Unreeling device special for embedded silk thread

A wire and longitudinal arrangement technology is applied in the field of special unwinding devices embedded in guide wires, which can solve the problems of normal work affecting guide wire unwinding, affecting the quality of work, and high labor intensity, so as to solve the problem of guide wire unwinding, reducing The effect of labor intensity and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

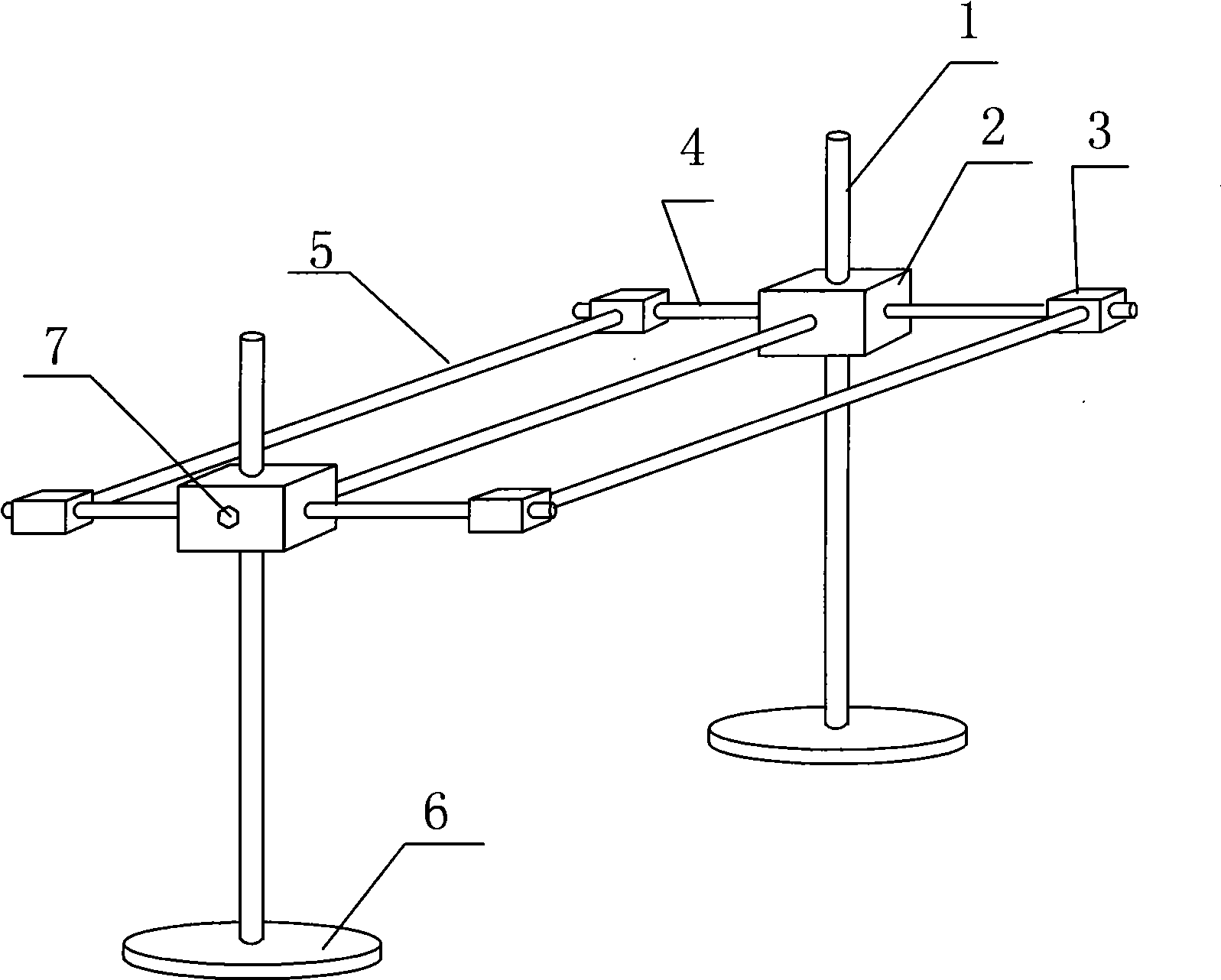

[0012] The special unwinding device for the guide wire of the present invention is manufactured as a general-purpose machining process, and the installation is also very simple and convenient. When installing, the vertical column 1 and the base are fixed, and then the three horizontal vertical rack bars 5 are respectively connected to the guide wire. Part 2 and the auxiliary guide wire connecting part are connected by threads, and the vertical through hole on the leading wire connecting part 2 connected with the horizontal vertical frame bar 5 is placed on the vertical column, positioned and fixed with the top wire, and finally the horizontal vertical The auxiliary guide wire connectors of the racking rod 5 are respectively inserted into the three-way holes from both ends of the horizontal racking rod 5, and the horizontal vertical racking rod 5 is rotated so that the positive and negative threads at both ends are screwed into the horizontal horizontal racking rod. on the pole.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap