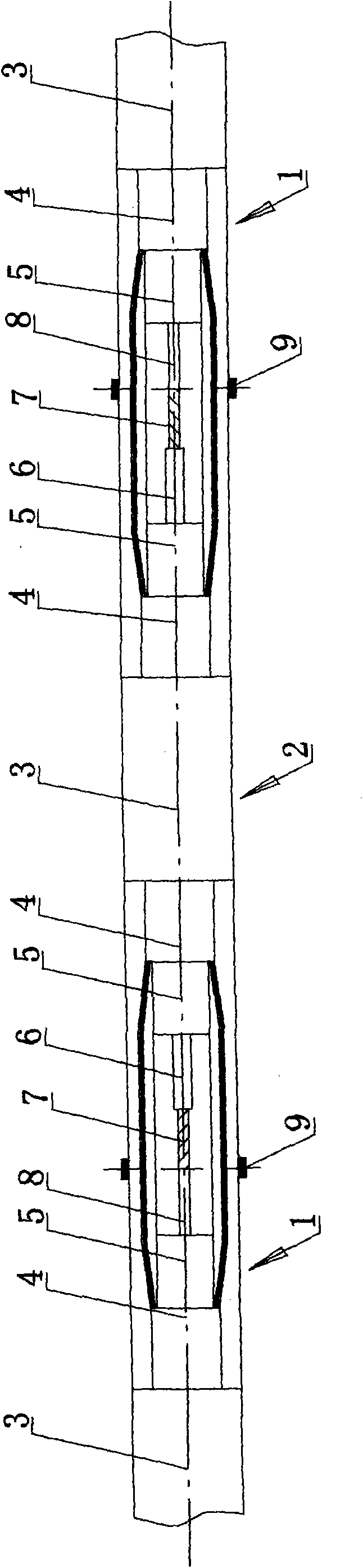

[0024] Such as figure 1 and figure 2 As shown, the heating cable with invisible joints in this embodiment includes a heating section 2 and a wire section 1 respectively connected to both ends of the heating section 2. The heating section 2 includes a sheath layer 3, a shielding layer 4, Insulation layer 5, several high-temperature-resistant insulation layers 6 and several heating cores 7 wrapped in high-temperature-resistant insulation layer 6, said wire segment 1 sequentially includes sheath layer 3, shielding layer 4, insulation layer 5 and The cold wire 8 corresponding to the number of the heating core 7 used for conduction, the cold wire 8 is connected to the heating core 7, and the joint mark 9 is provided on the sheath layer 3 where the cold wire 8 is connected to the heating core 7; The junction of the cold wire 8 and the heating core 7 is brazed connection; the number of the high-temperature-resistant insulating layer 6 and the heating core 7 is one; the high-tempera...

Embodiment 2

[0037] In the heating cable with invisible joints in this embodiment, there are two high-temperature-resistant insulating layers 6 and two heating cores 7 , and other mechanisms, usages and manufacturing methods are basically the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap