Main spindle part of spool wire-receiving machine

A technology of spindle parts and wire take-up machines, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of affecting work efficiency and poor bearing capacity of pins, and achieves reasonable structure, easy installation, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

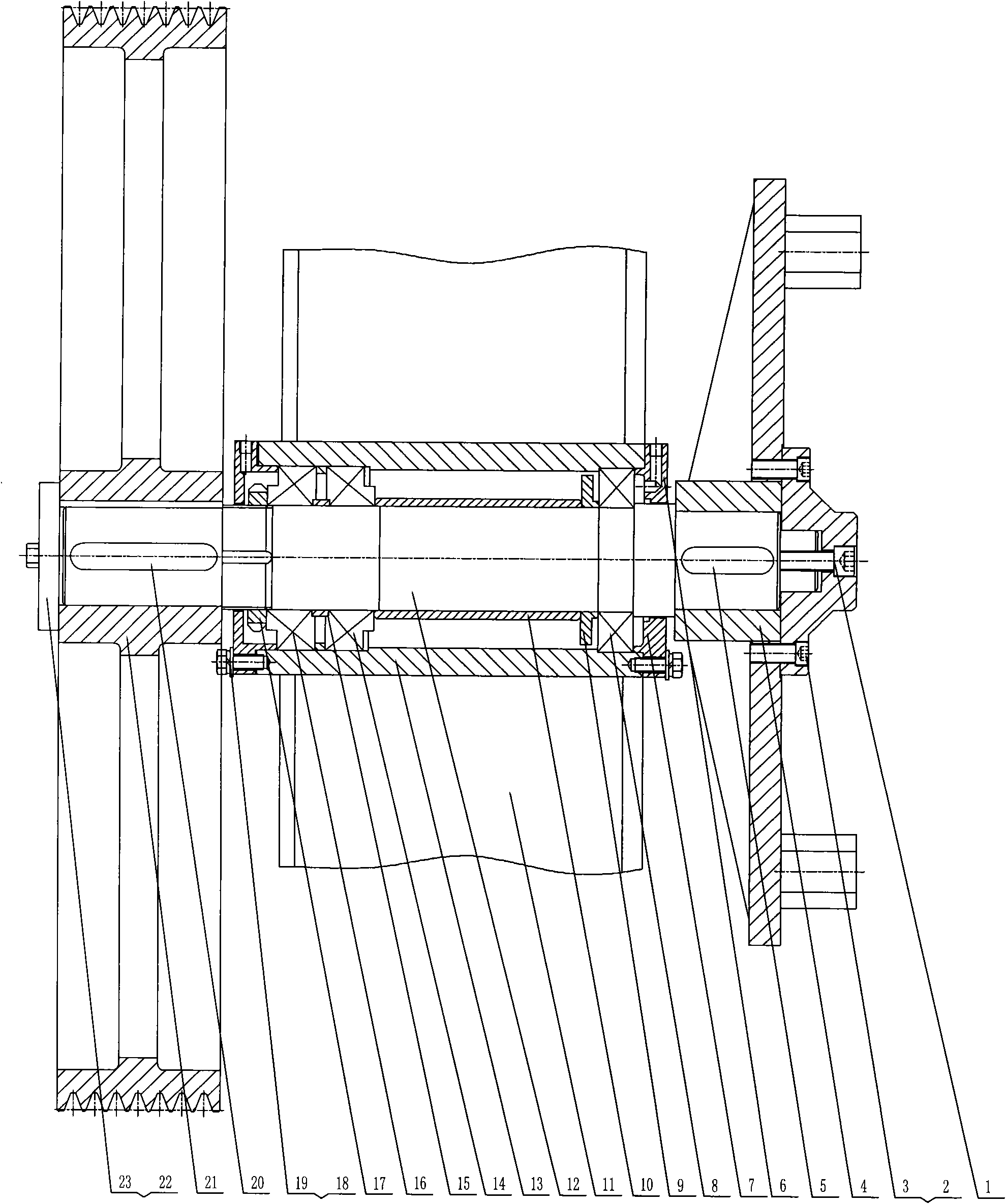

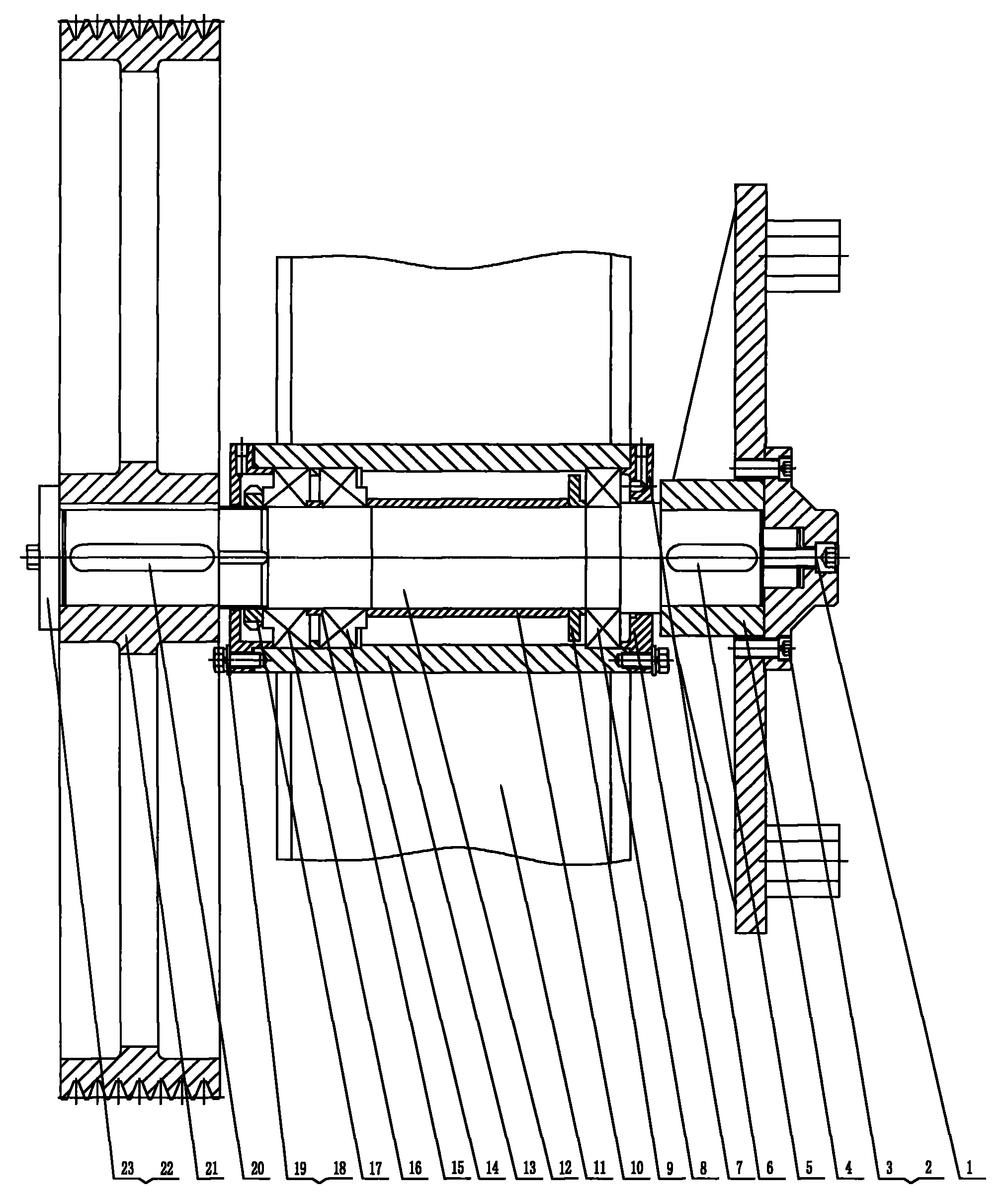

[0008] As shown in the figure, the present invention mainly includes a second hexagon socket head screw 1, a right top 2, a first hexagon socket head screw 3, a dial 4, a key 5, an oil cup 6, a transparent cover 7, a first bearing 8, and an oil retaining sleeve 9. Cover 10, frame 11, main shaft 12, bearing seat 13, second bearing 14, pad cover 15, third bearing 16, round nut 17, transparent cover 18, bolt 19, key 20, large pulley 21, boring Cover 22, bolt 23.

[0009] The present invention first connects the dial 4 to the main shaft 12 with the key 5, the outer center of the dial 4 is covered with the right top 2, the outer side of the dial 4 is provided with a protrusion, and the dial 4 and the right top 2 pass through the first inner hexagon The screw 3 is connected, and the right top 2 is connected with the main shaft 12 through the second hexagon soc

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap