Grain conveying and screening machine

A screening machine and grain technology, applied in the field of conveyors, can solve the problems of troublesome operation, low speed of grain screening, single structure and function of cleaning equipment, etc., and achieve the effect of good transportation, dust removal and convenient storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

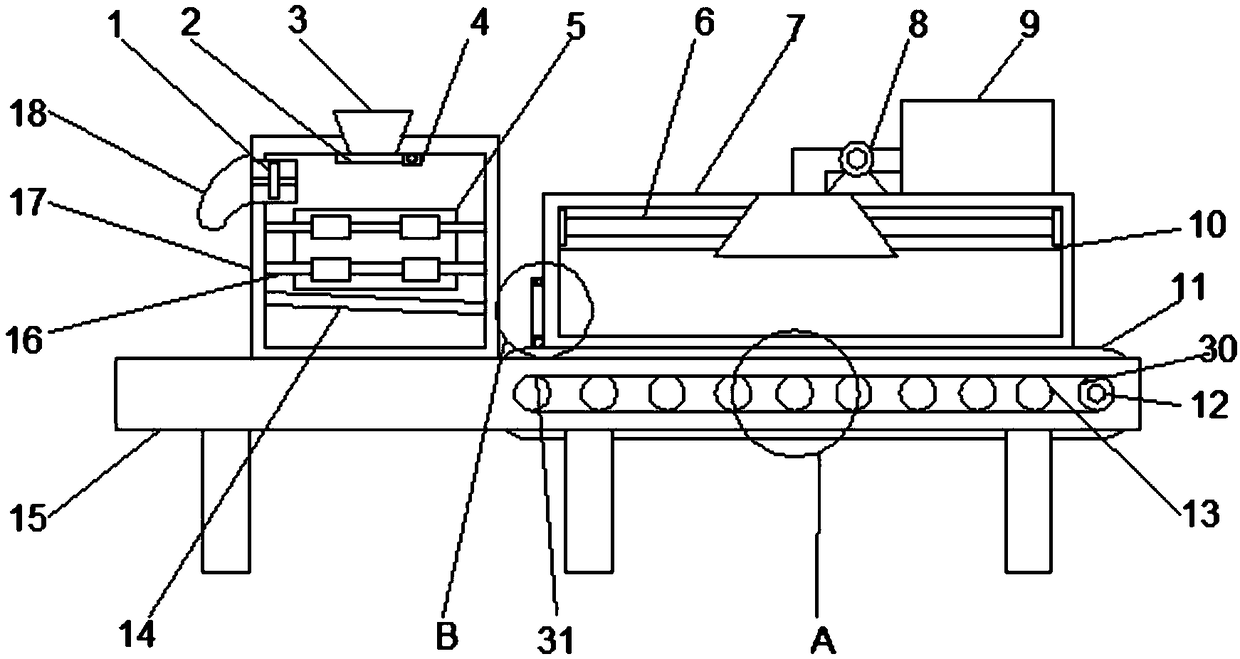

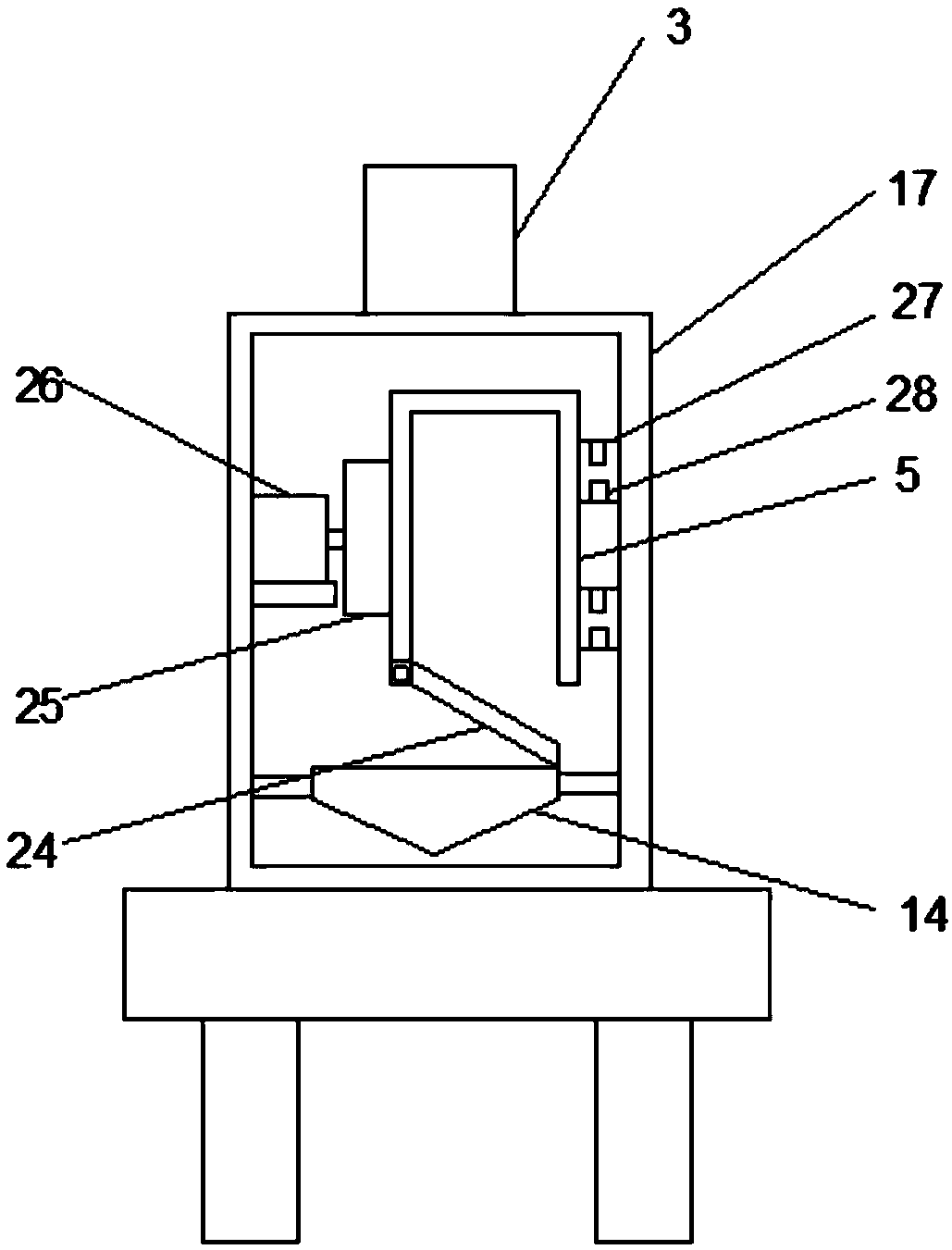

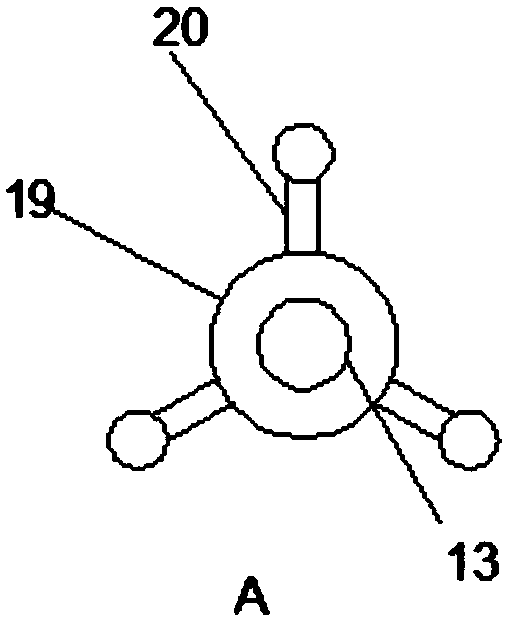

[0020] Such as Figure 1-Figure 4 As shown, a kind of grain conveying and screening machine that the present invention proposes comprises base 15 and casing 17, and the rear side of right end of base 15 is provided with first motor 12, and first motor 12 axles are connected with first pulley 30, and first belt The surface of the wheel 30 is provided with a conveyor belt 11, the first pulley 30 is connected to the second pulley 31 through the conveyor belt 11, the outer sides of the first pulley 30 and the second pulley 31 are connected to gears, and the right side surface of the base 15 is penetrated with a number of rotating rollers 13, The surfaces of the rotating rollers 13 are all connected with chains, and the chains are meshed with the gears. The upper surface of the right side of the base 15 is provided with a shielding plate 7, and the upper right corner of the shielding plate 7 is provided with a dust collection box 9, and the left end of the dust collection box 9 is prov

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap