Suction nozzle structure

A technology of body and support, which is applied in the field of display screen detection equipment, can solve problems such as glass breakage, thin glass deformation and depression, etc., and achieve the effects of avoiding breakage, facilitating installation and adjustment, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

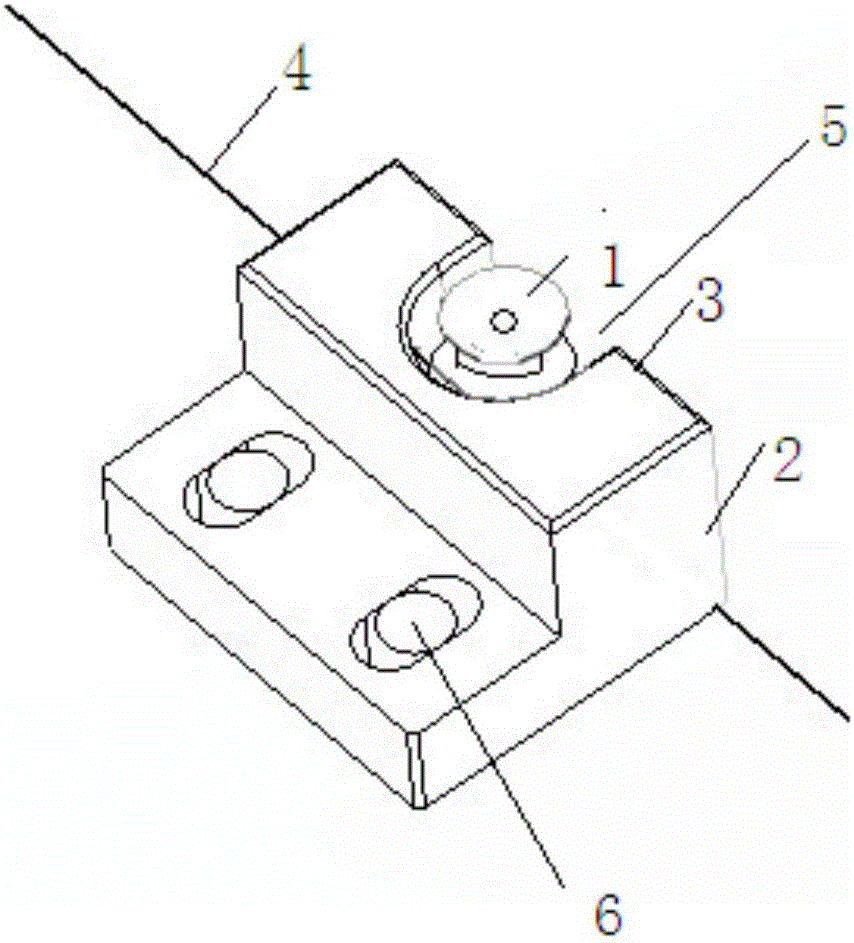

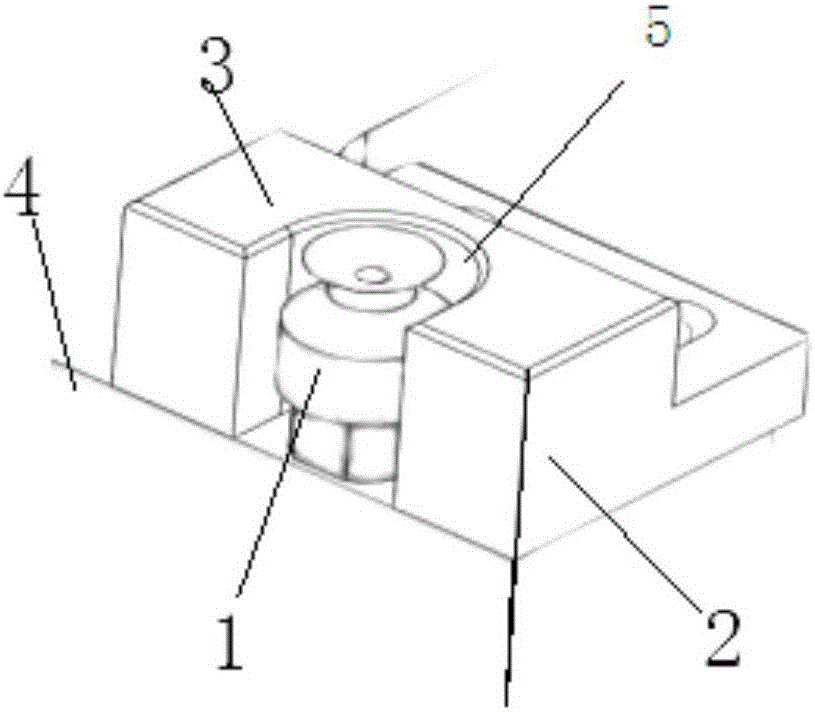

[0023] Such as figure 1 Shown and figure 2 As shown, figure 1 Is a schematic diagram of the nozzle structure of the present invention; figure 2 It is a schematic diagram of the nozzle structure of the present invention from another perspective. This embodiment provides a nozzle structure. The nozzle structure includes a base 4, a nozzle body 1, arranged on the base 4, and a support 2. The support 2 has a support surface 3, and the support surface 3 is located on the suction nozzle. Around the nozzle body 1, the nozzle body 1 is used for sucking the substrate, and is used for supporting the substrate together with the supporting surface 3. In this way, when the suction nozzle body 1 sucks and supports the substrate, the area around t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap