Quick sorting machine for coal gangues with different sizes

A technology of coal gangue and sorter, which is used in sorting, solid separation, conveyor objects, etc., can solve the problems of surface damage of conveyor belt, sifting of coal gangue, stuck between the bottom of the dividing plate and the conveyor belt, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

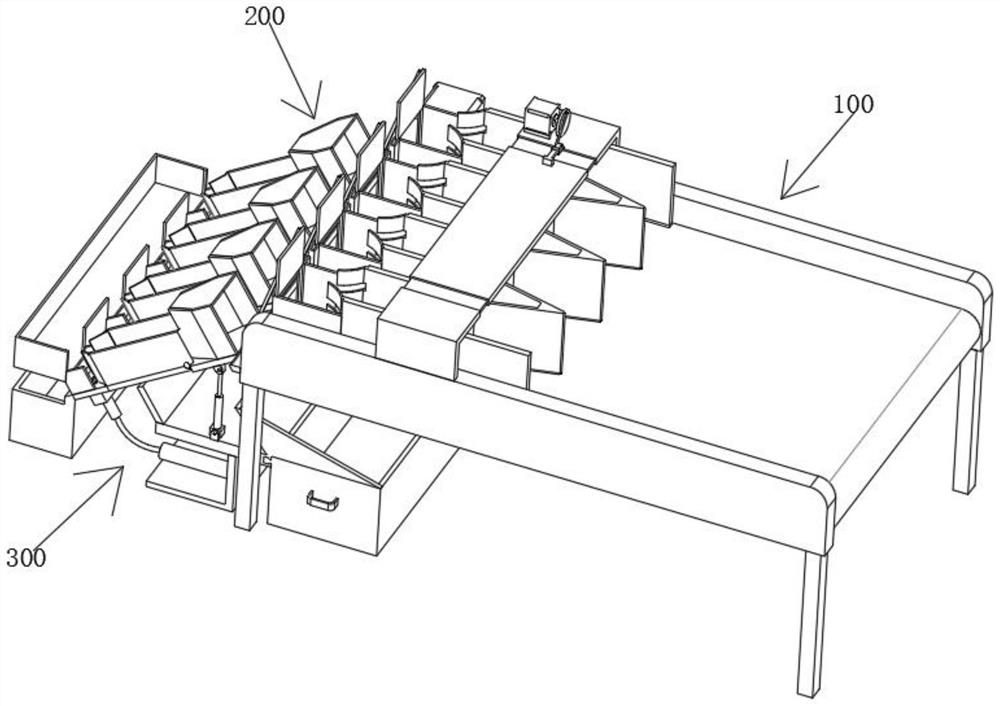

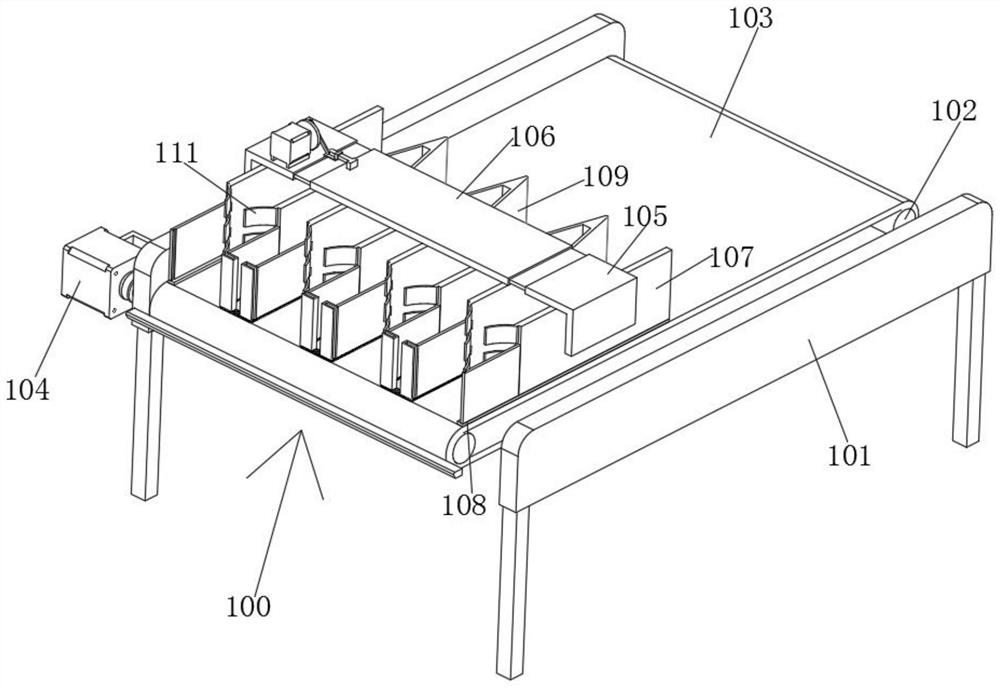

[0029] see Figure 1-7 As shown, a coal gangue rapid sorter of different sizes includes a feeding mechanism 100, one side of the feeding mechanism 100 is fixedly provided with a sieving mechanism 200, and the bottom end of the sieving mechanism 200 is fixedly provided with a blowing sieve mechanism 300;

[0030] The feeding mechanism 100 includes two supporting frames 101, the tops of the two supporting frames 101 are fixedly connected with socket plates 105, and a reciprocating plat

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap