Adhesive tape cutting machine

A technology for dividing tape and tape cutting, applied in metal processing and other directions, can solve the problems of high labor intensity, low production efficiency, long cutting time, etc., and achieve the effect of flexible and convenient maintenance, convenient operation, and accurate external dimensions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

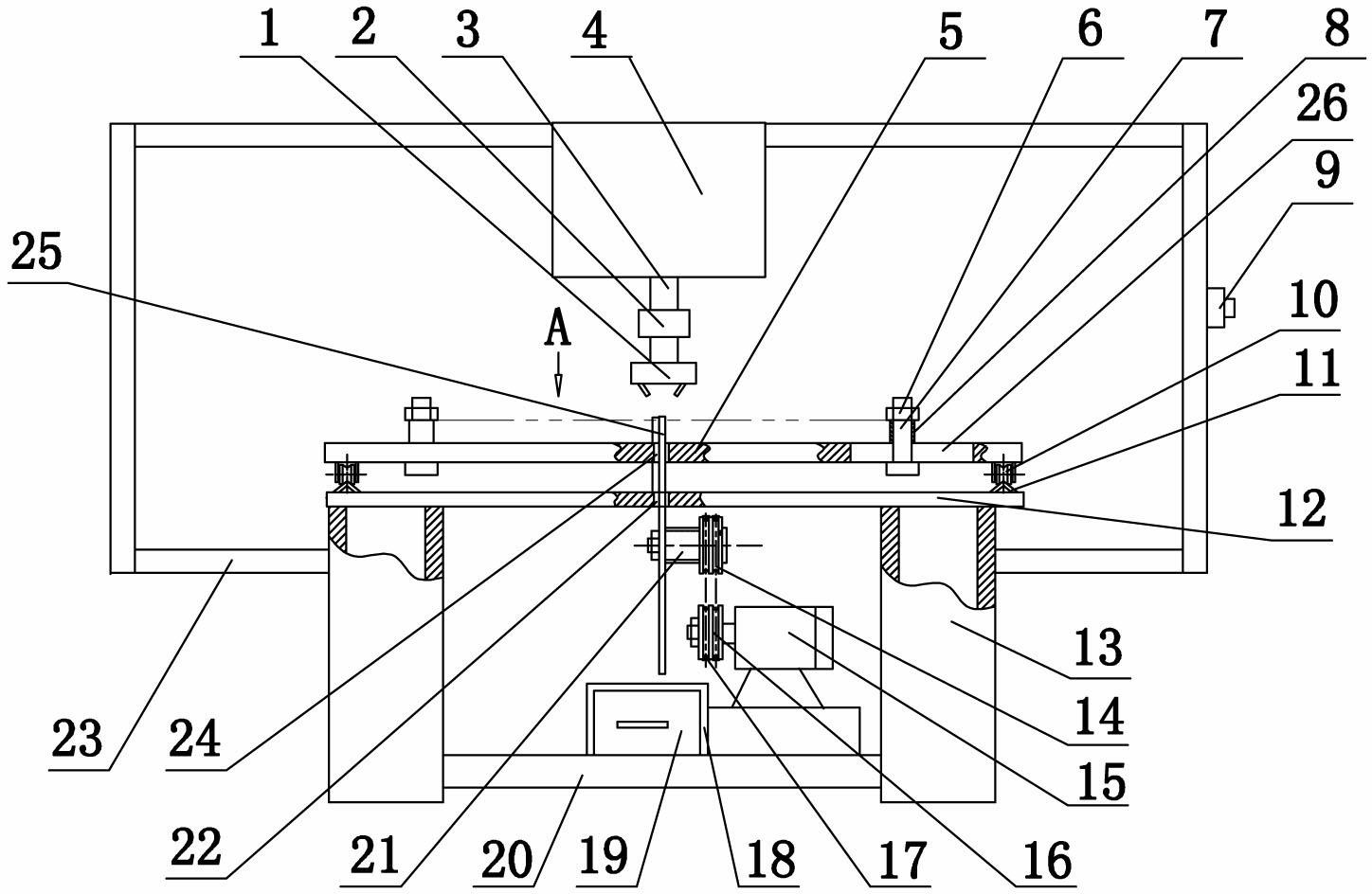

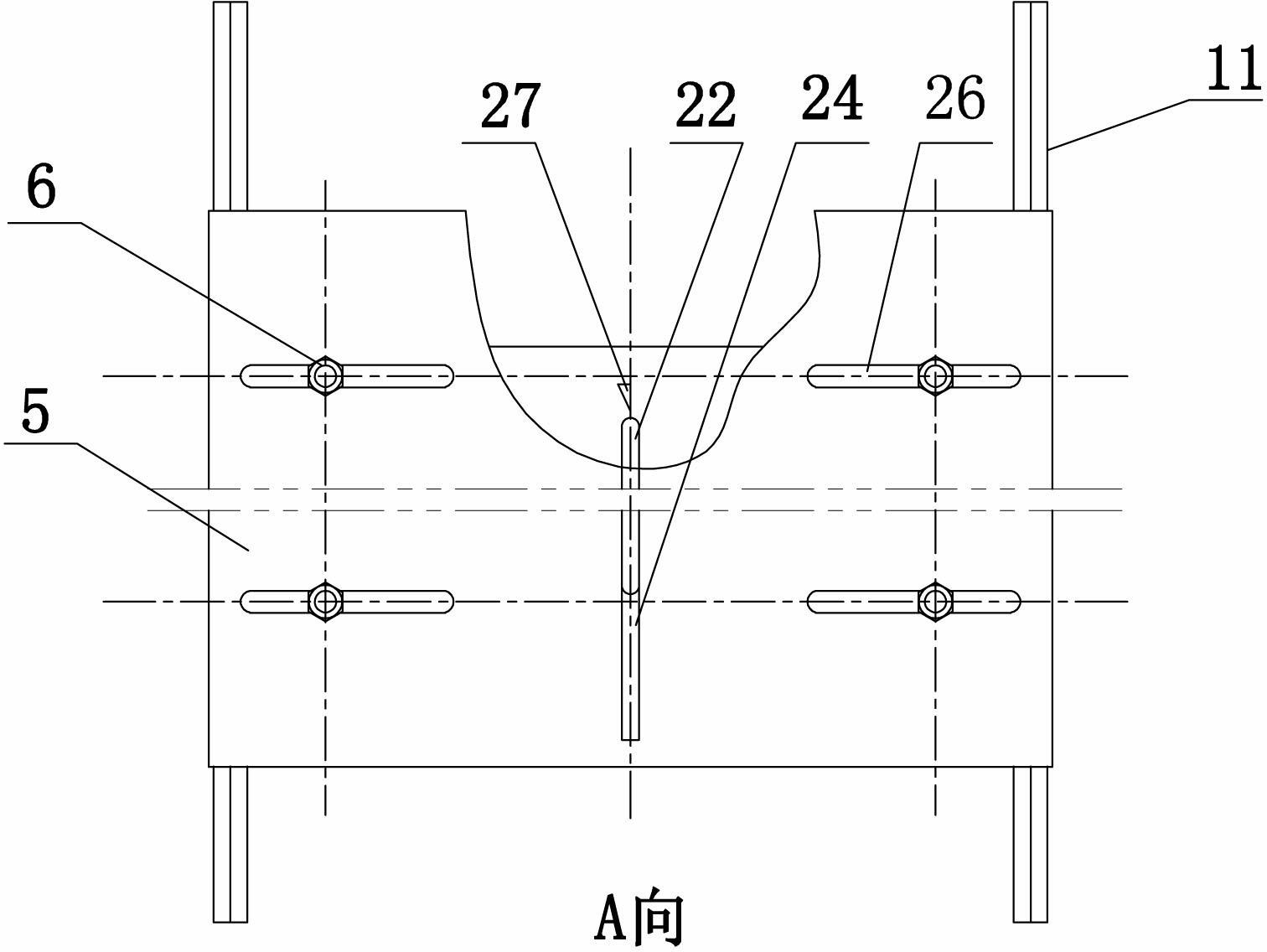

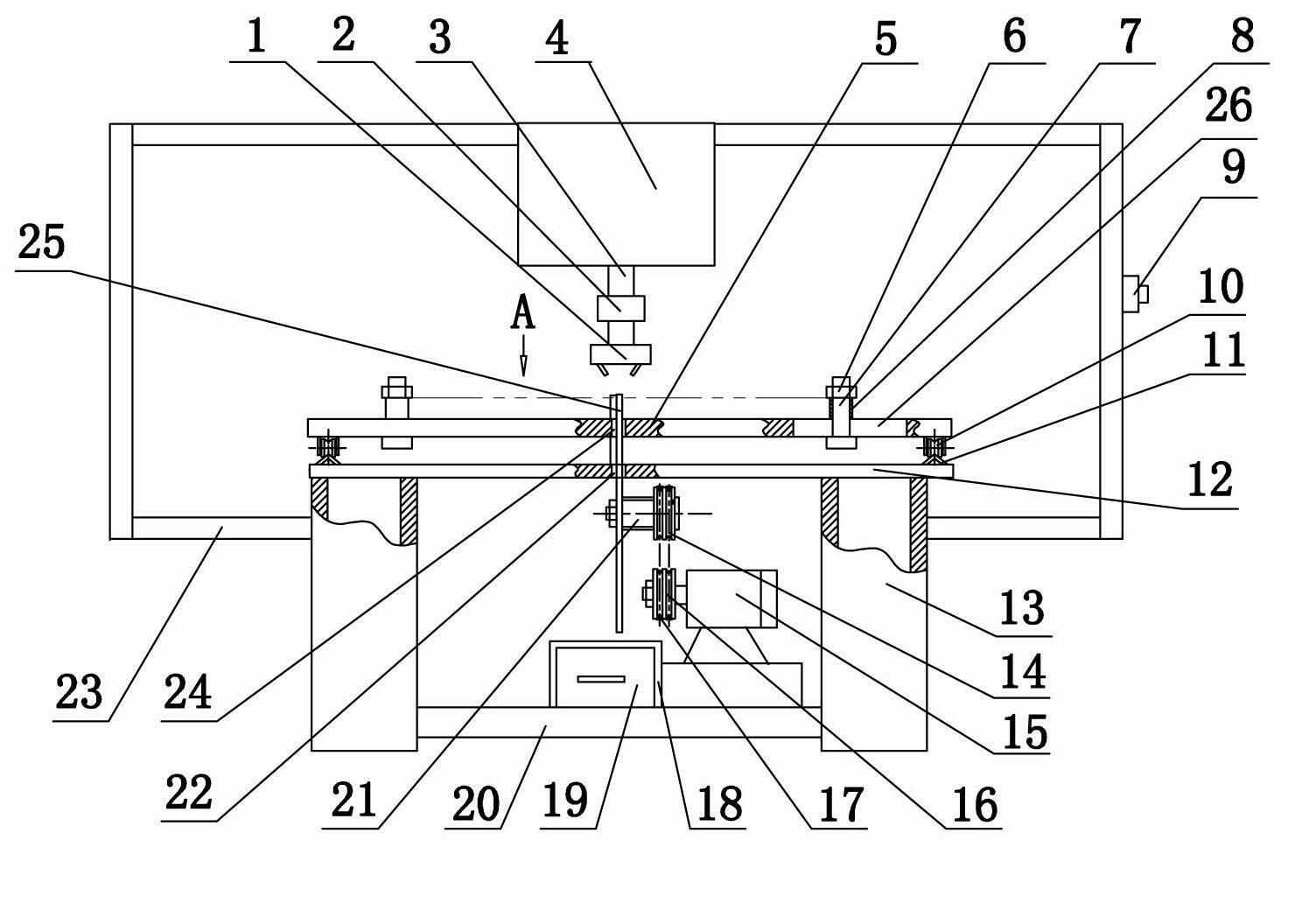

[0020] The cutting machine of dividing adhesive tape of the present invention is characterized in that by support frame, the tape cutting device that is respectively arranged on this support frame, swarf recovery device and operation platform 12, the flatbed sports car that is arranged on this operation platform 12 and is located at this The lubricating liquid spraying device above the flat sports car is composed of, the tape cutting device and the swarf recovery device are all arranged under the operating platform 12, and the operating platform 12 is provided with a longitudinal central strip hole 22. The supporting frame is composed of two supporting bases 13 and connecting base plates 20 fixedly connected to the two supporting bases 13 at both ends,

[0021] The tape cutting device is composed of a motor 15 fixed on the connecting base plate 20, a driving wheel 16 fixedly connected to the output shaft of the motor 15, a transmission V-belt 17 meshed with the driving wheel 16, a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap