Ceramic powder balling method and device

A ceramic powder and ball-forming technology, applied in the field of powder processing, can solve the problem that the screening device does not use screening, and achieve the effects of reducing labor intensity and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

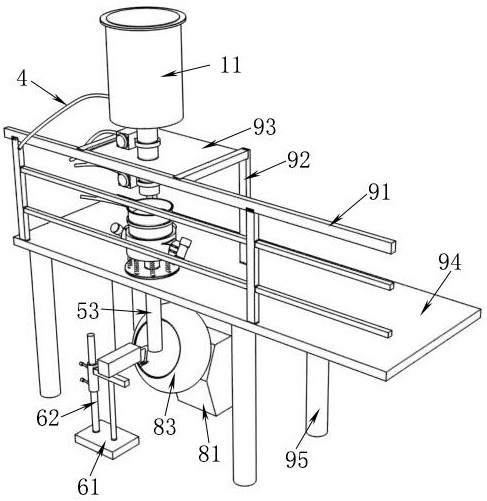

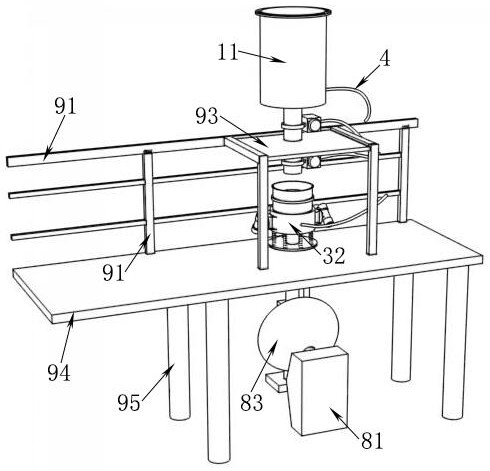

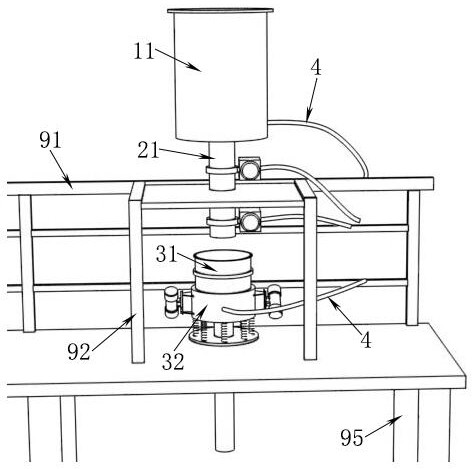

[0032] like figure 1 and figure 2 Shown, support comprises railing 91, support bar 62, flat plate 93, table board 94 and pillar 95, table board 94 is set on pillar 95, railing 91 and support bar 62 are set on table board 94, and between bar and support bar Flat plate 93 is set between 62. A quantitative feeding device is connected to the bottom of the feeding barrel, and a screening device is arranged below the quantitative feeding device. The chassis 51 of the screening device is fixedly connected to the table 94 , the quantitative feeding device is passed through the flat board 93 , and the quantitative feeding device is fixedly connected to the flat board 93 . The feeding pipe 53 passes through the table plate 94, and a sugar coating machine is arranged below the feeding pipe 53. After the screening of the two-layer sieving barrel 31 of the sieving device, the small ceramic powder of diameter enters in the holding barrel 32, and falls into the sugar coating machine along t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap