Addition process and addition equipment of coagulant for industrial wastewater

A technology for adding industrial waste water and equipment, applied in the direction of mixers, water/sewage treatment, heating water/sewage treatment, etc., can solve the problems of not being able to grasp the amount of additives well, and the performance of adding is not perfect, etc., to achieve stable and perfect treatment performance , simple structure, high practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

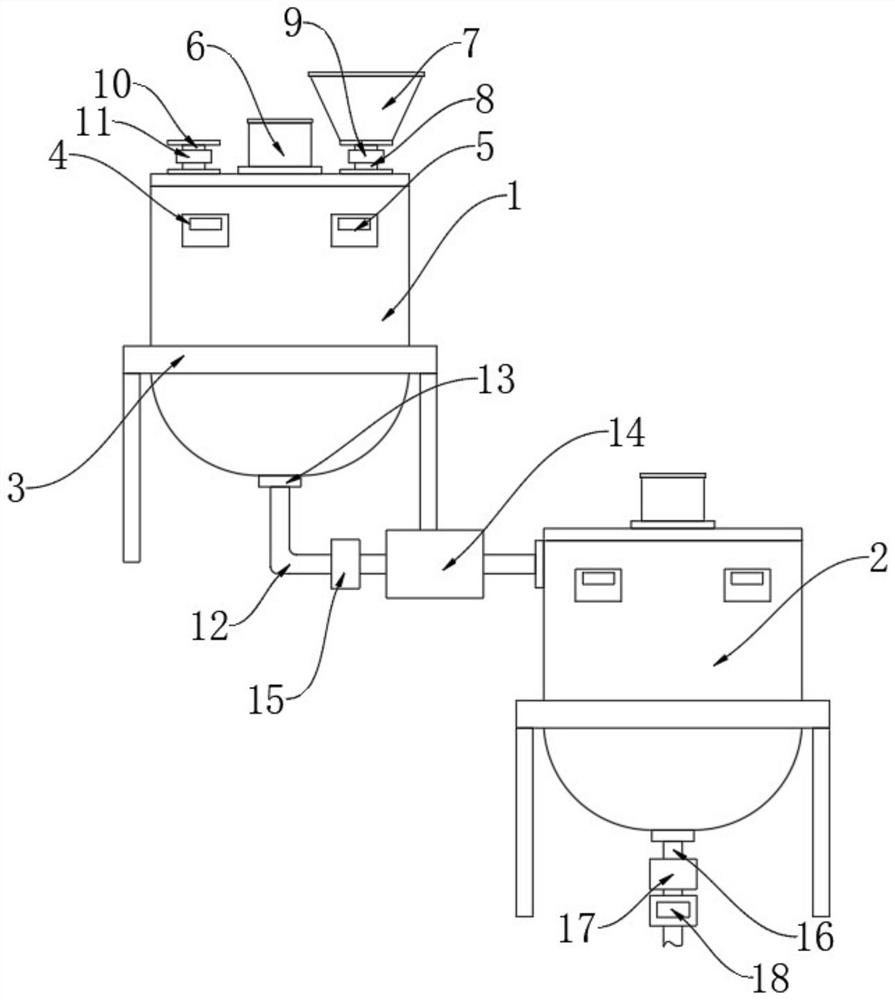

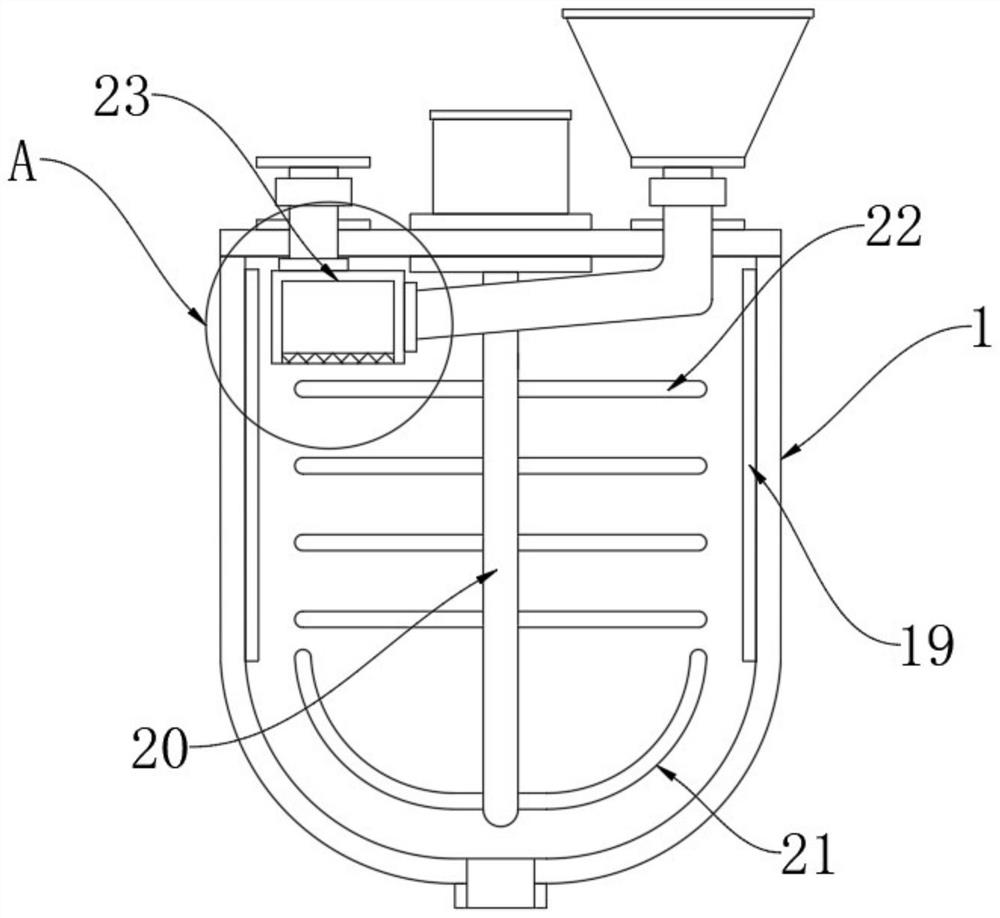

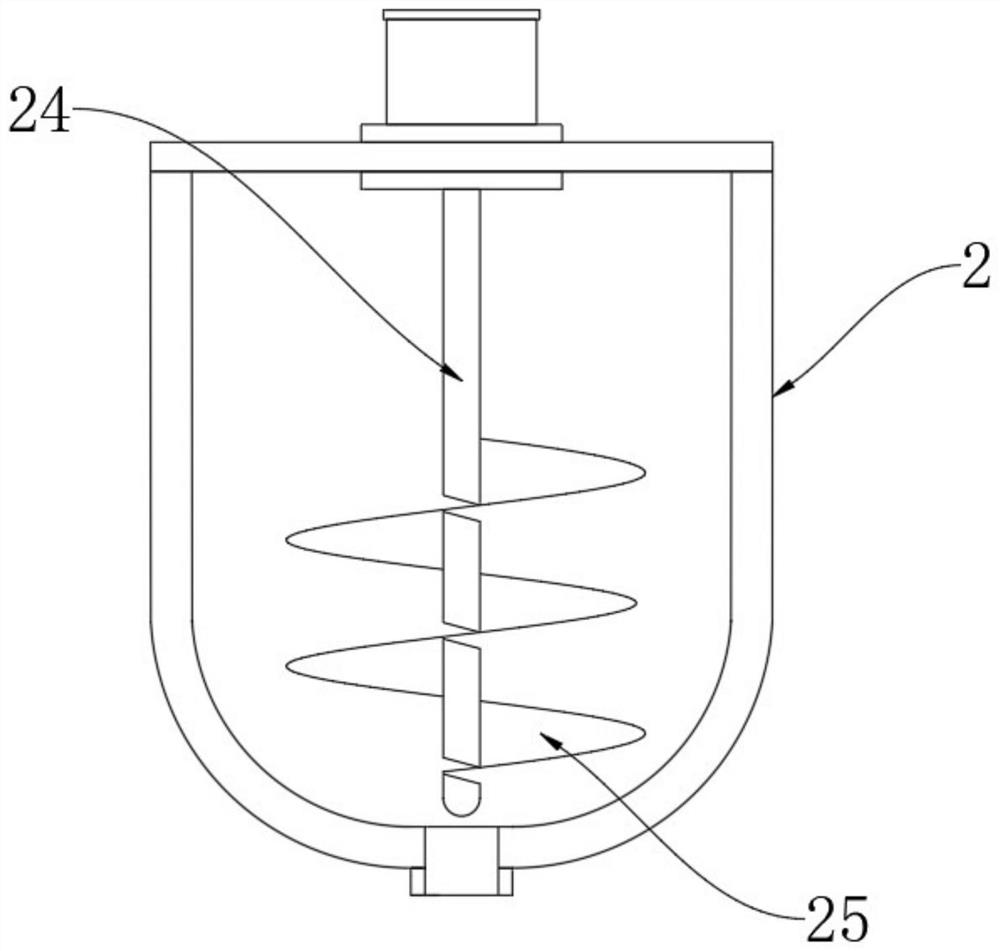

[0028] see Figure 1-4 , an embodiment provided by the present invention: a coagulant addition process for industrial wastewater, characterized in that the addition equipment includes a liquid medicine dissolution tank 1, a liquid medicine storage tank 2, a mounting bracket 3, and a thermometer 4 , liquid level gauge 5, rotating motor 6, coagulant storage tank 7, feed pipe 8, solenoid valve 9, mixed water feed pipe 10, second solenoid valve 11, outlet pipe 12, outlet pipe 13, filter 14 , flow meter 15, adding pipeline 16, third solenoid valve 17, second flow meter 18, heating block 19, stirring and rotating main rod 20, arc rotating rod 21, stirring rod 22, mixing mecha

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap